Steel block cutting and polishing device for manufacturing high-end equipment

A technology of equipment and steel blocks, which is applied in the field of steel block segmentation and polishing equipment for high-end equipment manufacturing, can solve problems such as low efficiency and inability to guarantee the cutting effect of steel blocks, and achieve the effect of improving work efficiency and ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

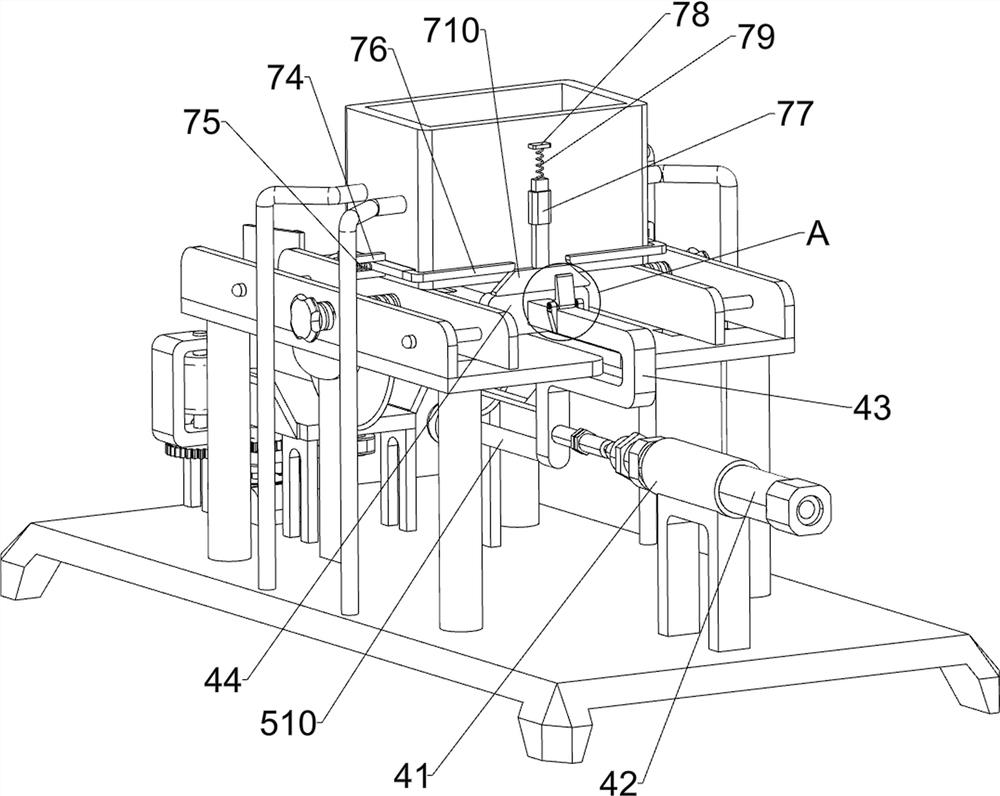

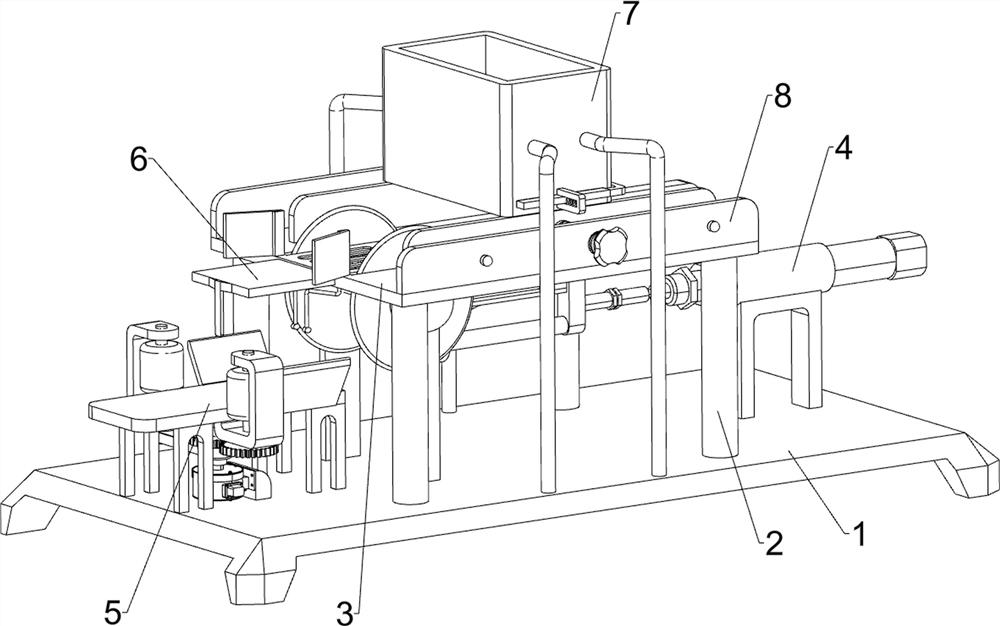

[0028] A high-end equipment manufacturing steel block split polishing equipment, such as Figure 1 to Figure 4 As shown, it includes a base 1, a support column 2, a cutting assembly 3, a propulsion mechanism 4 and a grinding mechanism 5, a support column 2 is installed on the top of the base 1, a cutting assembly 3 is installed between the support column 2 and the base 1, and a cutting assembly 3 is installed on the top of the base 1. Propelling mechanism 4 is installed on the right side, and grinding mechanism 5 is installed on the left side of base 1 top.

[0029] The cutting assembly 3 includes a workbench 31, a fixed mount 32, a cutting machine 33 and a waste partition 34. The top of the support column 2 is connected with a workbench 31, and the front and rear sides in the middle of the top of the base 1 are connected with a fixed mount 32. Cutting machine 33 is all installed on the fixed mount 32 of side, and the saw blade of cutting machine 33 penetrates workbench 31 top...

Embodiment 2

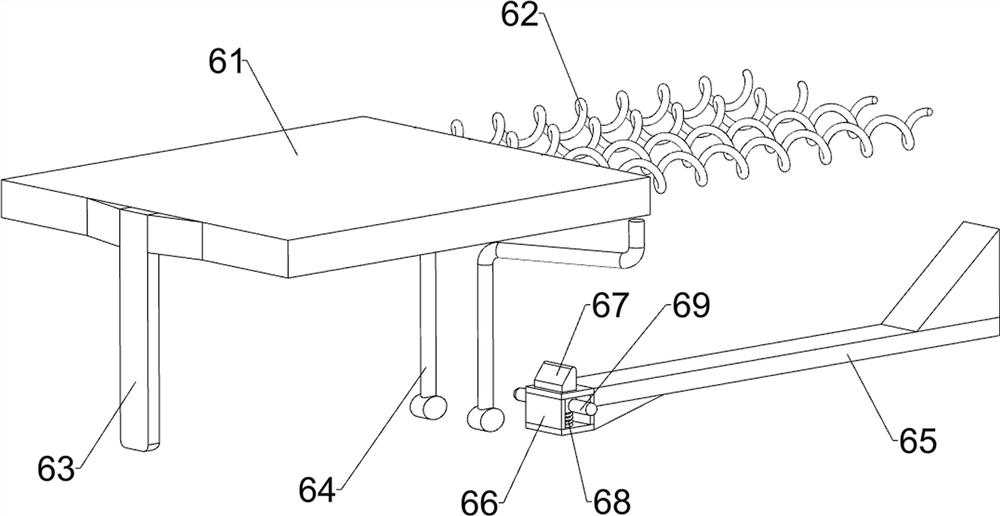

