Cross-linked aminosulfonated polyfluorene ether sulfone nitrile proton exchange membrane material for fuel cells, preparation method and application thereof

A technology of aminosulfonated polyfluorene ether and proton exchange membrane, which is applied in the field of proton exchange membrane, can solve the problems of not meeting the requirements of direct methanol fuel cells, insufficient dimensional stability, and insufficient comprehensive performance, so as to maintain dimensional stability and mechanical Performance, Methanol permeation resistance, Dimensional stability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Dissolve 13.84g of p-nitroaniline in a mixed solution of 30mL of distilled water and 30mL of absolute ethanol, then add concentrated hydrochloric acid with a mass fraction of 38%, to obtain a p-nitroaniline solution, slowly add 34mL of concentrated hydrochloric acid; then 7.6g of Dissolve sodium nitrate in 40mL of distilled water; then add the sodium nitrite solution dropwise to the above-mentioned p-nitroaniline solution, and react at 0-5°C to prepare the diazonium salt solution;

[0032] Add 8.64g p-benzoquinone and 25.46g sodium bicarbonate to 100mL distilled water to form a mixture of p-benzoquinone and sodium bicarbonate, add the above-mentioned diazonium salt solution containing p-nitroaniline to p-benzoquinone and bicarbonate In the sodium mixed solution, react for 5 hours after the dropwise addition, control the reaction temperature at 10°C to obtain the mixed solution, filter the mixed solution under reduced pressure, and then wash it with distilled water 4 time...

