Concrete applied to large-volume radiation-proof building and construction process thereof

A construction technology and concrete technology, applied in the processing of building materials, construction, building components, etc., can solve the problems of concrete temperature cracks and shrinkage cracks, the radiation protection effect of the radiation-proof wall is deteriorated, and the temperature difference between the inside and outside of the concrete is large. The effect of reducing adiabatic temperature rise, delaying exothermic effect, and uniform hydration exothermic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

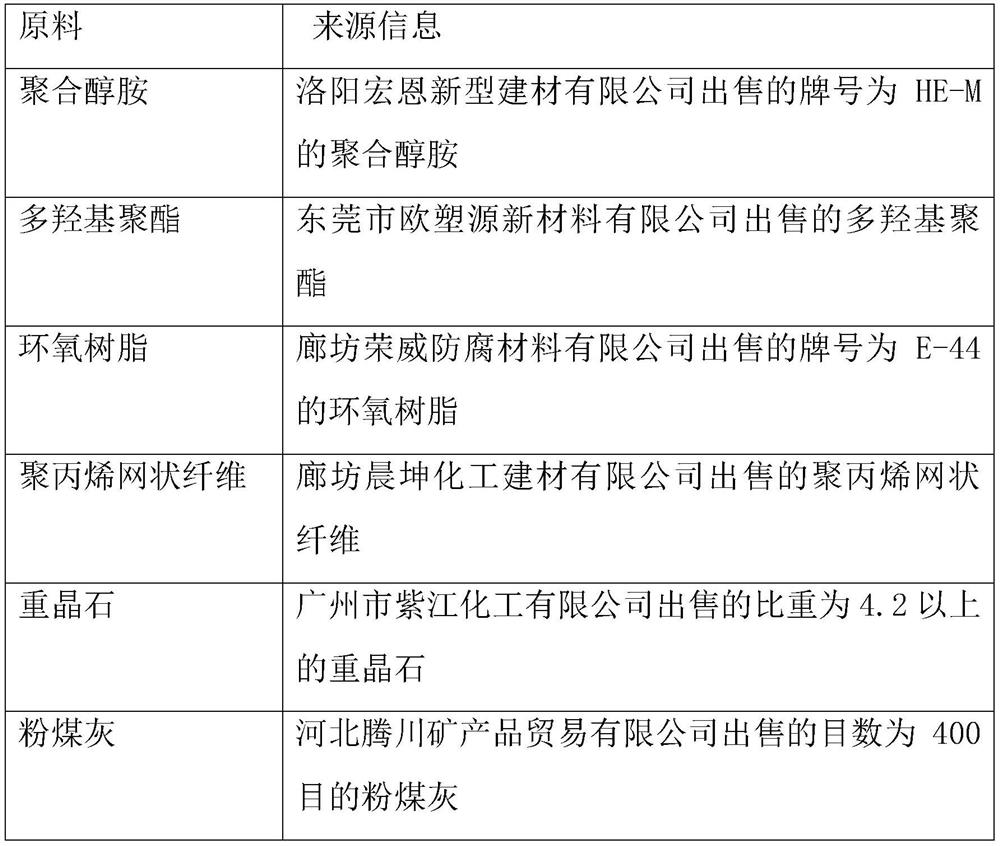

[0057]The embodiment of the present application discloses a concrete applied to large-volume radiation-proof buildings, including a steel skeleton and a concrete layer. The concrete layer is prepared from concrete grout, and the concrete grout includes the following components:

[0058] Cement, sand, gravel, barite, polyolamine, polyol polyester, epoxy resin, water.

[0059] In Examples 1-3, see Table 2 for the input amount (unit Kg) of each component.

[0060] Table 2

[0061] Example 1 Example 2 Example 3 cement 100 100 100 sand 220 230 240 gravel 240 250 260 Barite 90 100 110 polyolamine 0.2 0.35 0.5 polyol polyester 1 1.5 2 epoxy resin 6 8 10 water 60 63 66

[0062] The preparation method of concrete slurry comprises the following steps:

[0063] Step 01), adding cement, sand, gravel, polyalcohol amine, polyhydroxy polyester and water into the stirring tank, and stirring for 60 s at a rota...

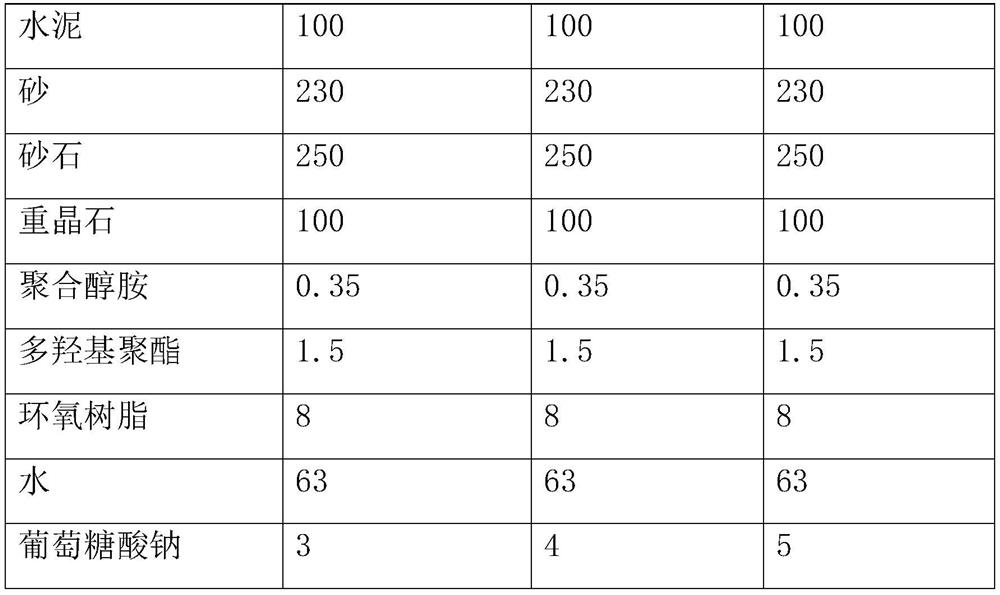

Embodiment 4-6

[0067] The embodiment of the application discloses a concrete slurry:

[0068] Compared with embodiment 2, the difference only lies in:

[0069] Concrete grout also includes the following components:

[0070] sodium gluconate.

[0071] In Examples 4-6, see Table 3 for the input amount (unit Kg) of each component.

[0072] table 3

[0073]

[0074]

[0075] Step 01), sodium gluconate, cement, sand, gravel, polymerized alcohol amine, polyhydroxy polyester and water are added into the stirring tank, and stirred evenly.

Embodiment 7-9

[0077] The embodiment of the application discloses a concrete slurry:

[0078] Compared with embodiment 2, the difference only lies in:

[0079] Concrete grout also includes the following components:

[0080] Polypropylene mesh fibers.

[0081] In Examples 7-9, see Table 4 for the input amount (unit Kg) of each component.

[0082] Table 4

[0083]

[0084]

[0085] Step 01), polypropylene mesh fiber, cement, sand, gravel, polymerized alcohol amine, polyhydroxy polyester and water are added into the stirring tank, and stirred evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com