Solidification microstructure refinement method of steel continuous casting slab based on target equiaxed grain size and proportion

A technology of solidification structure and equiaxed crystals, which is applied in the field of iron and steel metallurgy, can solve the problems of homogeneity and density affecting the quality stability of high-end steel products, solute segregation, and severe anisotropy, so as to improve processing performance and service performance. Improve the effect of homogeneity and density, theory and process improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

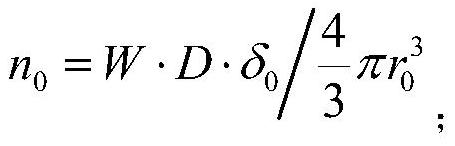

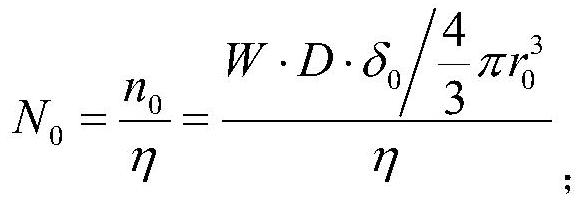

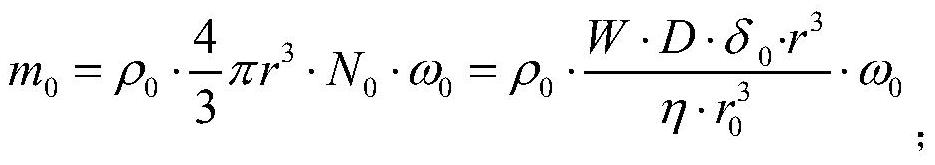

Method used

Image

Examples

Embodiment 1

[0075] According to the quality requirements, the target equiaxed grain size is set to 100 μm, and the area ratio of the equiaxed grain area is 36%. According to the calculation and solution of the aforementioned method, the total amount of zirconium-iron alloy that needs to be added to VD in the 100t ladle is 2.67Kg; when a gear steel After entering the VD, add 2.67Kg bulk zirconium-iron alloy, and use gas to stir until uniform; then lift the molten steel with qualified composition and temperature to the continuous casting ladle turret, and then use the same parameters as the comparative example to complete the casting and solidification. The cross-section of the slab sample was treated by a grinding machine and then etched with hot hydrochloric acid solution or electrolyte. It can be observed that the area ratio of equiaxed crystals is about 36%, and the diameter of equiaxed crystals is about 100 μm.

Embodiment 2

[0077] According to the quality requirements, the target equiaxed grain size is set to 150 μm, and the area ratio of the equiaxed grain area is 64%. According to the above method, VD+tundish double-point addition can be carried out, and the total amount of ferro-titanium alloy added to VD in the 100t ladle is calculated as 1.62Kg, the feed rate of titanium iron in the tundish is 12m / min, when a certain boiler tube steel enters the VD, add 1.62Kg bulk zirconium ferroalloy, and use gas to stir until uniform; then lift the molten steel with qualified composition and temperature To the continuous casting ladle turret, after the molten steel enters the tundish, start to feed the line at the above rate, and then use the parameters consistent with the comparative example to complete casting and solidification. The cross-section of the slab sample was treated by a grinding machine and then eroded by hot hydrochloric acid solution or electrolyte. It can be observed that the area ratio o...

Embodiment 3

[0079] According to the quality requirements, the target equiaxed crystal size is set to 120 μm, and the area ratio of the equiaxed crystal region is 50%. According to the aforementioned method, the tundish + mold double-point feeding line can be carried out, and the calculated line rate of feeding titanium iron in the tundish is: 10m / min, the crystallizer feeding cerium iron line speed is 5m / min. A certain Q345E molten steel with qualified composition and temperature after refining is hoisted to the turret of continuous casting ladle. After the molten steel enters the tundish, it starts to feed the ferro-titanium wire at the above rate, and after pouring into the crystallizer, feeds the ferro-cerium wire at the above rate. Casting and solidification were then performed using parameters consistent with those of the comparative example. The cross-section of the cast slab sample was treated by a grinding machine and then etched with hot hydrochloric acid solution or electrolyte....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com