Method and apparatus for producing lithium chloride

A technology for preparing a device and lithium chloride, applied in the direction of alkali metal chloride, etc., can solve the problems of complex process, environmental problems of waste residues, labor costs, and high management costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of lithium chloride according to one embodiment of the present invention may include the step of mixing spodumene ore and chlorine gas to perform a chlorination reaction and the step of generating lithium chloride gas through the chlorination reaction and sublimating the gas .

[0032] First, spodumene ore (LiAlSi 2 o 6 ) is mixed with chlorine gas to carry out the step of chlorination reaction.

[0033] The specific reaction is shown in Reaction Formula 1 below.

[0034] [Reaction 1]

[0035] LiAlSi 2 o 6 (s)+1 / 2Cl 2 (g)=LiCl+1 / 4O 2 (g)+1 / 6Al 6 Si 2 o 13 (s)+5 / 3SiO2 2

[0036] Specifically, the lithium element contained in the spodumene ore can be extracted in the form of lithium chloride by performing a chlorination reaction after mixing the spodumene ore and chlorine gas.

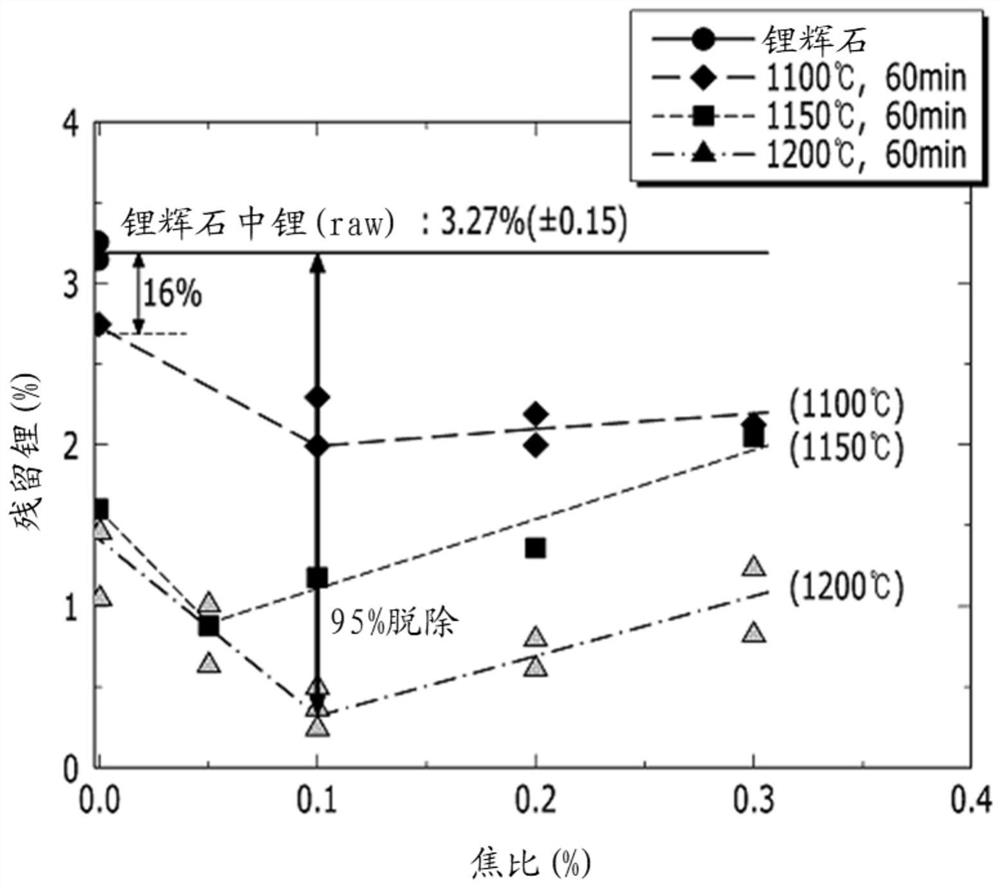

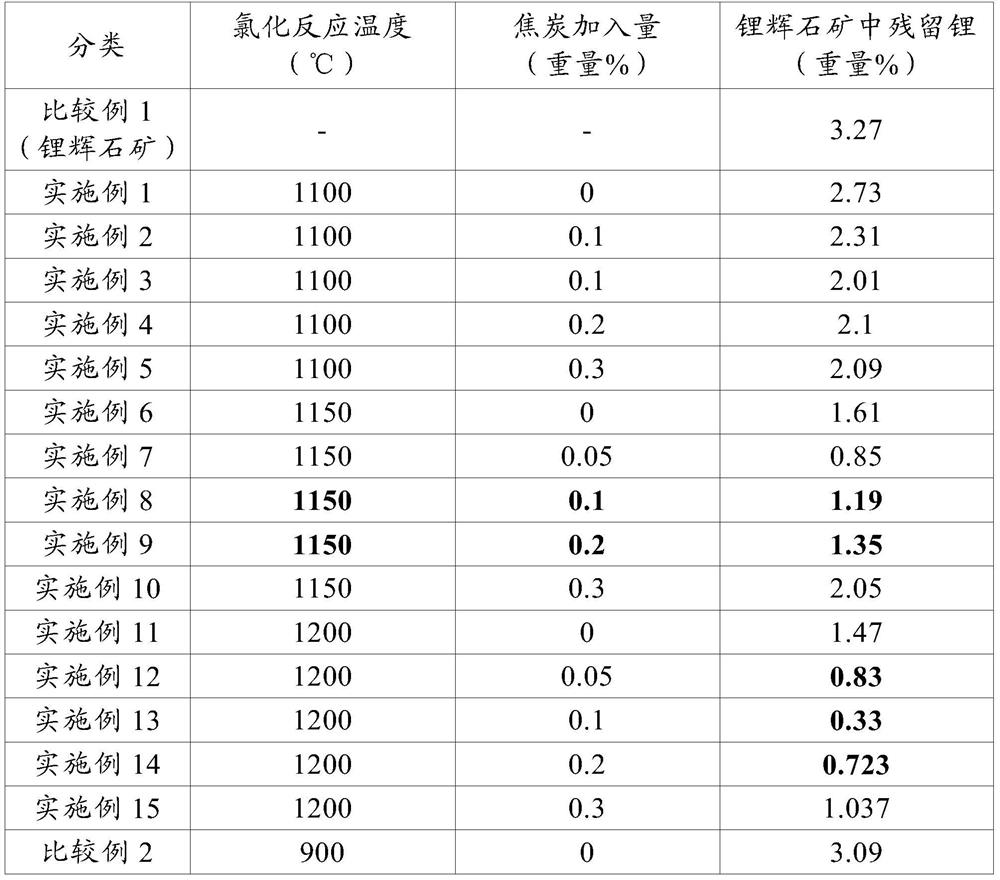

[0037] The chlorination reaction step may be carried out at a temperature range of 1100°C or higher.

[0038] In the temperature range, a reaction such as the ...

Embodiment

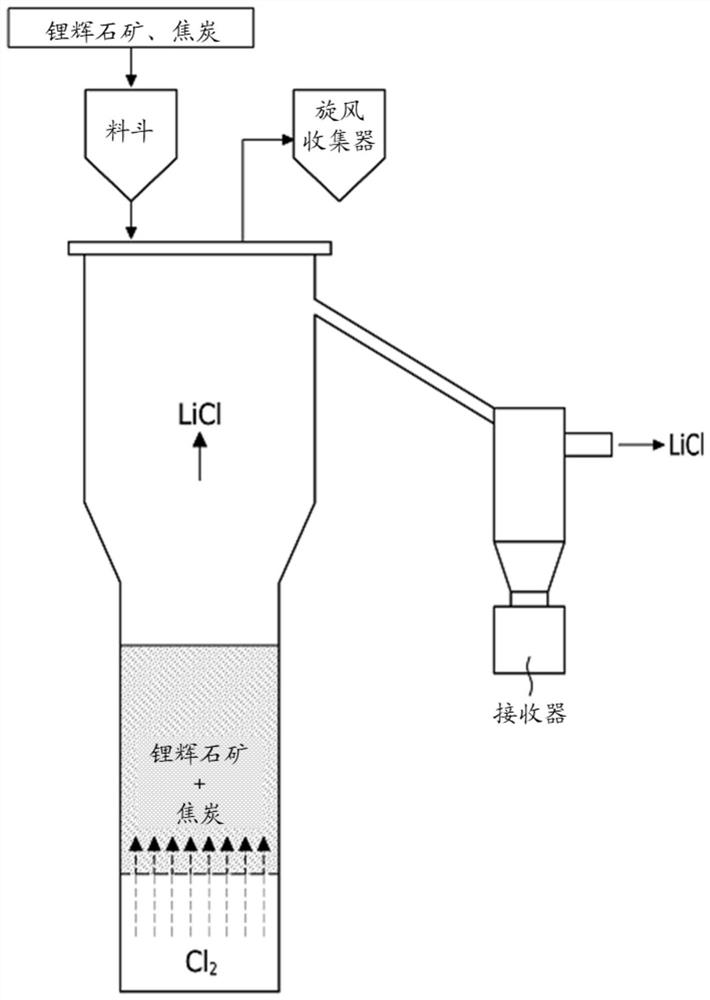

[0085] After spodumene ore and coke are fed into a hopper into a flow chlorinator, chlorine gas is further added to the flow chlorinator to perform a chlorination reaction. At this time, the particle size of ore and coke is maintained in the range of about 100 μm to 400 μm.

[0086] The method of receiving from the hopper is to mix the spodumene ore and coke and inject it into the hopper from the top.

[0087] The flow rate of the chlorine gas is 1000 sccm / min. The internal pressure of the mobile chlorinator is 1 atm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com