Lifting system applied to lifting and mounting of main tower steel truss

A lifting system and steel truss technology, applied in safety devices, bridge erection/assembly, transportation and packaging, etc., can solve the problems of bulky main tower steel truss, damage to the stability of the bridge main body, low efficiency, etc., to ensure construction efficiency and personal safety, improve the matching accuracy and load performance, and improve the effect of motion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

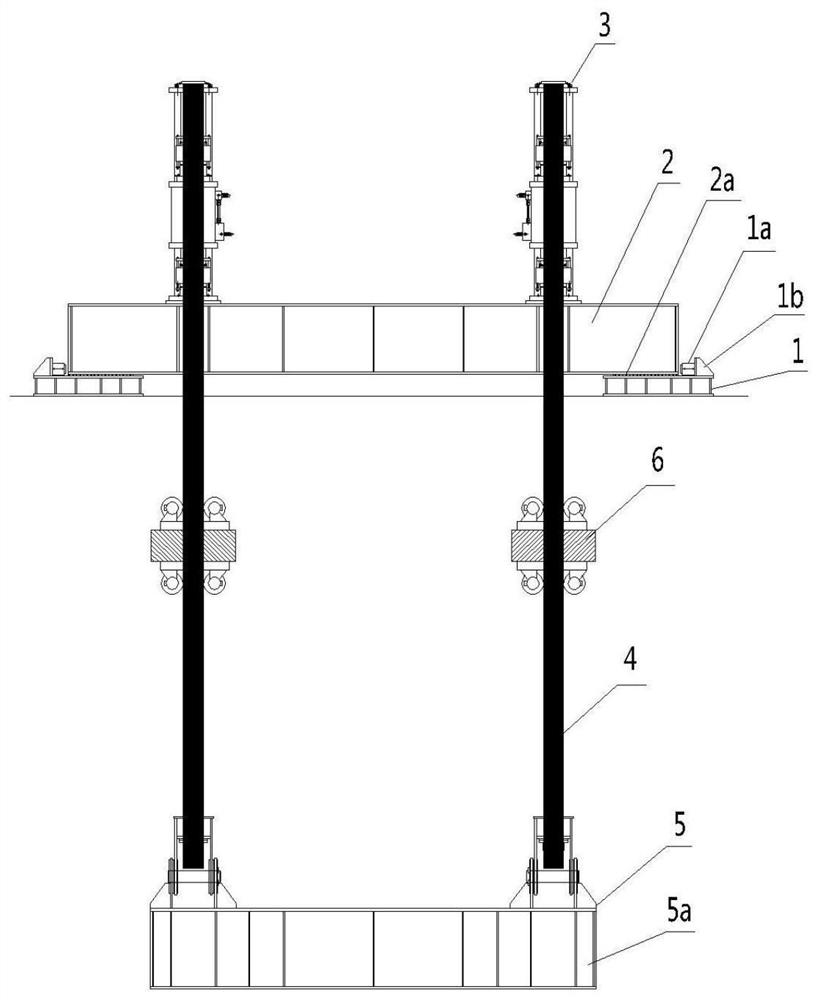

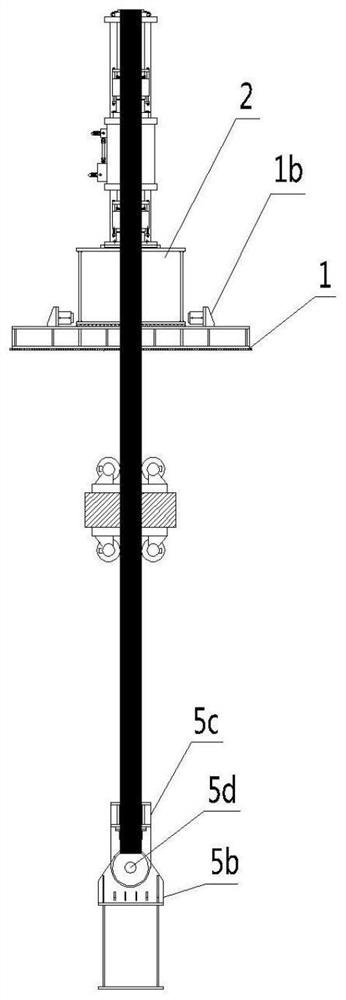

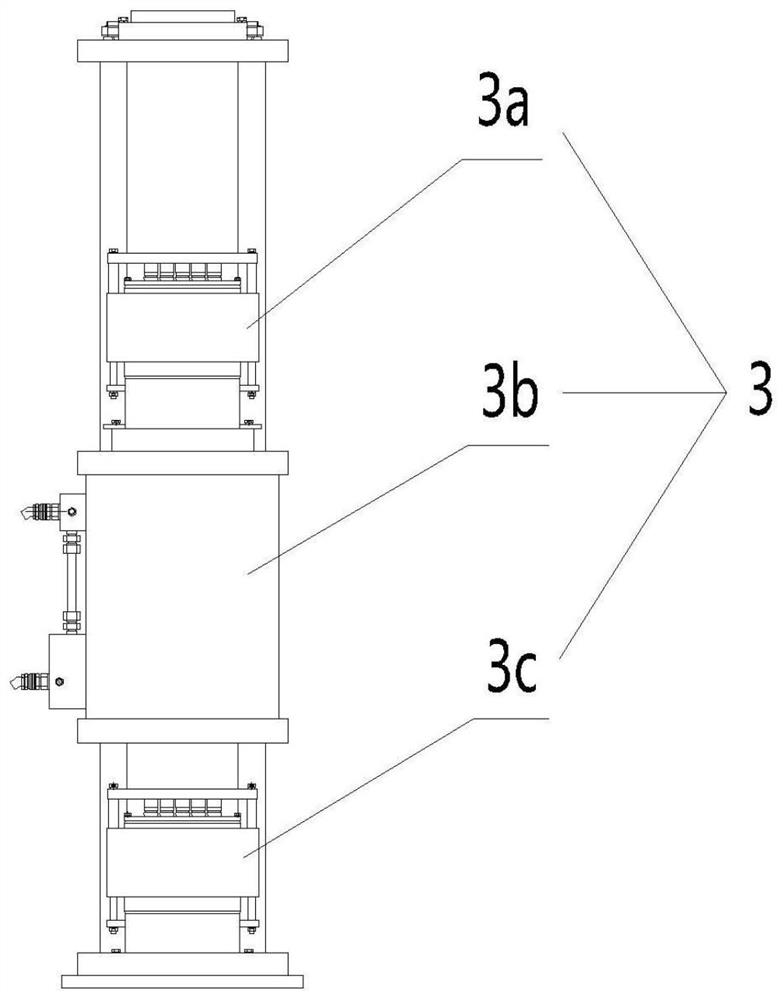

[0030] Such as Figure 1-5As shown, a lifting system applied to the lifting and installation of the main tower steel truss, including two pad beams 1, main longitudinal beams 2, two through-hole jacks 3, two steel strands 4, spreaders 5, two Vibration absorbing mechanism6. Wherein, the two pad beams 1 are respectively arranged in the front and rear end areas of the top surface of the concrete main tower in a symmetrical manner. A lubricating plate 2a made of polytetrafluoroethylene is provided at the bonding parts, so that the main longitudinal girder 2 can fit the lubricating plate 2a to move in the horizontal direction; the upper end surface of the pad beam 1 is provided with a plurality of longitudinal movement jacks 1a, a plurality of transverse movement jacks 1b, a plurality of reaction force seats 1c, the fuselages of a plurality of sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com