Transformer substation monitoring device

A technology for monitoring devices and substations, applied to switchgear, electrical components, etc., can solve the problems of low accuracy and cumbersome manual monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 Substation monitoring device

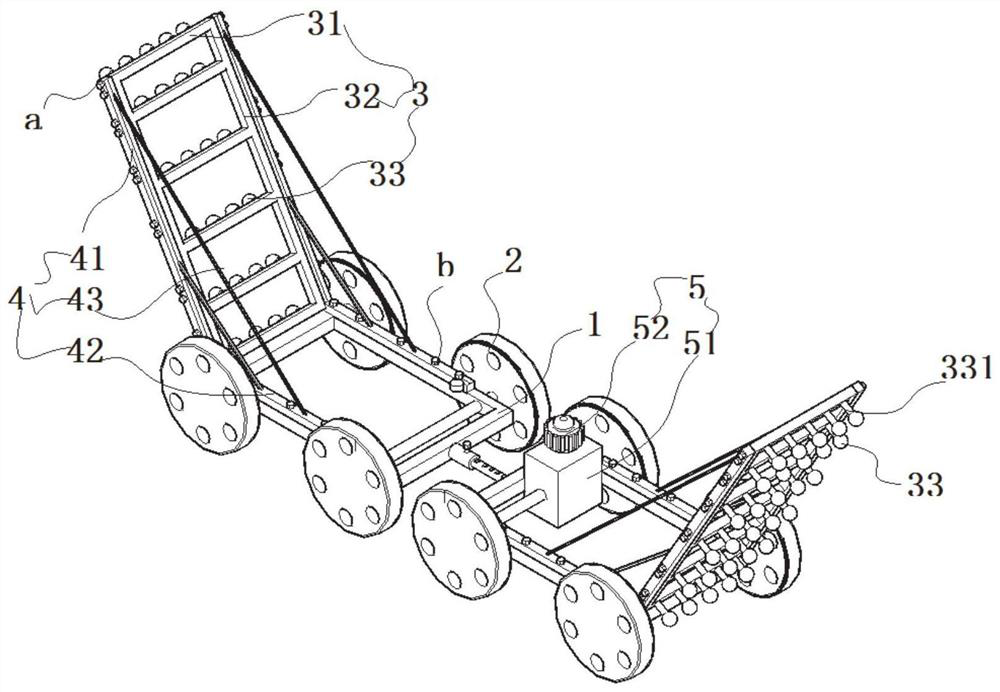

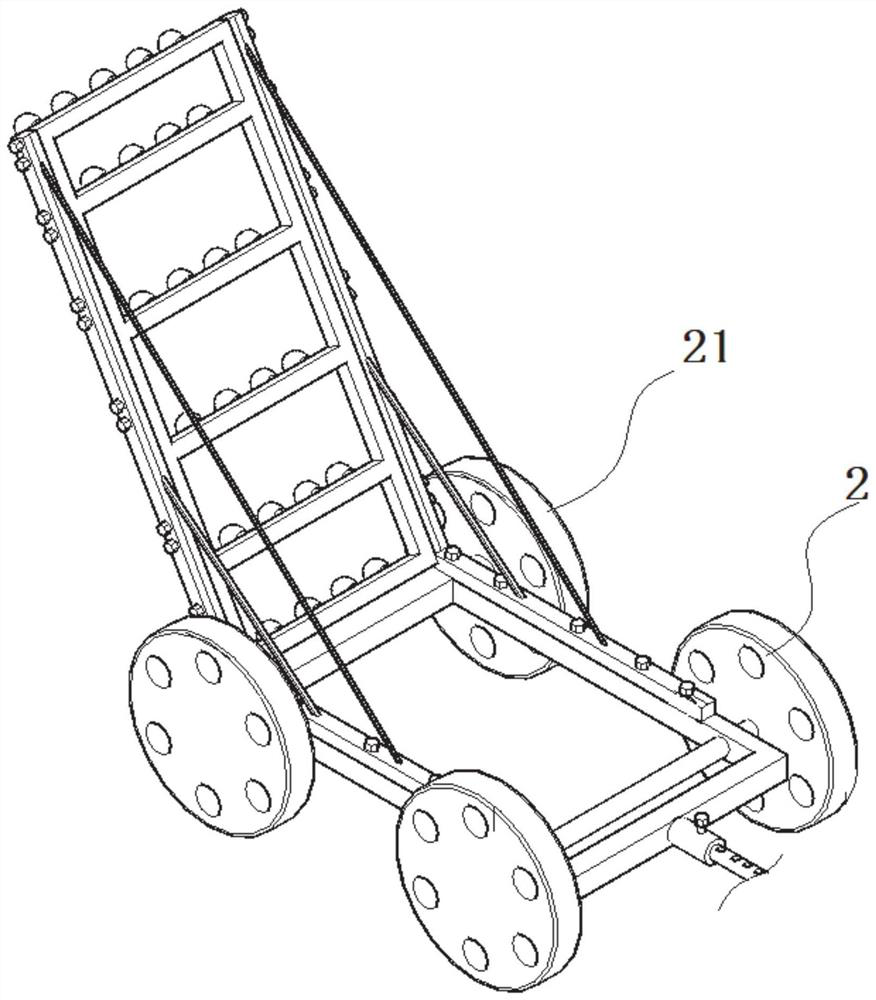

[0045] Such as Figure 1-8 As shown, a substation monitoring device includes monitoring components arranged symmetrically on the left and right sides;

