Production device suitable for heparin anticoagulant tubes and process thereof

A technology for producing a device and an anticoagulation tube, which is applied in the field of heparin anticoagulation tube production, can solve the problems of inconvenient removal of the test tube, uneven heat damage of the tube wall, etc., and achieves the effects of improving production efficiency and being easy to pick and place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

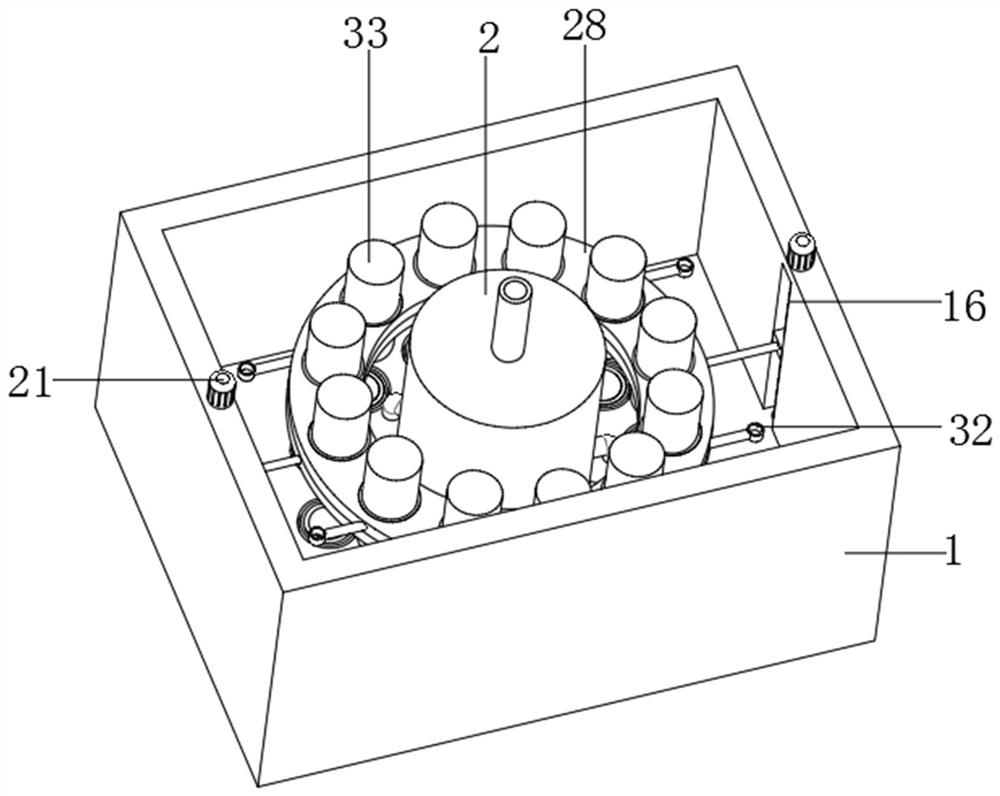

[0036] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides the following technical solutions:

[0037] A production device suitable for heparin anticoagulation tubes, including an attachment box 1 and a test tube 33, a heparin liquid cylinder 2 is installed at the center of the bottom end of the inner cavity of the attachment box 1, and the height of the heparin liquid cylinder 2 is smaller than the depth of the inner cavity of the attachment box 1 ;