Embodiment 2

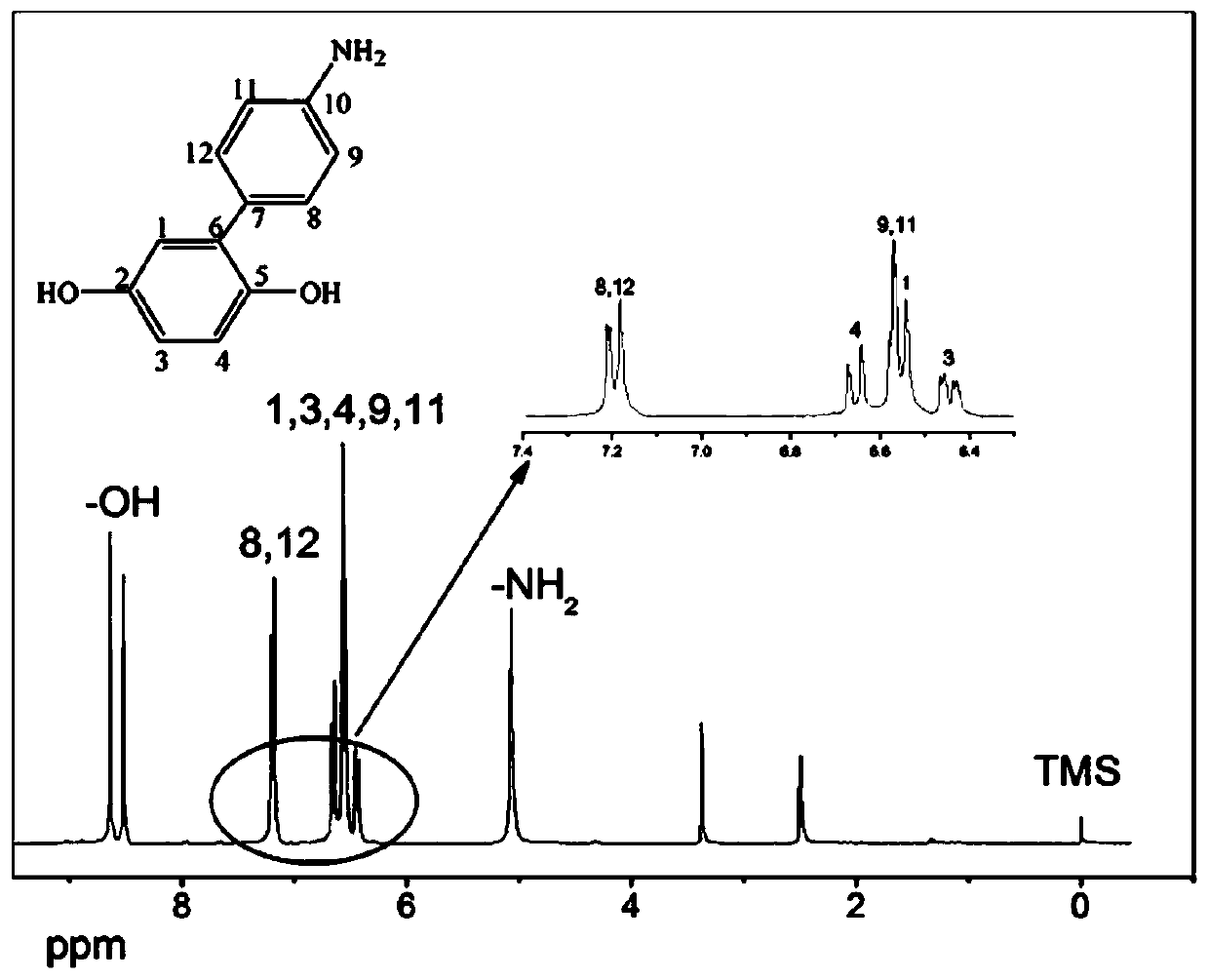

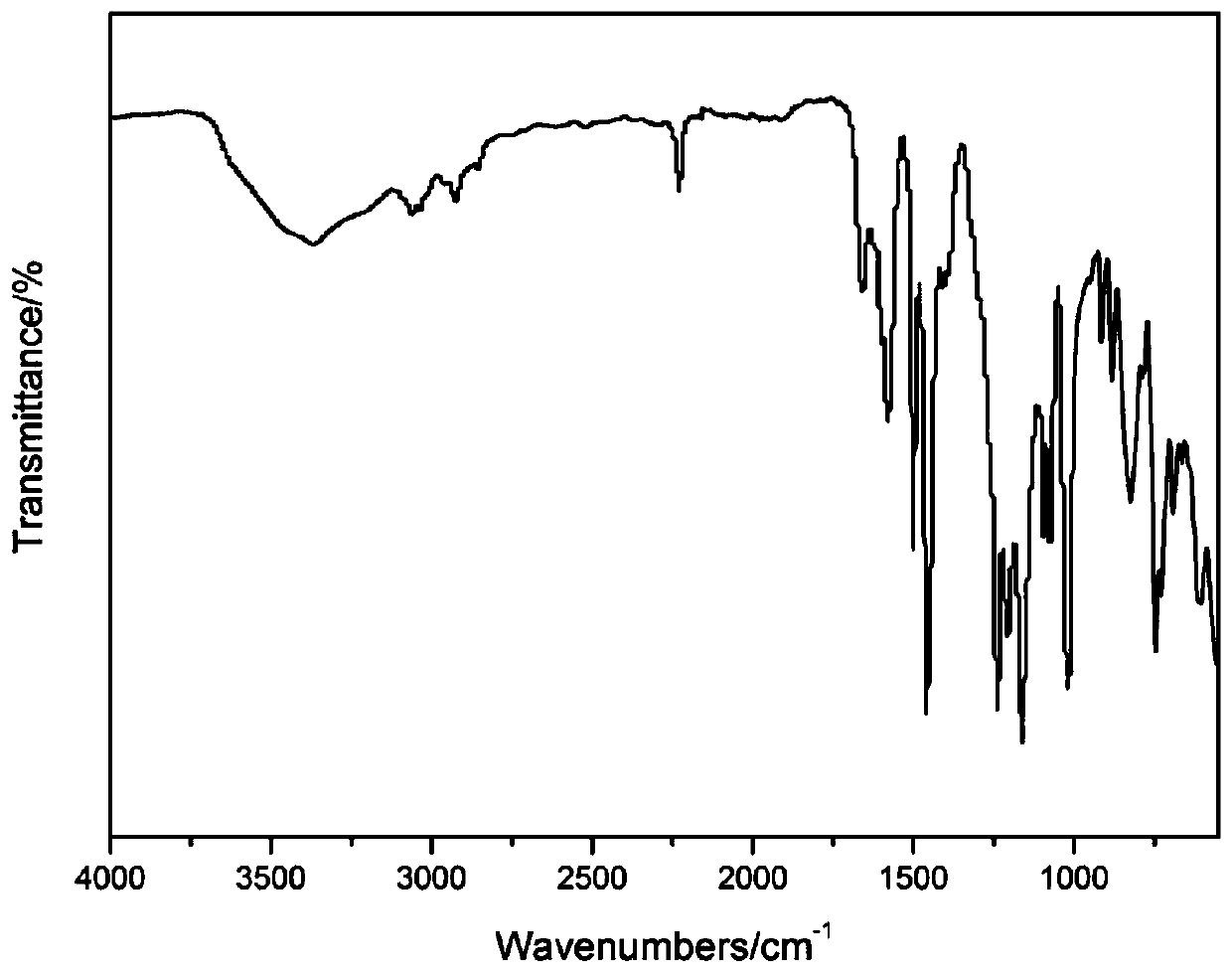

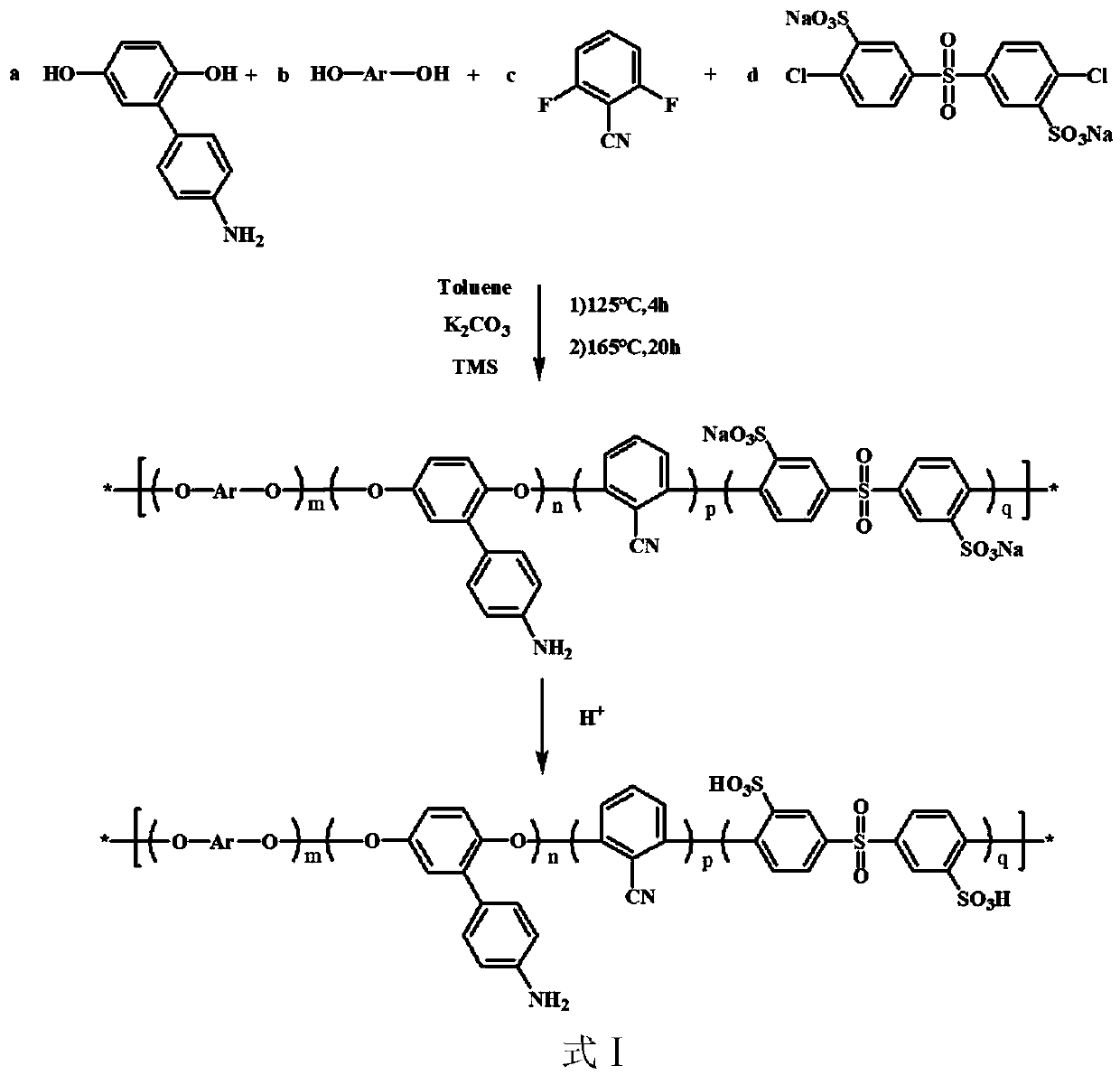

[0035] (1) Under nitrogen protection, add 0.003mol (0.603g) 4-aminophenylhydroquinone, 0.012mol (4.20492g ) bisphenol fluorene, 0.0105mol (1.46055g) 2,6-difluorobenzonitrile, 0.0045mol (2.2095g) 3,3′-sodium disulfonate-4,4′-dichlorodiphenylsulfone, 20mL sulfolane , 2.5875g potassium carbonate, 15mL toluene, reflux at 128°C, add water for 4 hours, let off the water-carrying agent; raise the temperature to 170°C, distill the toluene, continue the reaction for 10 hours, discharge the material in water, and obtain a strip-shaped polymer The obtained strip polymer was crushed with a