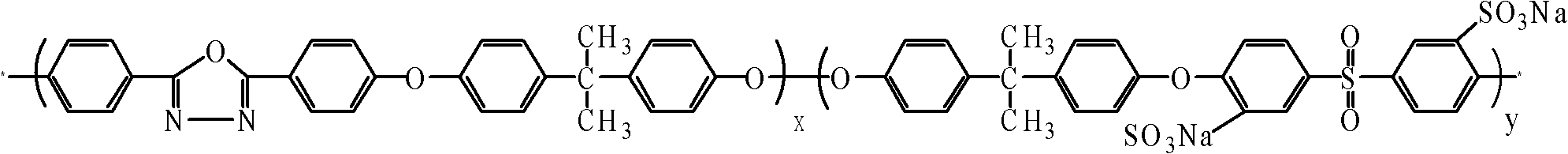

1, 3, 4-oxadiazole ring containing poly (aromatic ether sulfone) medium-high temperature proton exchange membrane and preparation method thereof

A technology of proton exchange membrane and polyaryl ether sulfone is applied in the field of high molecular polymer proton exchange membrane and its preparation, which can solve the problems of decreased conductivity, long preparation time, uncontrollable degree of sulfonation, etc., and achieve accurate degree of sulfonation. Controllable, simple preparation method, and anti-shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

