Formwork unit and method for constructing concrete structure

A technology for concrete structures and construction methods, applied in building components, building structures, formwork/formwork components, etc., can solve the problems of operation, time, cost increase, easy to fall off, etc., to suppress falling off and collapse, and improve earthquake resistance. , the effect of excellent shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] (frame unit)

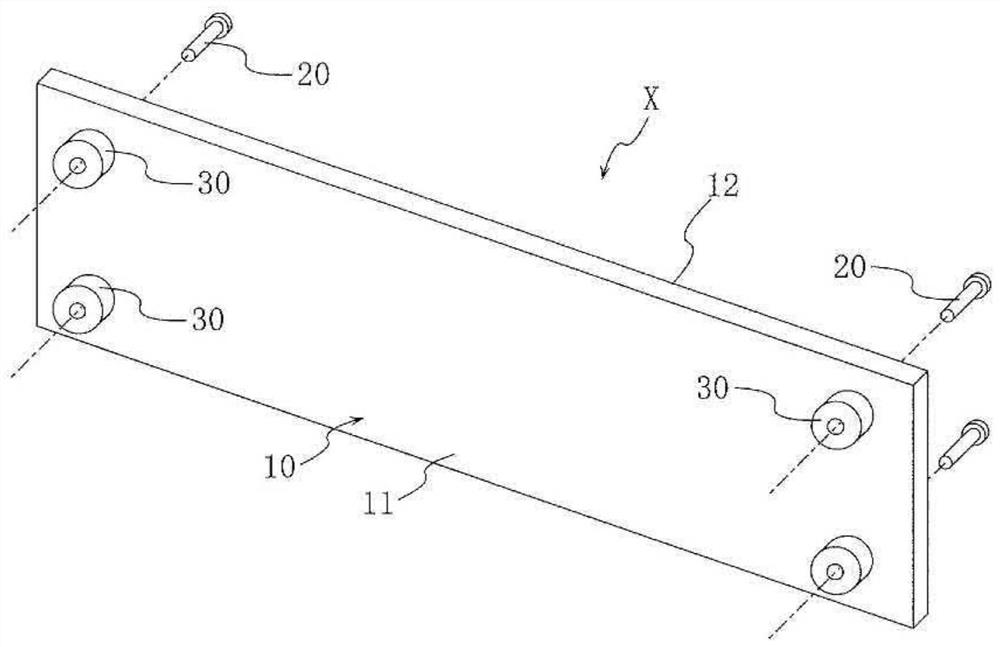

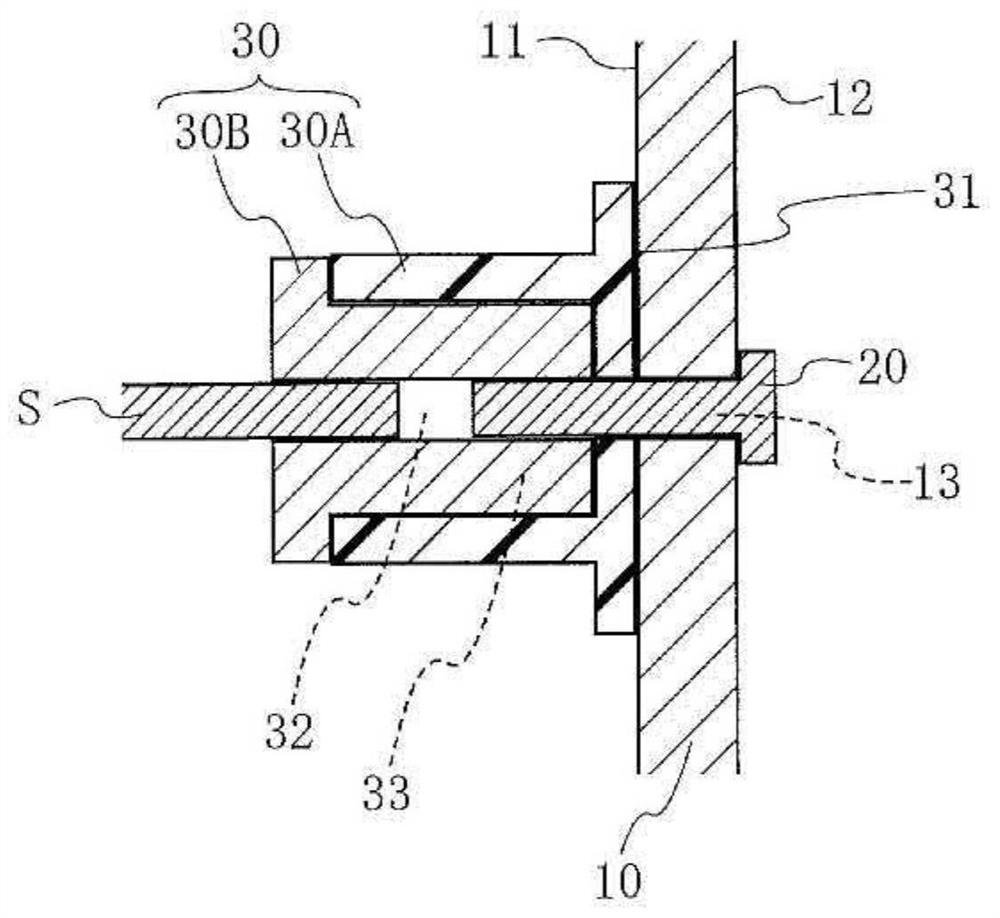

[0074] The frame unit X of the present invention includes at least one embedded plate 10 and at least one fixing piece 30 . The fixture 30 has an end surface 31 for abutting against the embedded panel 10, is a member screwed to the embedded panel 10 