Novel direct type backlight module and LED light-emitting device thereof

A backlight module and light-emitting device technology, which is applied in the direction of optical components, light guides, optics, etc., can solve the problems of high process cost, non-vertical, and inability to control in different areas, and achieve low process cost, thinness, and picture effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

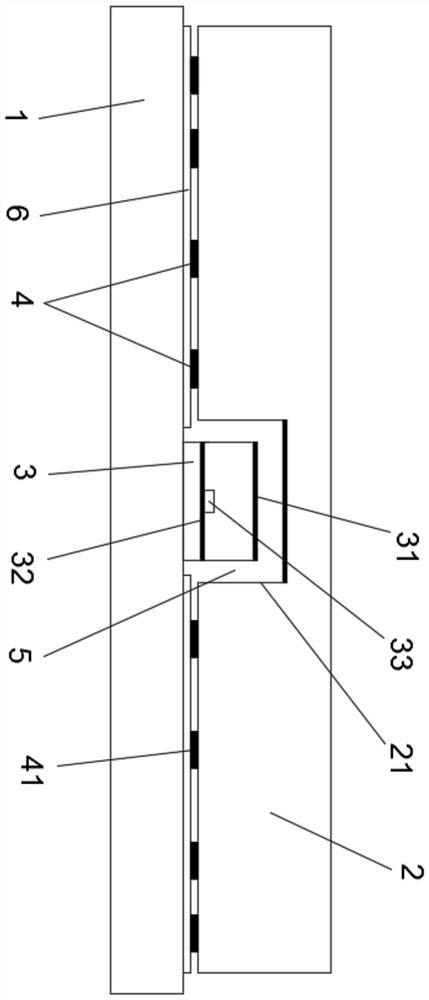

[0048] A novel direct-type backlight module LED light-emitting device, such as figure 1 As shown, it includes: a substrate 1, a light guide plate 2, LED particles 3, and a dot layer 4, the light guide plate 2 is located above the dot layer 4, the substrate 1 is located below the dot layer 4, and the LED particles 3 are fixed on the dot layer of the substrate 1. The upper surface, and the LED particles 3 are arranged in the LED installation chamber 21 of the light guide plate 2, the lower surface of the LED installation chamber 21 is flush with the lower surface of the light guide plate 2, and the upper and lower parts of the LED particles 3 are provided with a small reflective layer 31. Light is emitted from the surroundings of the LED particles 3 .

[0049] There is a gap 5 between the LED particle 3 and the upper surface and surroundings of the LED installation chamber 21, and the upper surface of the LED installation chamber 21 is provided with a reflective layer, which is ...

Embodiment 2

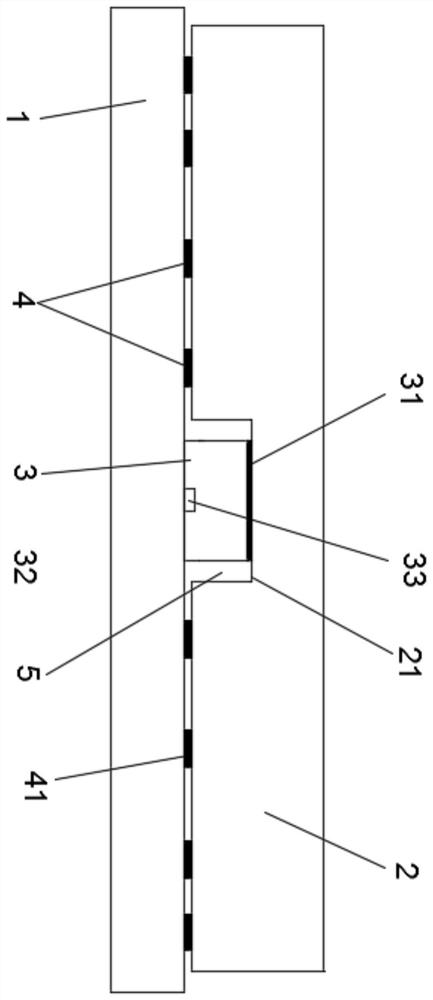

[0053] A novel direct-type backlight module LED light-emitting device, such as figure 2 As shown, it includes: a substrate 1, a light guide plate 2, LED particles 3, and a dot layer 4, the light guide plate 2 is located above the dot layer 4, the substrate 1 is located below the dot layer 4, and the LED particles 3 are fixed on the dot layer of the substrate 1. The upper surface, and the LED particles 3 are arranged in the LED installation chamber 21 of the light guide plate 2, the lower surface of the LED installation chamber 21 is flush with the lower surface of the light guide plate 2, and the upper and lower parts of the LED particles 3 are provided with a small reflective layer 31. Light is emitted from the surroundings of the LED particles 3 .

[0054] There is no gap between the LED particle 3 and the upper surface of the LED installation chamber 21 , but there is a gap 5 around the LED particle 3 and the LED installation chamber 21 , and the gap 5 is filled with a tra...

Embodiment 3

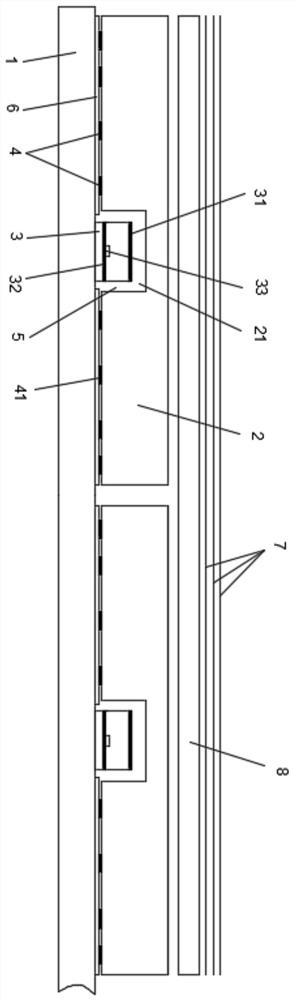

[0058] A new type of direct-lit backlight module, such as image 3 As shown, it includes: a substrate 1, a light guide plate 2, LED particles 3, and a dot layer 4, the light guide plate 2 is located above the dot layer 4, the substrate 1 is located below the dot layer 4, and the LED particles 3 are fixed on the dot layer of the substrate 1. The upper surface, and the LED particles 3 are arranged in the LED installation chamber 21 of the light guide plate 2, the lower surface of the LED installation chamber 21 is flush with the lower surface of the light guide plate 2, and the upper and lower parts of the LED particles 3 are provided with a small reflective layer 31 , light is emitted from the surroundings of the LED particles 3 , and other optical films 7 are also included, and the other optical films 7 are located above the light guide plate 2 .

[0059] There are gaps 5 between the LED particles 3 and the upper surface and surroundings of the LED installation chamber 21 , an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com