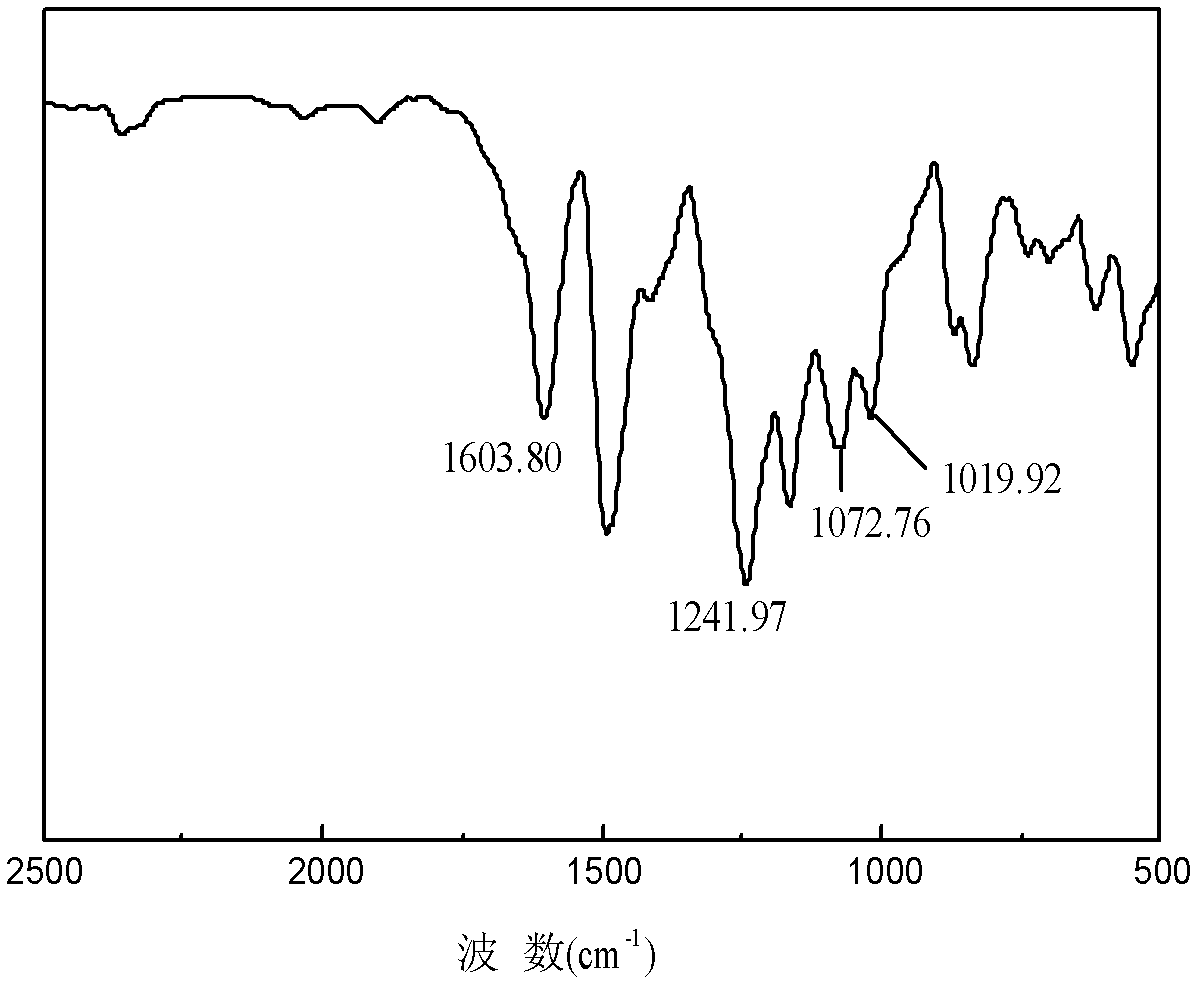

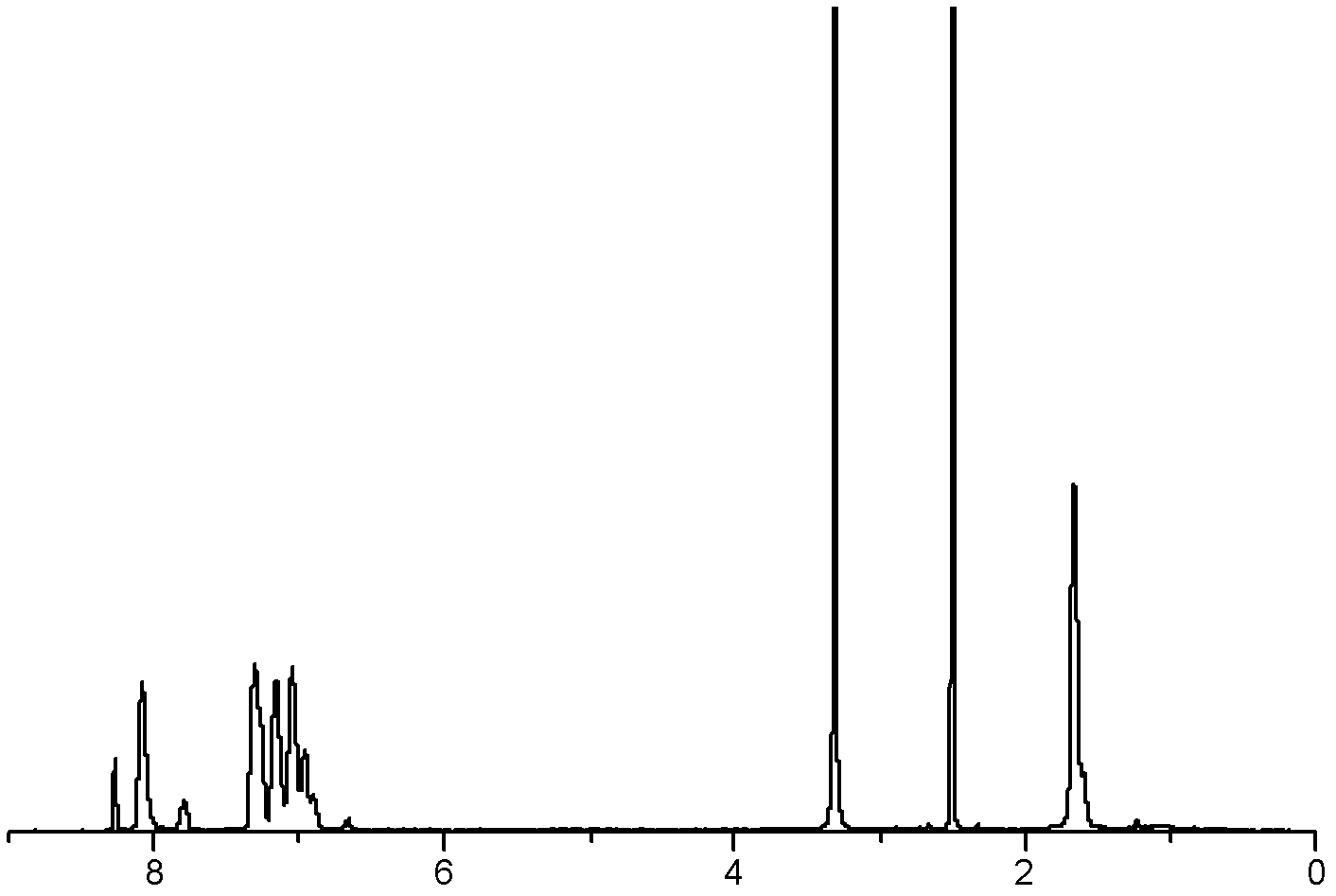

Embodiment 1

[0033] Under the protection of an inert gas, 2.80g of 4-fluorobenzoic acid, 1.30g of hydrazine sulfate and 50g of polyphosphoric acid were added to the reactor to form a mixture. The mixture was reacted at 150°C for 4h, then heated to 200°C for 3h to obtain a white needle Product fluorine-terminated monomer, add 1.23g 2,5-2(4-fluorophenyl)-1,3,4-oxadiazole, 0.59g 3,3'-sodium disulfonate-4 , 4'-difluorodiphenyl sulfone, 1.37g bisphenol A, K 2 CO 3 As a salt-forming agent, the mixture of 6ml N-methylpyrrolidone and 6ml N-cyclohexylpyrrolidone is used as a solvent, 10ml of toluene is used as a water-carrying agent, and the solid content is 30%. Carry water at 130°C for 4 hours, then distill the toluene, and the temperature rises to 190 React at ℃ for 20 hours to get the reaction product, pour the product into acetone to precipitate, filter, wash with water and dry at 60℃ for 24 hours, dissolve the pure polymer in NMP to get a polymer solution, put the polymer solution on a clean...

Embodiment 2

[0035]Under the protection of an inert gas, 5.60g of 4-fluorobenzoic acid, 2.60g of hydrazine sulfate and 80g of polyphosphoric acid were added to the reactor to form a mixture. The mixture was reacted at 160°C for 6h, and then heated to 200°C for 2h to obtain white needles. Product fluorine-terminated monomer, add 1.80g 2,5-2(4-fluorophenyl)-1,3,4-oxadiazole, 1.47g 3,3'-sodium disulfonate-4 , 4'-difluorodiphenyl sulfone, 2.28g bisphenol A, K 2 CO 3 As a salt-forming