Quaternary ammonium and imidazole cross-linked anion exchange membrane for fuel cell and preparation method thereof

An anion exchange membrane, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as high price and restricting the promotion and development of proton exchange membrane fuel cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

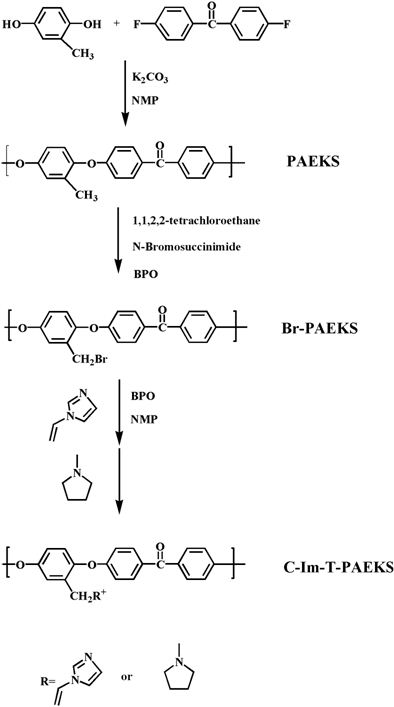

[0031] The present invention also provides a preparation method of a quaternary ammonium and imidazole cross-linked anion exchange membrane for a fuel cell, comprising the following steps:

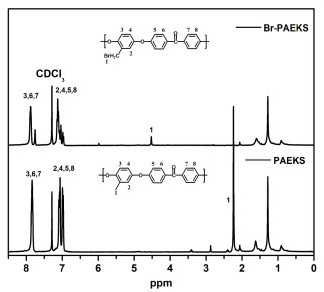

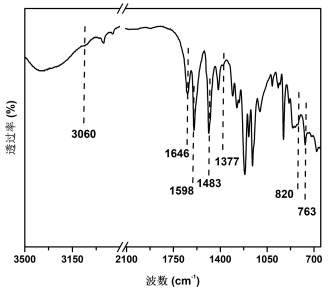

[0032] Step 1: Dissolving the polymer in tetrachloroethane, adding benzoyl peroxide and N-bromosuccinimide in an 80-degree oil bath and stirring for 5 hours, discharging in alcohol to obtain a light yellow floc;

[0033] Step 2: dissolving the light yellow floc obtained in the first step in a solvent to obtain a clear orange solution;

[0034] Step 3: Add benzoyl peroxide, 1-vinylimidazole and 1-methylpyrrolidine to the solution obtained in step 2 and stir for 12 to 24 hours to obtain a dark yellow film-forming solution. The anion exchange membrane is grafted with imidazole groups Prepared with a different molar ratio from the quaternary ammonium group, the molar ratio of the grafted imidazole group to the quaternary ammonium group is: a:b (a, b are both integers from 1 to 9 and a+b=10); ...

Embodiment 1

[0039] (1) Dissolve the polymer in tetrachloroethane, add benzoyl peroxide and N-bromosuccinimide and stir in an 80-degree oil bath for 5 hours, discharge in alcohol, and obtain a light yellow floc;

[0040] (2) Dissolving the light yellow floc obtained in step (1) in a solvent to obtain a clear orange solution;

[0041] (3) Add the solution obtained in step (2) to benzoyl peroxide, 1-vinylimidazole and 1-methylpyrrolidine (the molar ratio of 1-vinylimidazole to 1-methylpyrrolidine is 5:5) and stir After 12 to 24 hours, dark yellow film-forming liquid is obtained. The anion exchange membrane is prepared according to different molar ratios of grafted imidazole groups and quaternary ammonium groups. The molar ratio of grafted imidazole groups to quaternary ammonium groups is: a:b(a , b are integers from 1 to 9 and a+b=10);

[0042] (4) Cast the dark yellow film-forming solution obtained in step (3) on a glass plate to form a film, then put it in a constant temperature box, dry ...

Embodiment 2

[0045](1) Dissolve the polymer in tetrachloroethane, add benzoyl peroxide and N-bromosuccinimide and stir in an 80-degree oil bath for 5 hours, discharge in alcohol, and obtain a light yellow floc;

[0046] (2) Dissolving the light yellow floc obtained in step (1) in a solvent to obtain a clear orange solution;

[0047] (3) Add the solution obtained in step (2) to benzoyl peroxide, 1-vinylimidazole and 1-methylpyrrolidine (the molar ratio of 1-vinylimidazole to 1-methylpyrrolidine is 4:6) and stir After 12 to 24 hours, dark yellow film-forming liquid is obtained. The anion exchange membrane is prepared according to different molar ratios of grafted imidazole groups and quaternary ammonium groups. The molar ratio of grafted imidazole groups to quaternary ammonium groups is: a:b(a , b are integers from 1 to 9 and a+b=10);

[0048] (4) Cast the dark yellow film-forming solution obtained in step (3) on a glass plate to form a film, then put it in a constant temperature box, dry a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com