[0034] On the basis of Example 1, such as Figure 5As shown, a movable pallet mechanism 6 is also included, and the movable pallet mechanism 6 includes a sliding pallet 61, a first return spring 62, a fixed pull plate 63, a top block frame 64, a connecting rod 65, a first guide sleeve 66, Block 67, the second back-moving spring 68 and protruding rod 69, the left end of workbench 31 has chute, is connected with sliding supporting plate 61 slidingly in the chute, is connected with the second between sliding supporting plate 61 and the chute inwall. One back-moving spring 62, the left end bottom of sliding supporting plate 61 is connected with fixed pull plate 63, and the left side bottom of workbench 31 is connected with two jacking frame 64, and two jacking frame 64 are symmetrically arranged front and back, special-shaped connecting rod 43 The middle part of the left end of the connecting rod 65 is fixedly connected with the connecting rod 65, and the left end of the connectin...

Embodiment 3

[0037] On the basis of Example 2, such as figure 2 , image 3 and Figure 6 As shown, also includes material storage mechanism 7, and material storage mechanism 7 includes support frame 71, material storage box 72, sliding partition 73, guide block 74, the 3rd return spring 75, ejector rod 76, the second guide sleeve 77 , fixed block 78, the 4th back-moving spring 79, wedge-shaped block frame 710, connecting block 711, scroll spring 712 and L-shaped wedge-shaped block 713, the front and rear both sides in the middle of base 1 top are all connected with support frame 71, the support of both sides The storage box 72 is connected between the top of the frame 71, and the front and rear sides of the bottom of the storage box 72 are slidably connected with a sliding partition 73, and the front and rear sides of the bottom of the storage box 72 are connected with a guide block 74. 74 and the sliding partition 73 are connected with a third return spring 75, the right side of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com