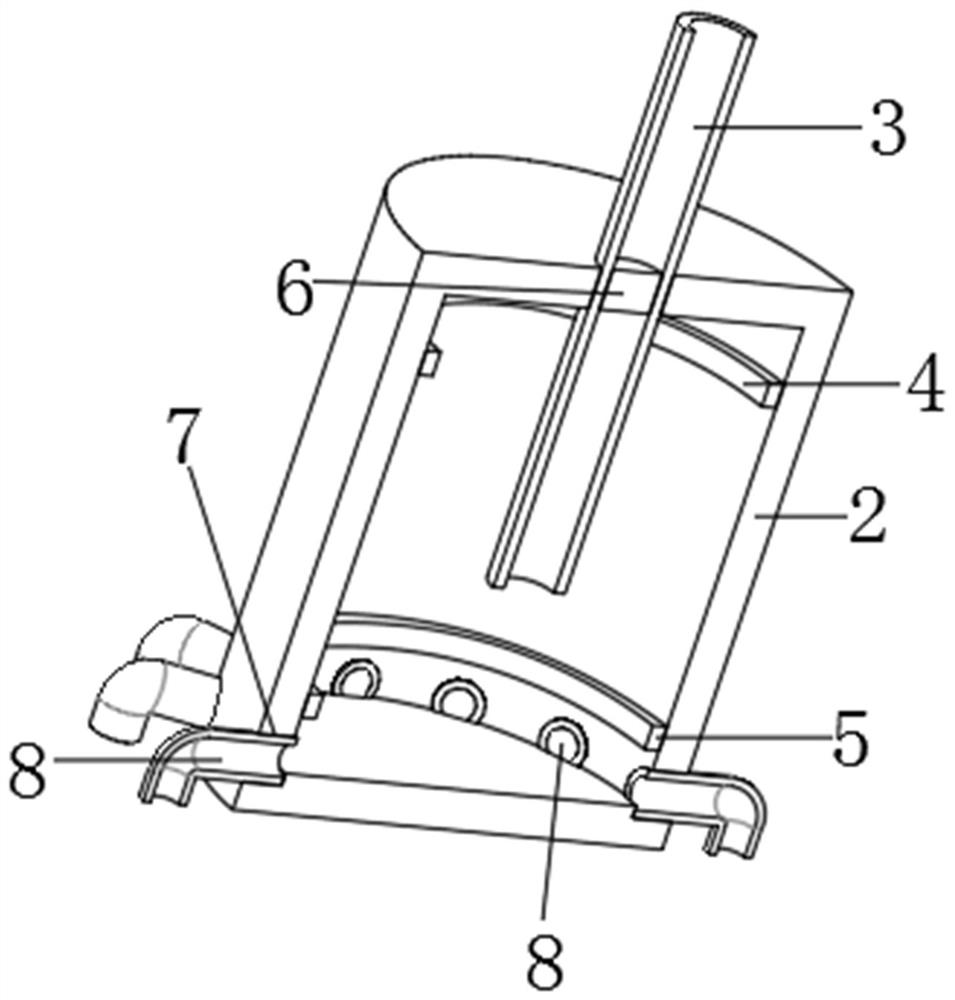

[0038] Among them, such as figure 2 As shown, the heparin liquid cartridge 2 is provided with a fluid replacement component inside, and the fluid replacement component includes a fluid replacement tube 3 , an upper liquid level sensing ring 4 , a lower liquid level sensing ring 5 and a solenoid valve 6 ;

[0039] Specifically, the fluid replacement tube 3 runs through the center of the top of the heparin solution cylinder 2, and the bottom of the fluid replacement tube 3 is lower than...