agent, a mixture of 5.25ml N-methylpyrrolidone and 5.25ml N-cyclohexylpyrrolidone is used as a solvent, 10ml of toluene is used as a water-carrying agent, and the solid content is 30%. Carry water at 130°C for 4 hours, then distill the toluene, and the temperature rises React at 190°C for 25 hours to obtain the reaction product, pour the product into acetone to precipitate, filter, wash with water, and dry at 60°C for 24 hours, dissolve the pure polymer in NMP to obtain a polymer solution, put the polymer solutio...

Embodiment 3

[0039] Under the protection of an inert gas, 8.40g of 4-fluorobenzoic acid, 3.90g of hydrazine sulfate and 120g of polyphosphoric acid were added to the reactor to form a mixture. The mixture was reacted at 150°C for 6h and then heated to 200°C for 3h to obtain a white needle Product fluorine-terminated monomer, add 0.93g 2,5-2(4-fluorophenyl)-1,3,4-oxadiazole, 1.18g 3,3'-sodium disulfonate-4 , 4'-difluorodiphenyl sulfone, 1.37g bisphenol A, K 2 CO 3 As a salt-forming agent, a mixture of 5.8ml N-methylpyrrolidone and 5.8ml N-cyclohexylpyrrolidone is used as a solvent, 10ml of toluene is used as a water-carrying agent, and the solid content is 30%. Carry water at 130°C for 4 hours, then distill the toluene, and the temperature rises React at 180°C for 30 hours to obtain a reaction product, which is poured into acetone to precipitate, filtered, washed with water, and dried at 60°C for 24 hours, and the pure polymer is dissolved in NMP to obtain a polymer solution, which is plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com