A Method for Acquiring Transmission Torque of Strip Mill

A technology of transmission torque and acquisition method, which is applied to the driving device of metal rolling mill, rolling mill control device, metal rolling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] For a better understanding of the present invention, the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

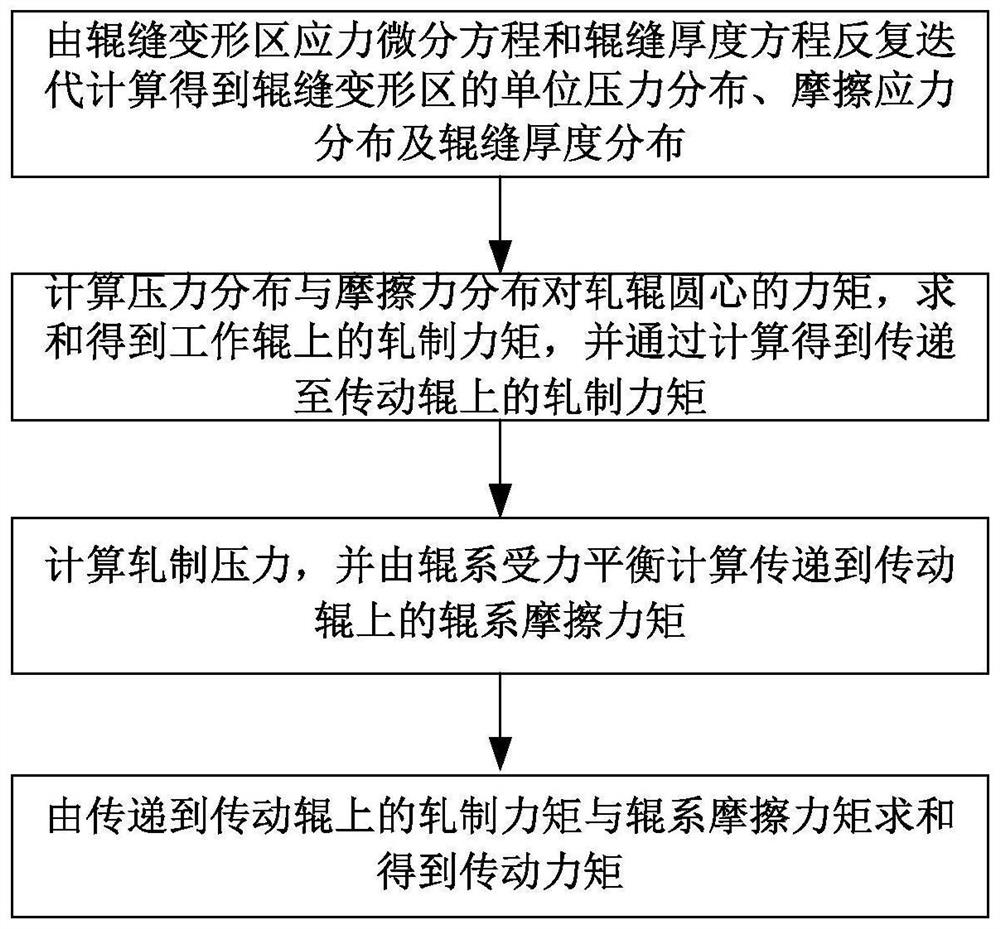

[0028] like figure 1 The shown method for obtaining the transmission torque of a strip rolling mill specifically includes the following steps:

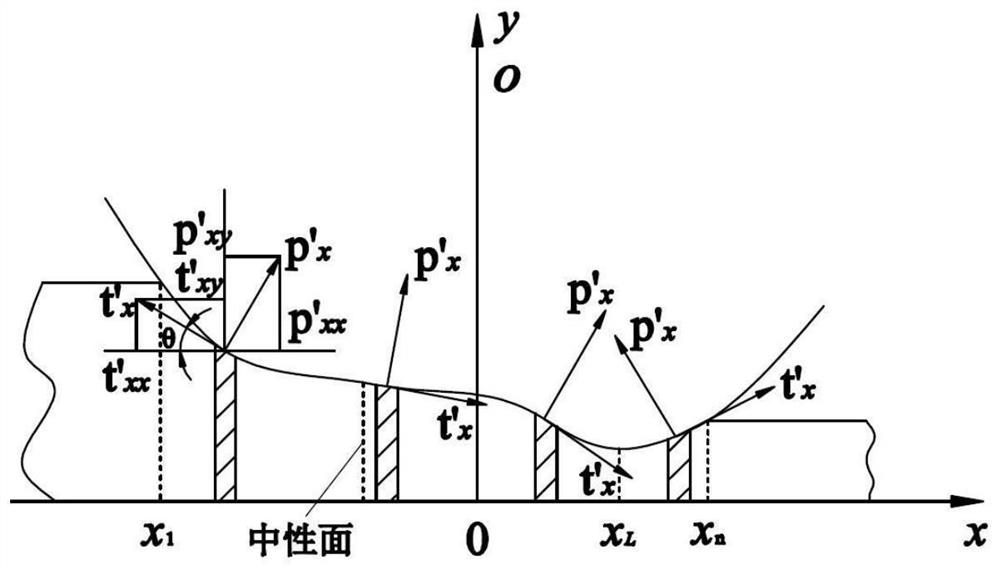

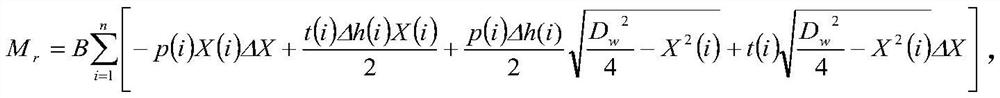

[0029] Step 1: Iteratively iterate the stress differential equation of the roll gap deformation zone and the roll gap thickness equation, and calculate the unit pressure distribution, friction stress distribution and roll gap thickness distribution of the roll gap deformation zone.

[0030] Since there are many iterative calculation methods for the stress differential equation of the roll gap deformation zone and the roll gap thickness equation (which are technologies disclosed in the industry), only one of the calculation methods is provided here, specifically:

[0031] S101 , setting an initial roll profile curve, and determining an entrance positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com