[0046] The monitoring components are connected by telescopic elements 6;

[0047] The monitoring components all include a rectangular rack bar 1, and the front and rear sides of the top of the rectangular rack bar 1 are equipped with suspensions 4 arranged at intervals before and after;

[0048] The suspension 4 includes a horizontal portion 42 assembled on the rectangular frame rod 1, and the left side of the horizontal portion 42 is inclined upwardly provided with an inclined portion 41;

[0049] A monitoring component 3 is installed between the inclined parts 41, and the monitoring part 3 includes a rectangular mounting rod 32 assembled on the inclined part 41;

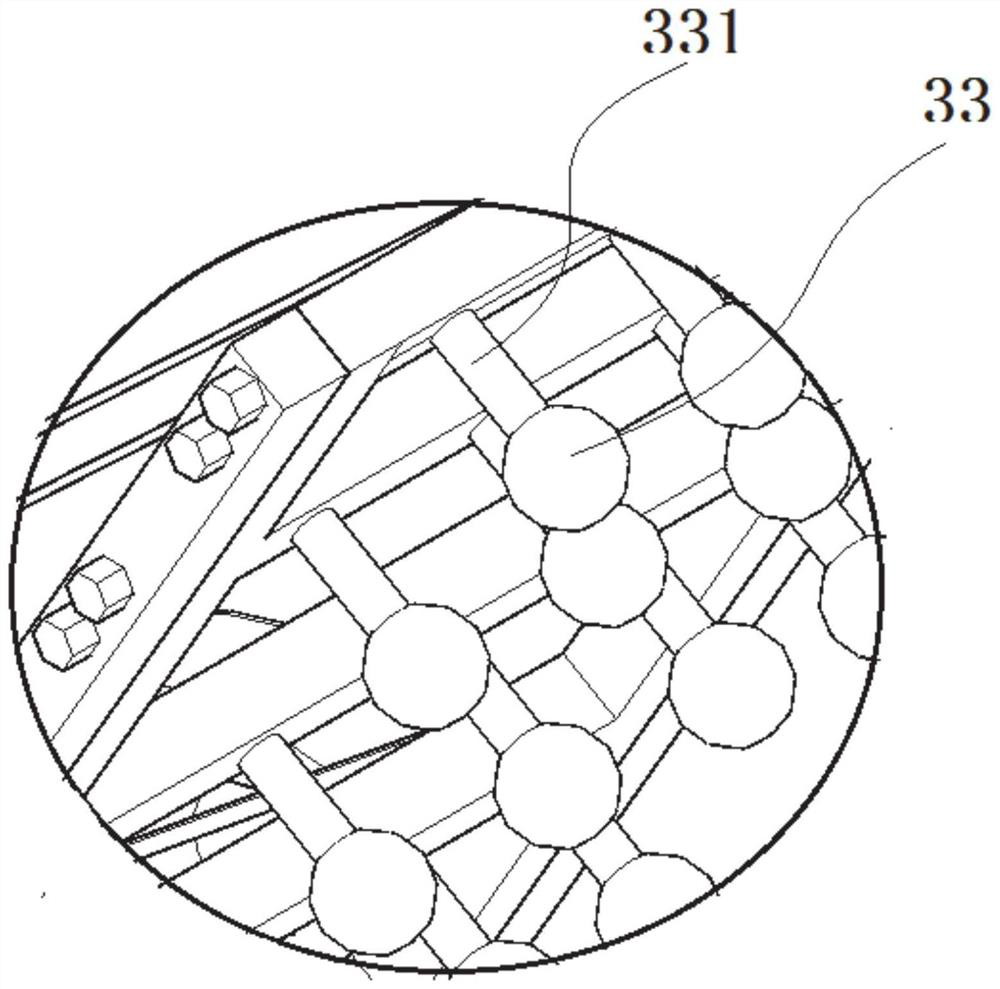

[0050] The front and rear sides of the rectangular mounting frame rod 32 are all inclined downwardly arranged...

Embodiment 2

[0065] Embodiment 2 substation monitoring method

[0066] Such as Figure 1-8 As shown, a substation monitoring device includes monitoring components arranged symmetrically on the left and right sides;

[0067] The monitoring components are connected by telescopic elements 6;

[0068]The monitoring components all include a rectangular rack bar 1, and the front and rear sides of the top of the rectangular rack bar 1 are equipped with suspensions 4 arranged at intervals before and after;

[0069] The suspension 4 includes a horizontal portion 42 assembled on the rectangular frame rod 1, and the left side of the horizontal portion 42 is inclined upwardly provided with an inclined portion 41;

[0070] A monitoring component 3 is installed between the inclined parts 41, and the monitoring part 3 includes a rectangular mounting rod 32 assembled on the inclined part 41;

[0071] The front and rear sides of the rectangular mounting frame rod 32 are all inclined downwardly arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com