masher, boiled 6 times with distilled water, and dried in a vacuum oven at 40°C for 48 hours; 7.9 g of polyfluorene ether sulfone nitrile copolymer containing aminosulfonated was obtained.

[0036] (2) Dissolve 1.0 g of polyfluorene ether sulfonenitrile copolymer containing aminosulfonate in 10 mL of N,N-dimethylformamide (DMF), and stir the mixed solution for 8 hours to obtain a film-forming solution; ...

Embodiment 3

[0040] (1) Under nitrogen protection, add 0.0015mol (0.3015g) 4-aminophenylhydroquinone, 0.0135mol (4.730535g ) bisphenol fluorene, 0.0105mol (1.46055g) 2,6-difluorobenzonitrile, 0.0045mol (2.2095g) 3,3′-sodium disulfonate-4,4′-dichlorodiphenylsulfone, 20mL sulfolane , 2.5875g potassium carbonate, 15mL toluene, reflux at 128°C, add water for 4 hours, let off the water-carrying agent; raise the temperature to 170°C, distill the toluene, continue the reaction for 10 hours, discharge the material in water, and obtain a strip-shaped polymer The obtained strip polymer was crushed with a masher, boiled 6 times with distilled water, and dried in a vacuum oven at 40° C. for 48 hours; 8.1 g of polyfluorene ether sulfone nitrile copolymer containing aminosulfonated was obtained.

[0041] (2) Dissolve 1.0 g of polyfluorene ether sulfonenitrile copolymer containing aminosulfonate in 10 mL of N,N-dimethylformamide (DMF), and stir the mixed solution for 8 hours to obtain a film-forming liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com