Wafer baking device

A technology for baking devices and wafers, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as unfavorable pick-and-place processes, wafer fluctuations on the heating plate, slipping or slipping, etc., to overcome defects Influence, improve stability, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

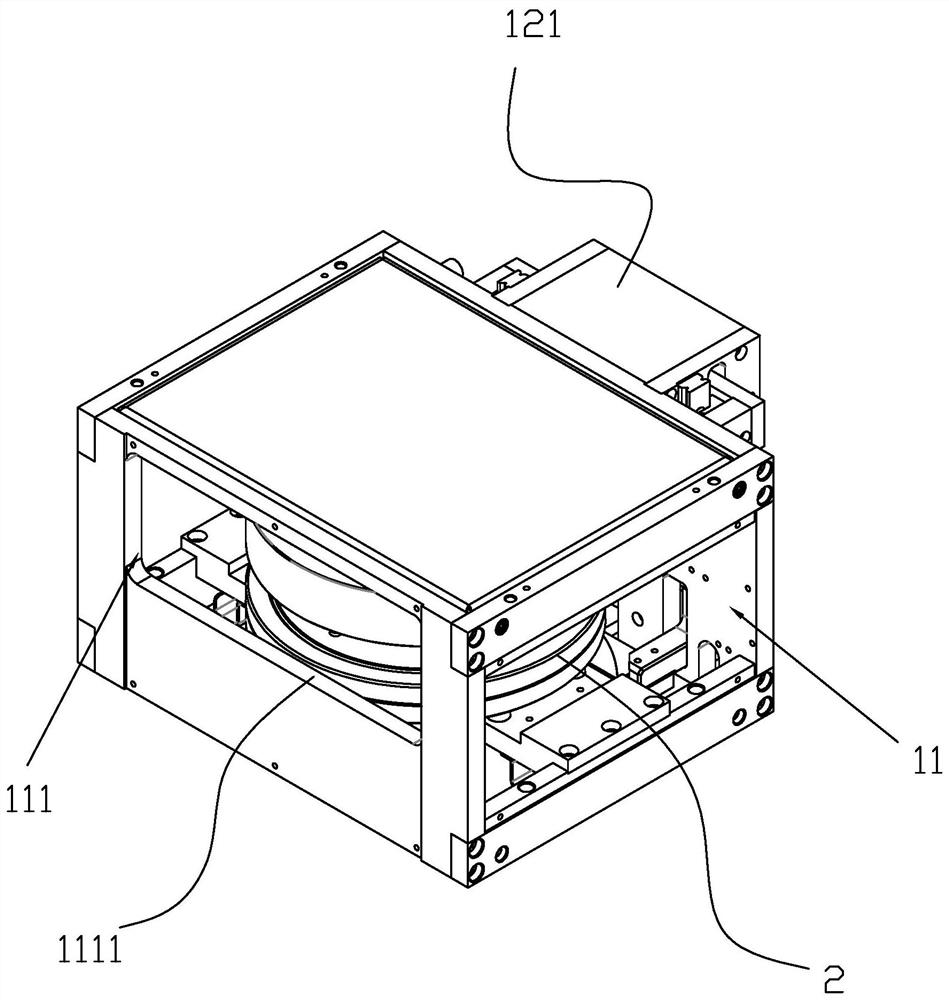

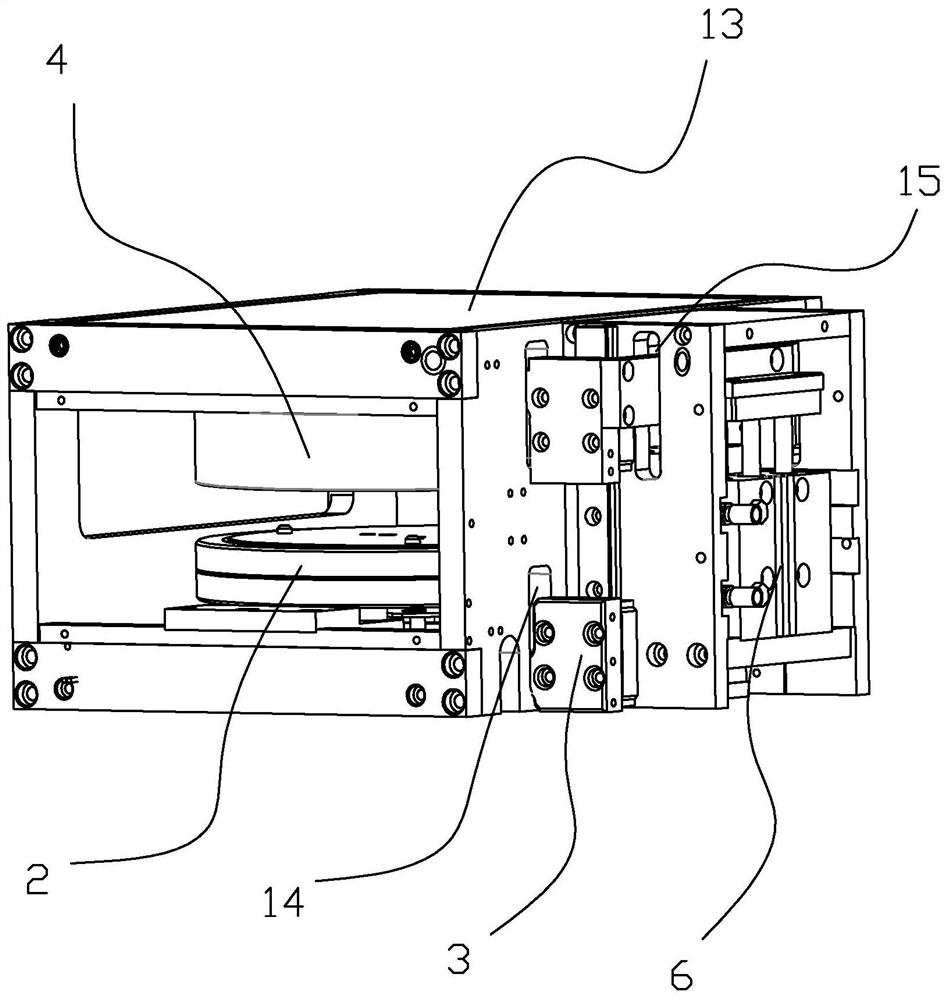

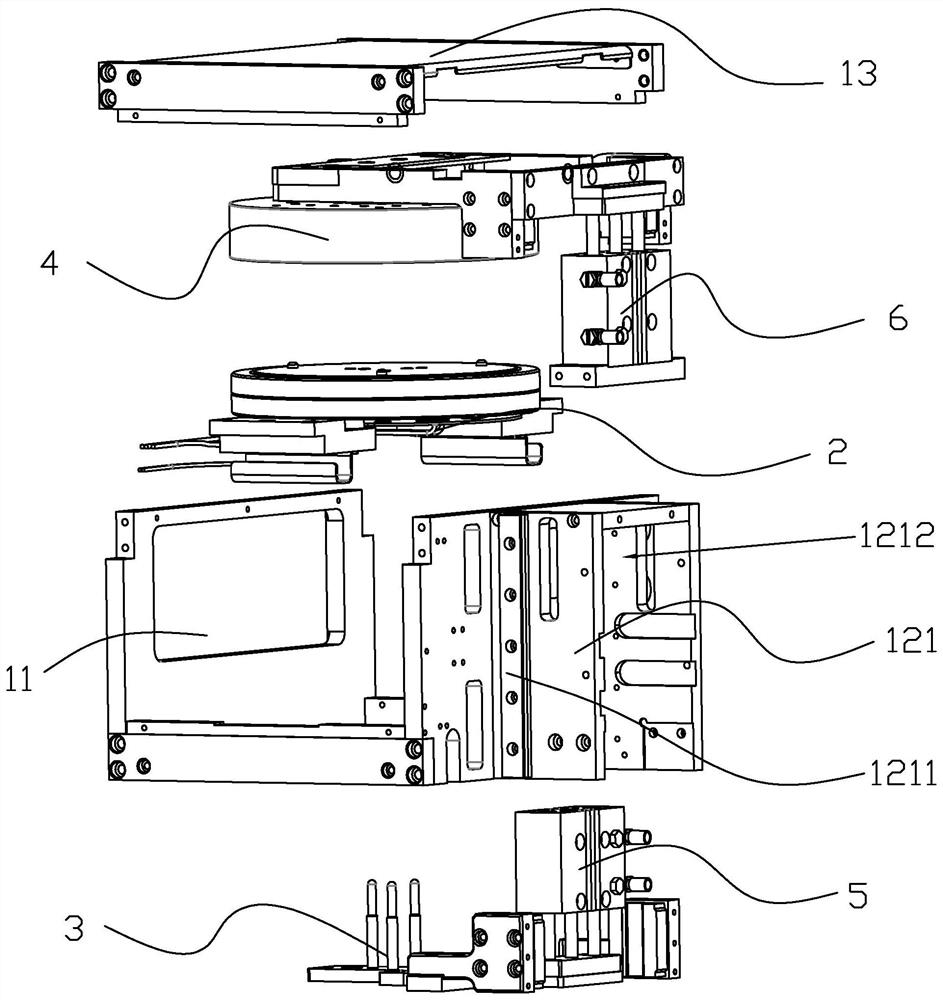

[0050] refer to Figure 1-Figure 3As shown, the present invention provides a wafer baking device, which includes a housing 1 , a heater 2 , an ejection mechanism 3 and a sealing mechanism 4 . Wherein, the shell 1 has an inner cavity 11, and the inner cavity 11 has at least one opening 111, and the opening 111 is used for the entry and exit of the wafer, and the surface of the shell 1 is provided with a lifting guide rail 1211; the heater 2 is arranged in the inner cavity 11 for Carrying and heating the wafer; the ejection mechanism 3 is slidably connected to the lifting guide rail 1211 so as to perform lifting movement along the lifting guide rail 1211, the ejection mechanism 3 has a thimble 32, and the thimble 32 is installed in the heater 2, and the thimble 32 can follow the described Part of the lifting movement extends out of the heater 2; the sealing mechanism 4 is arranged above the heater 2, and is slidably connected to the lifting guide rail 1211 so as to perform lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com