A drill press capable of automatic cleaning and chip removal

An automatic cleaning and drilling machine technology, which is applied in the field of drilling machines, can solve the problems of consuming a lot of human resources, troublesome cleaning, and accumulation of waste debris, etc., so as to avoid machine wear and increase in use costs, and is conducive to long-term work and high-efficiency of the machine The effect of efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

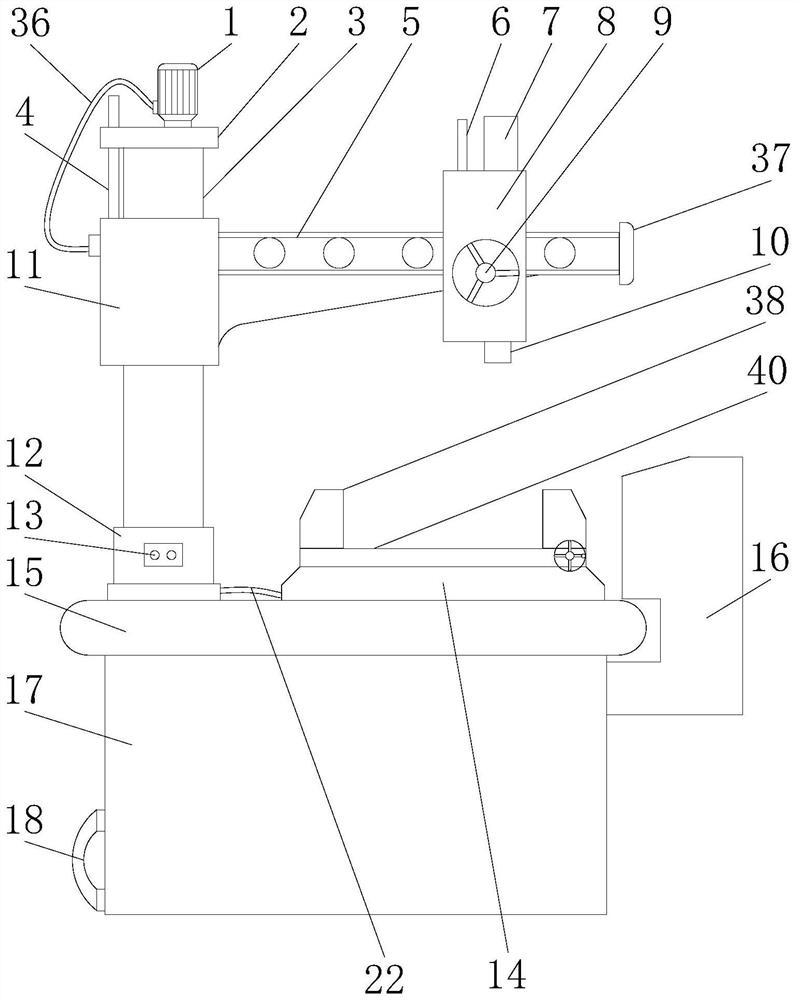

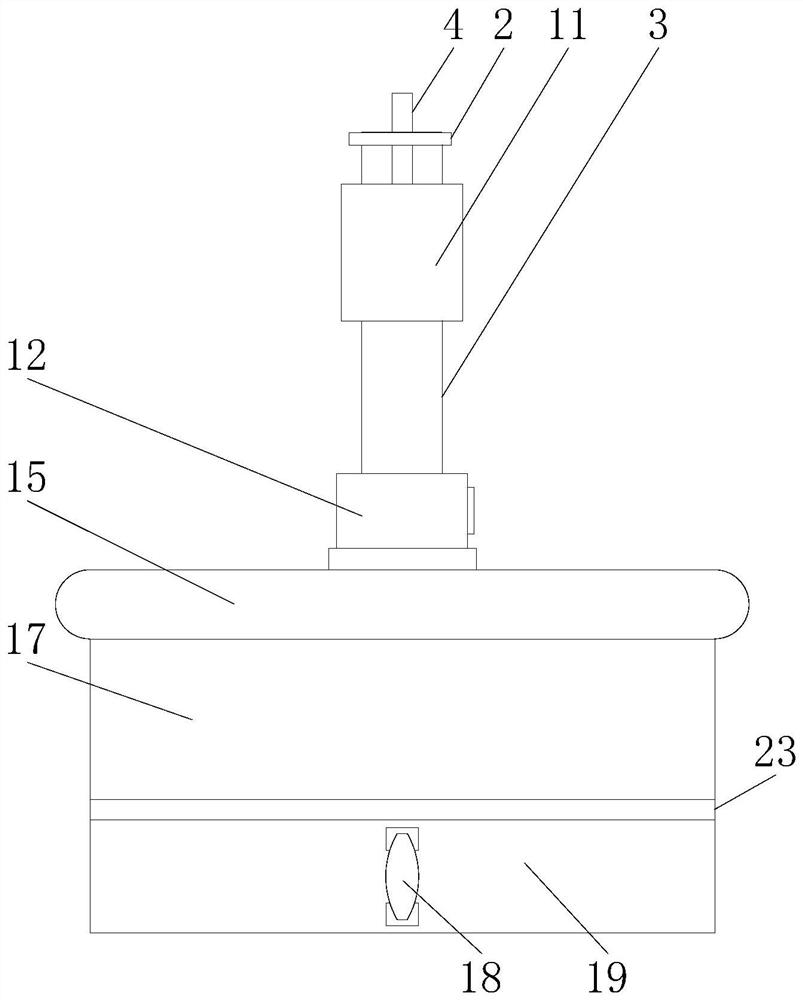

[0031] Such as Figure 1-Figure 6 As shown, the present invention provides a drilling machine capable of automatic cleaning and chip removal. The heat dissipation chamber 15 has a condenser 33 fixedly installed on the inner bottom of the heat dissipation chamber 15, and a compressor 34 is fixedly installed on the front of the condenser 33. The condenser 33 Condenser tubes 32 are evenly and fixedly connected to both sides of the heat sink 15, and the bottom of the heat dissipation chamber 15 is fixedly equipped with a chip box 17, and the inner top of the chip box 17 is fixedly installed with a hanger 25, and the bottom of the hanger 25 is fixedly installed with a turbine 26, and the turbine The bottom of 26 is movably equipped with rotating shaft 27, and the outer wall of rotating shaft 27 is evenly provided with dust suction fan 28.

[0032] In this embodiment, a condenser 33, a compressor 34 and a plurality of condensation pipes 32 are provided inside the cooling chamber 15 ...

Embodiment 2

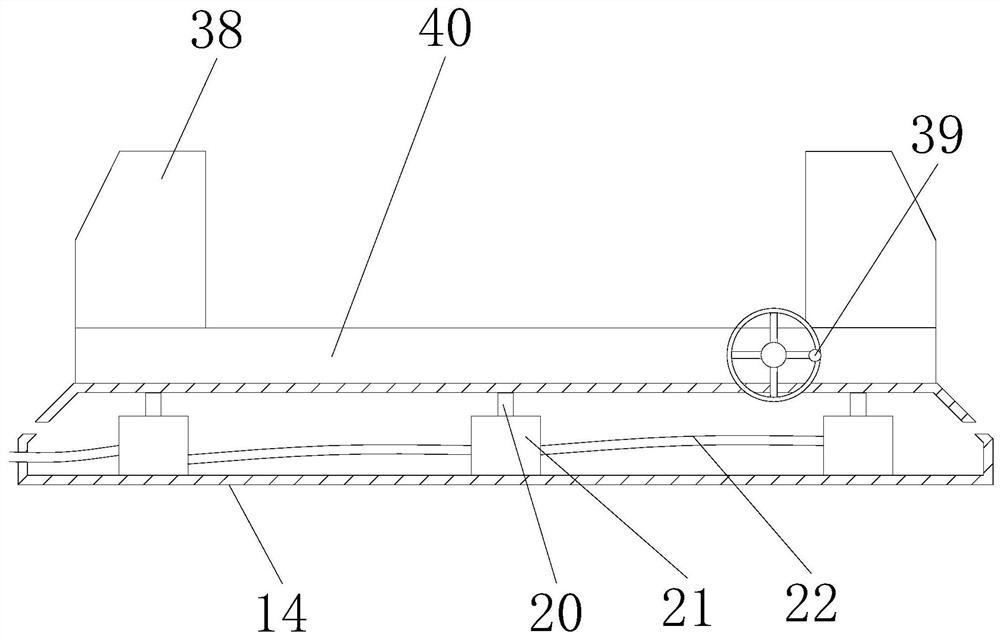