Embodiment 2

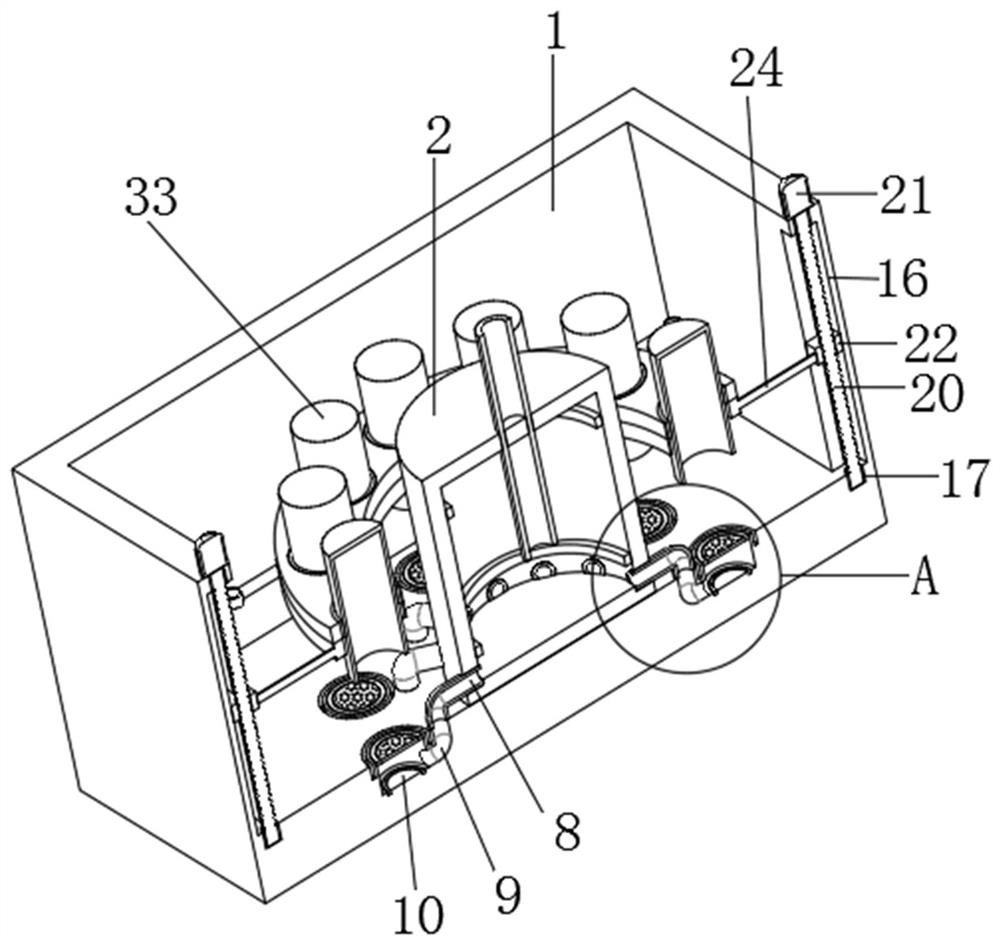

[0048] On the basis of Example 1, refer to figure 1 , image 3 , Figure 5 and Image 6 As shown, a production device suitable for heparin anticoagulation tubes:

[0049] Among them, such as image 3 and Figure 5 As shown, a transmission assembly is arranged on the inner wall of the attachment box 1;

[0050] Specifically, the transmission assembly includes a chute 16, a mounting hole 17, a lower bearing 18, an upper bearing 19, a screw 20, a servo motor 21, a slider 22, and a through screw hole 23. The chute 16 has two groups and is arranged in the attachment box. 1 On the opposite inner wall where the width direction of the inner wall is located, the mounting hole 17 is set at the center of the bottom and top of the chute 16 and the upper mounting hole 17 is set through the top of the attachment box 1, and the lower bearing 18 and the upper bearing 19 are installed in the mounting hole 17, The screw 20 rotates in the chute 16 through the lower bearing 18 and the upper...

Embodiment 3

[0058] On the basis of Example 2, refer to figure 1 and figure 2 As shown, a production device suitable for heparin anticoagulation tubes:

[0059] It should be noted that the end of the liquid outlet tube 8 located in the heparin solution cartridge 2 is flush with the liquid outlet 7, the diameter of the flow channel 9 is smaller than the outer diameter of the end of the liquid outlet tube 8, and the diameter of the flow channel 9 is larger than that of the liquid outlet. The inner diameter of the end of the tube 8, the horizontal plane at the bottom of the flow channel 9 and the horizontal plane at the bottom of the liquid storage tank 10 are the same horizontal plane, and the volume capacity in the liquid storage tank 10 and the volume capacity of the test tube 33 are in a ratio of one to ten; The bottom end of the chute 16 is flush with the bottom end of the inner cavity of the attachment box 1, the height of the chute 16 is less than the depth of the inner cavity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com