on the end surface 31, and can be connected to an assembly position side connecting member. The form unit X of the present invention is used to form a form for pouring concrete.

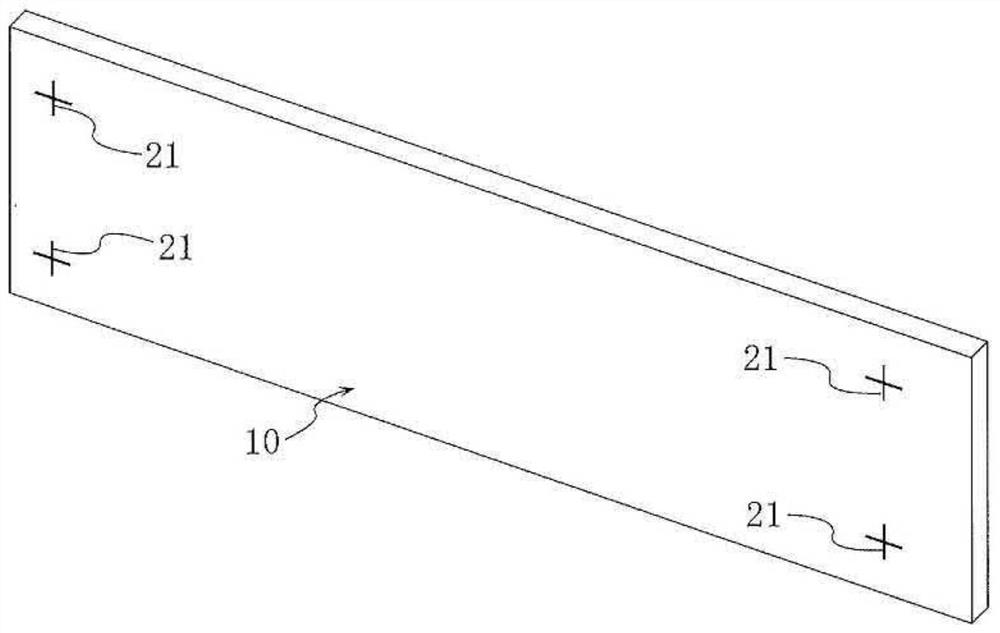

[0075] figure 1 , image 3 A frame unit X according to one embodiment of the present invention is shown. The frame unit X has at least one embedded plate 10 , and each embedded plate 10 has at least one set of fixing parts 30 . The fixing member 30 is screwed to the embedded plate 10 .

[0076] (embedded board)

[0077] The embedding slab 10 of the present invention is a stone slab (= a formwork placed at a position in direct contact with concrete) constituting the shape of a concrete structure, and is not removed after the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com