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a support plate 14 is fixedly installed on the top of the cooling chamber 15, which mainly acts on the support fixture 38, and the inner top of the support plate 14 is fixedly installed There is a beam 20, which is mainly used for supporting and weighing. The bottom of the beam 20 is fixed with a scale base 21, which is mainly used for weighing and inductive transmission. The outer wall of the scale base 21 is fixedly connected with a transmission line 22, which is mainly used for transmission. , the transmission line 22 extends to the left and is fixedly connected with the controller 12, which is mainly used to control the vacuuming of the dust collection fan 28. The surface of the cooling chamber 15 is penetrated with a control line 24, and the top of the control line 24 is fixedly connected with the controller ...

Embodiment 3

[0038] Such as figure 1 , figure 2 , Figure 4 , Figure 5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the bottom of the inner side of the dust collection box 17 is provided with a slideway-31, which is mainly used to facilitate sliding, and the top of the slideway-31 A pulley 30 is provided, which is mainly used to facilitate sliding. The top of the pulley 30 is fixed with a drawer 19, which is mainly used for loading waste and can be replaced quickly. The left side of the drawer 19 is fixed with a handle 18, which is mainly used for pulling. Drawer 19, the top left side of drawer 19 is provided with sealing strip 23, and it is mainly used in sealing, and the top of cooling bin 15 is fixedly installed with controller 12, and the front of controller 12 is fixedly installed with control button 13, and it mainly acts on control. To operate the machine, the right side of the controller 12 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com