Rail transportation system for assisting wax gourd planting

A technology for rail transportation and wax gourd, which is applied in transportation and packaging, plant support, manual conveying devices, etc. It can solve the problems of black-skinned wax gourd, such as large volume and weight, low transportation efficiency, and short service life, and achieve installation and segmental disassembly Simple, easy handling and storage, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples.

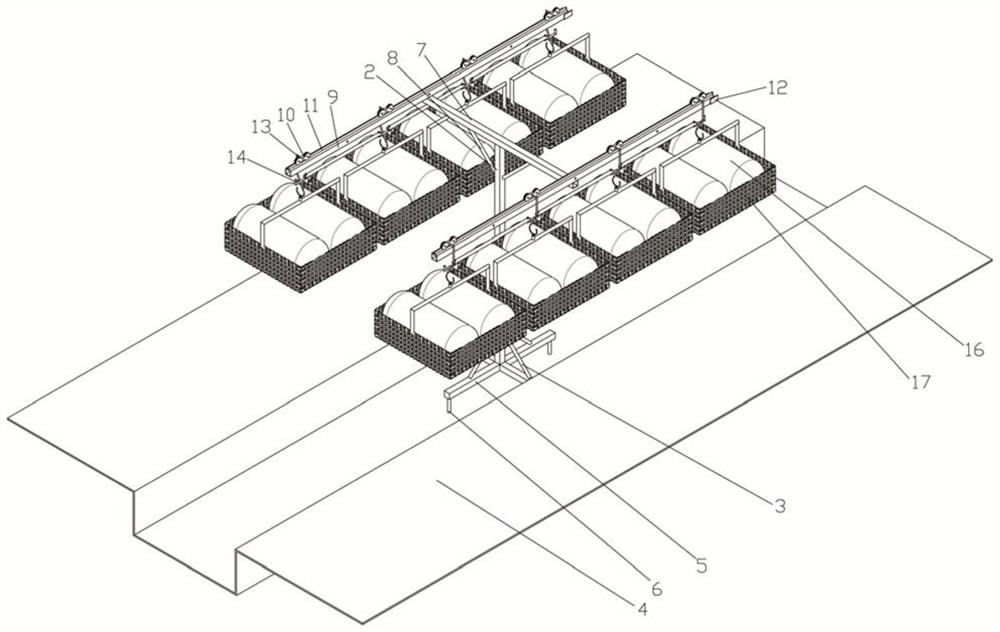

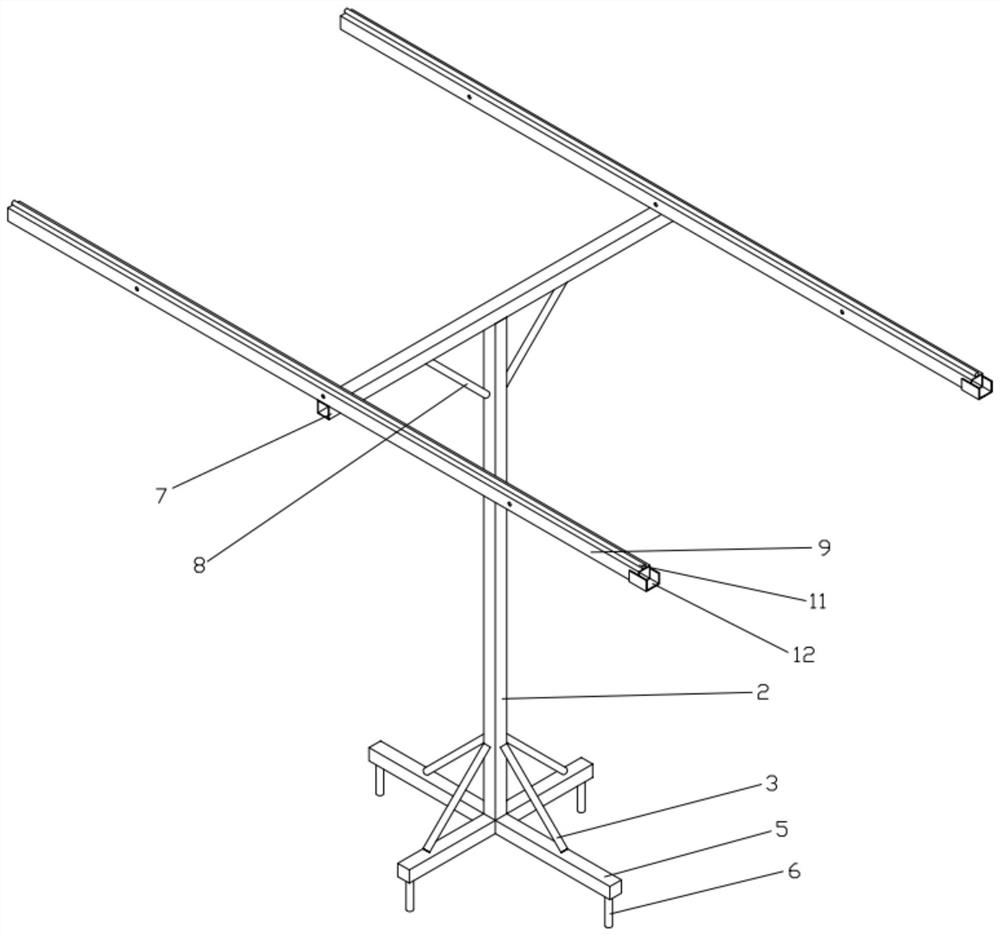

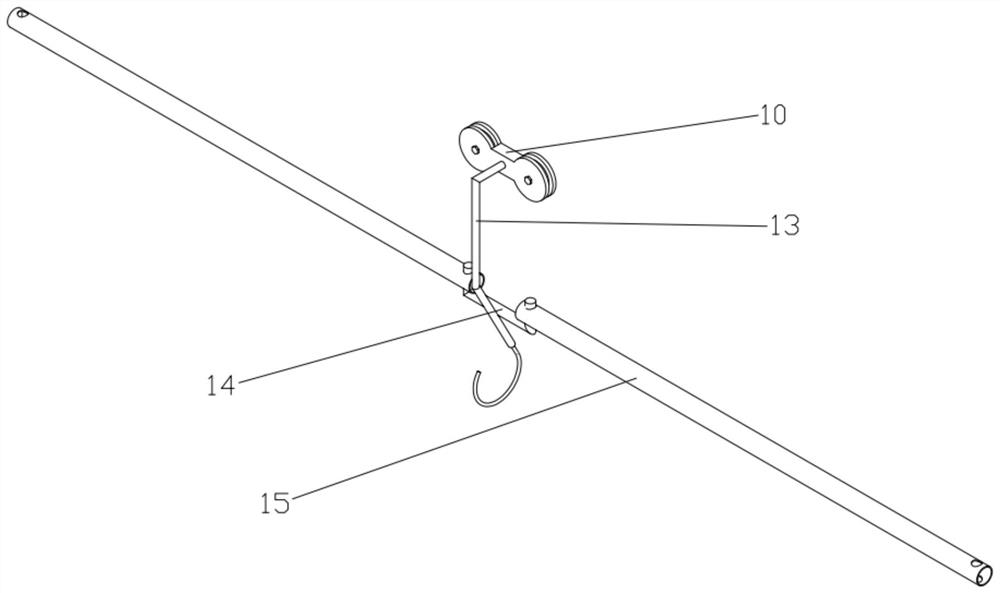

[0018] see Figure 1 to Figure 4 As shown, the rail transport system for auxiliary planting wax gourd provided by this embodiment includes a metal frame, a hooked pulley assembly, a connecting rod 15 and a rattan pole 1; 4 in the middle, and there are several distributed along the length direction of the field ridge 4. The metal frame includes a cross support seat 5 with a fixed foot 6, a support bar 2, a cross bar 7, a wax gourd hanging bar 9 and a guide rail 11. The fixed The feet 6 are distributed on the four end bottom surfaces of the cross support seat 5, and the cross support seat 5 is stabilized by inserting the fixed feet 6 into the soil. The support rod 2 is vertically fixed at the center of the cross support seat 5, that is, the cross support The intersection of the four arms of the seat 5, and between it and each arm of the cross support seat 5 is strengthened and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com