Control method of mosquito killer

A control method and technology for mosquito coils, which are applied to fumigators, devices for capturing or killing insects, applications, etc., can solve problems such as poor thermal conductivity, loss of mosquito repellent, and low central heating, and achieve poor volatile dispersion uniformity, The effect of small loss of mosquito repellent liquid and large mosquito repellent range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

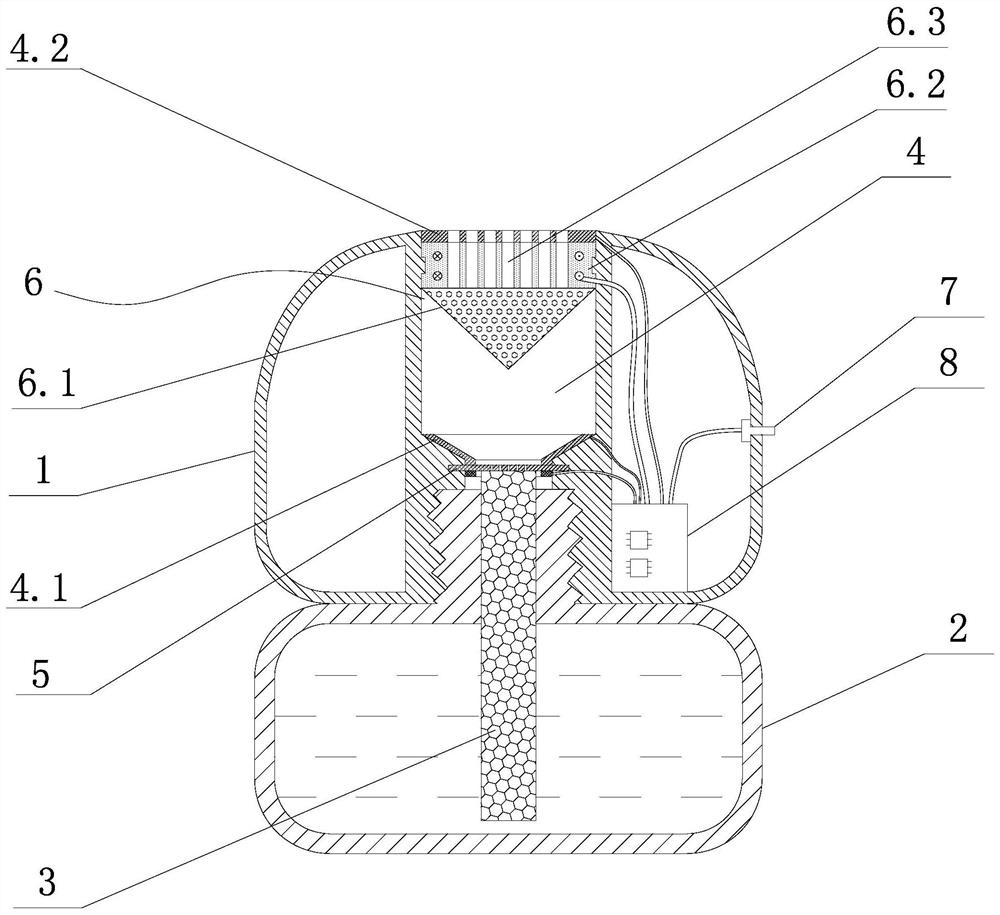

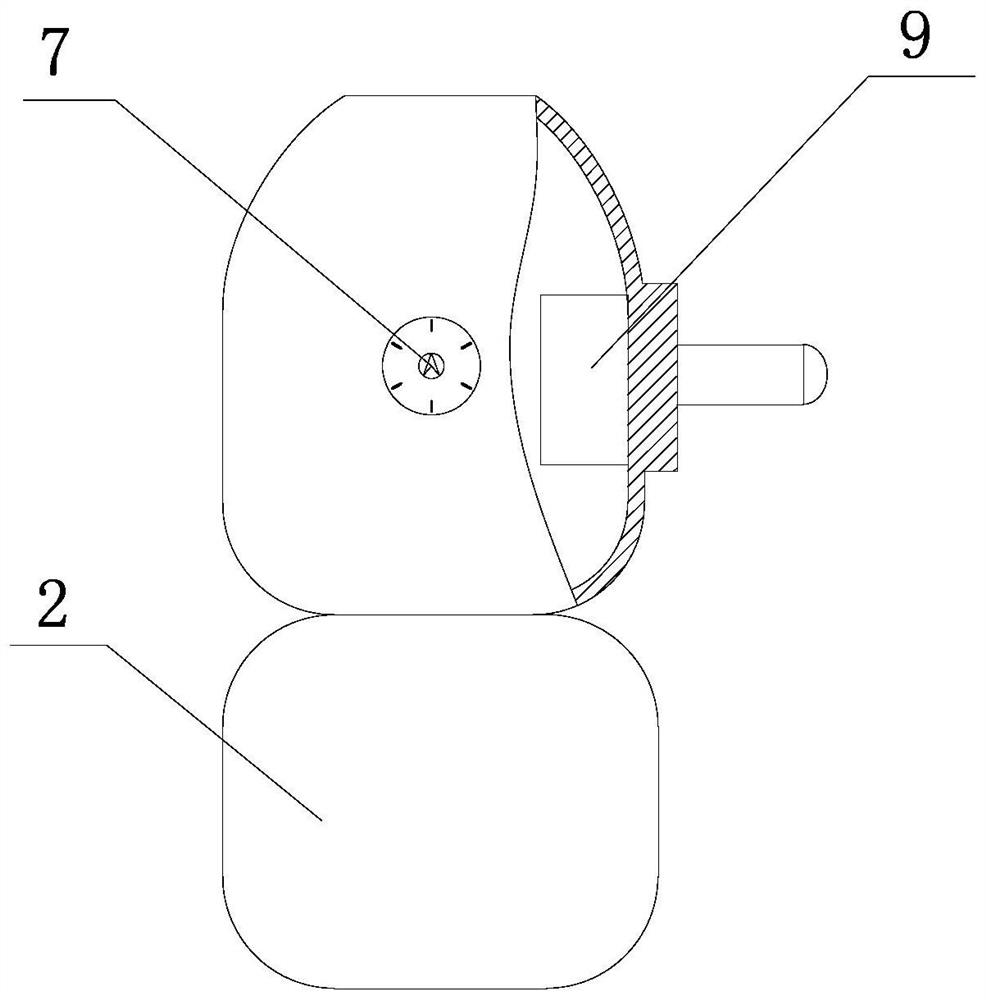

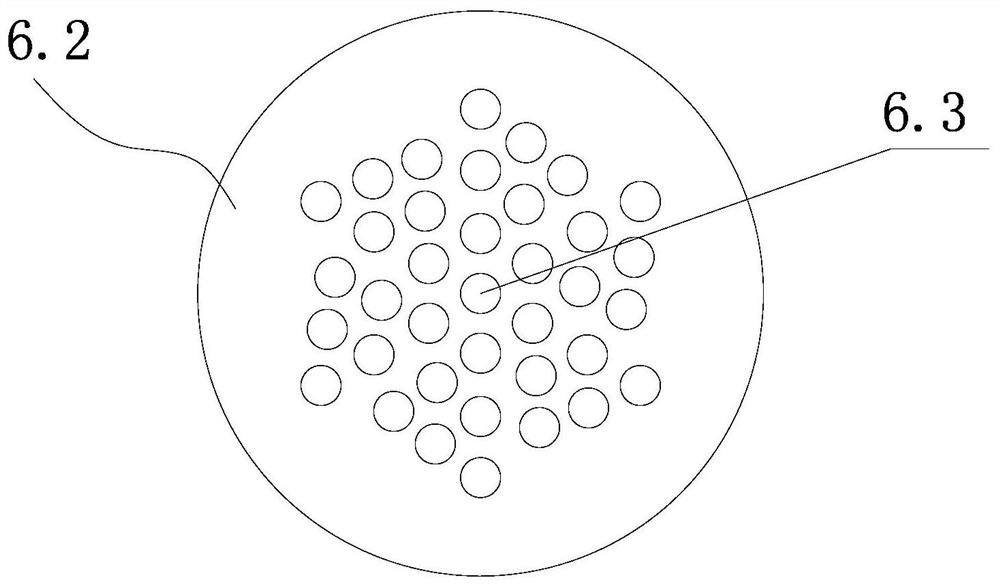

[0019] Such as Figure 1-3 Shown, a kind of control method of mosquito-repellent incense device, this control method is based on following mosquito-repellent device structure, described mosquito-repellent device comprises electric heating head 1, and the mosquito repellent liquid storage tank 2 that is matched with described electric heating head 1 through screw thread; The liquid storage tank 2 is provided with a capillary cotton core 3; the electric heating head 1 is provided with an atomizing chamber 4, and the bottom of the atomizing chamber 4 is provided with an atomizing sheet 5; one end of the capillary cotton core 3 extends into The bottom of the mosquito repellent liquid storage tank 2, the other end protrudes from the top of the mosquito repellent liquid storage tank 2 and contacts the bottom surface of the atomizing sheet 5; the mosquito repellent liquid drawn by the capillary cotton core 3 through the atomization The micropores in the middle of the sheet 5 penetrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com