N-layer intensive reinforced steel cord

A steel cord, intensive technology, applied in the field of N-layer intensive reinforced steel cord, can solve the problems of high air content of steel cord, insufficient strength of steel cord, and ineffective penetration of rubber, etc., so as to improve the service life, Improved corrosion resistance, reduced air content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

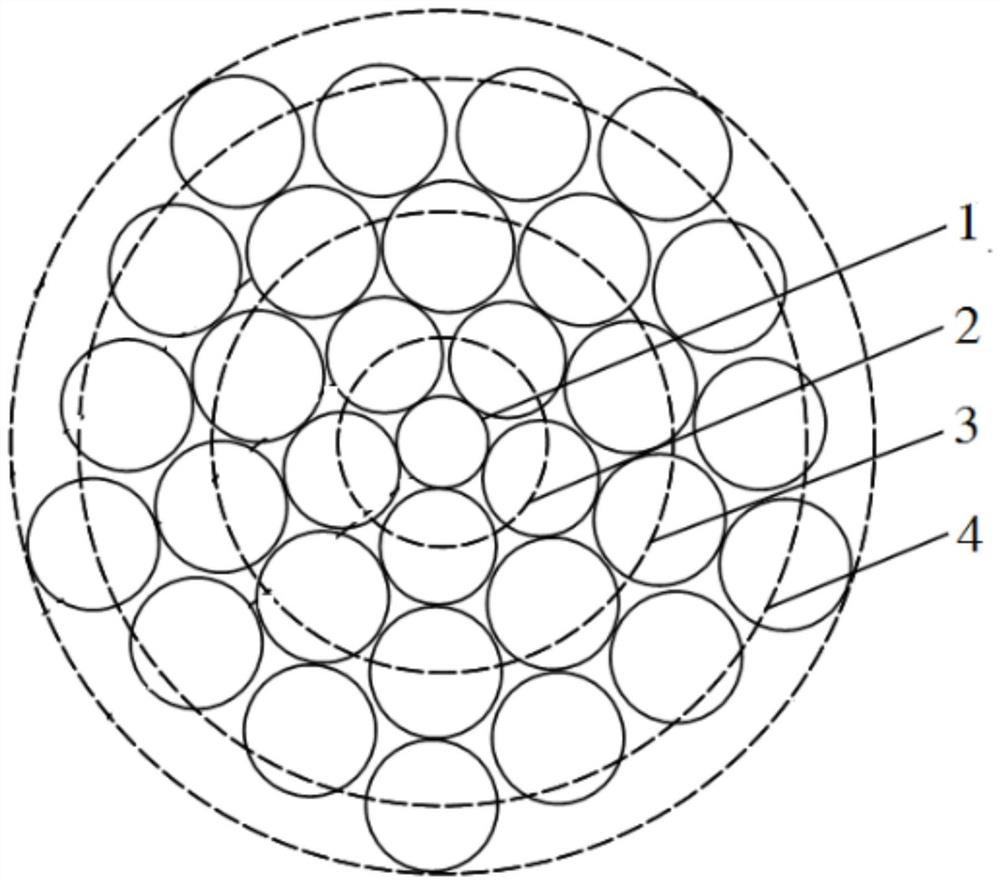

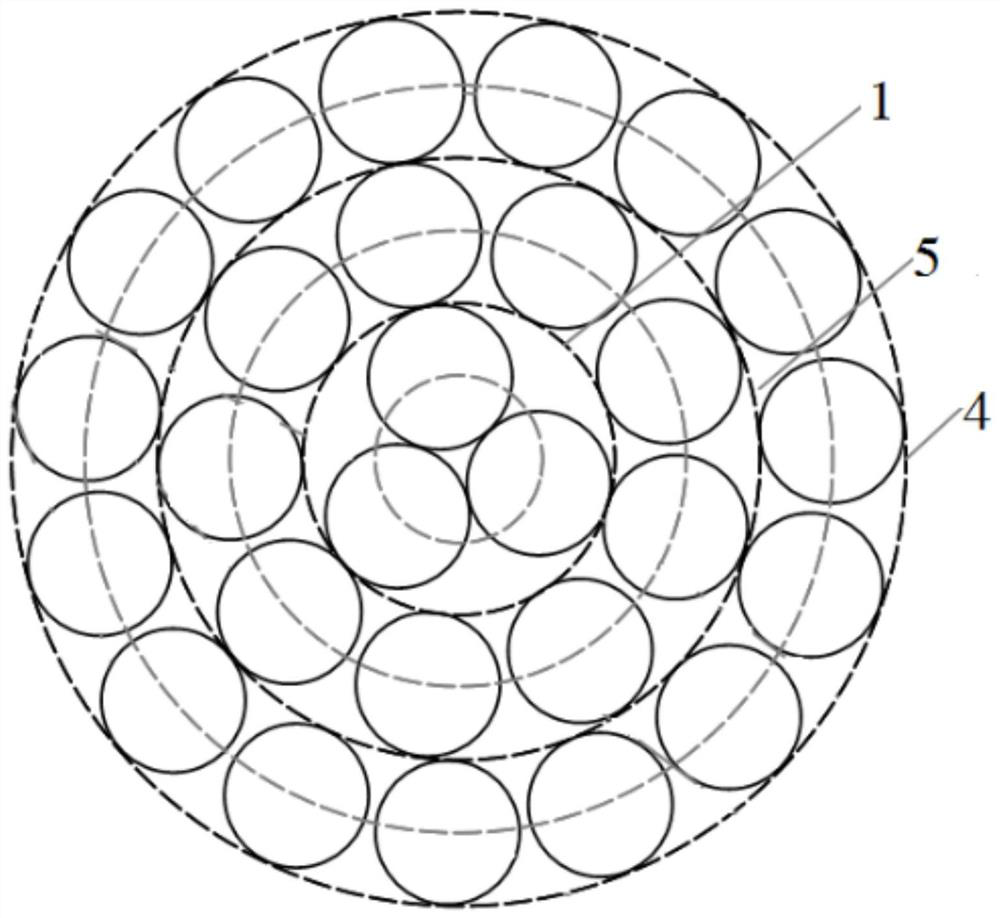

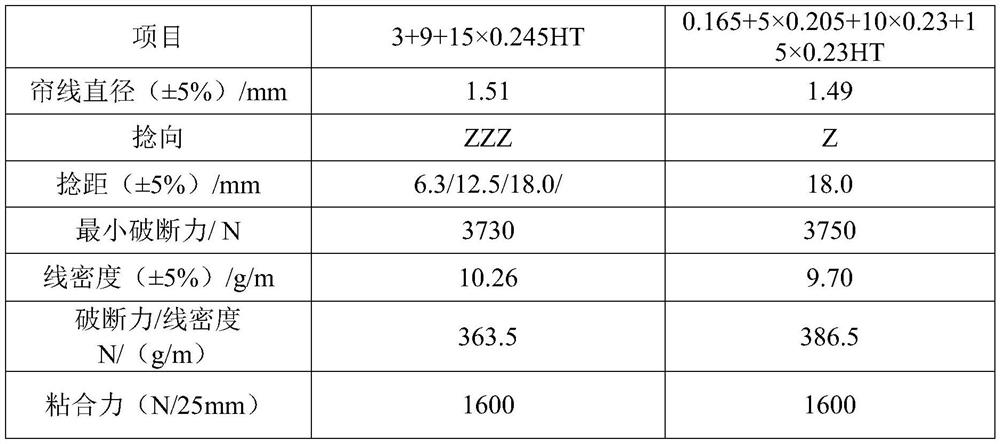

[0025] An N-layer intensive reinforced steel cord, including a core steel wire 1 with a diameter of 0.165mm, five second-layer steel wires with a diameter of 0.205mm 2, and ten third-layer steel wires with a diameter of 0.23mm 3 and fifteen outer-layer steel wires 4 with a diameter of 0.23 mm, the core steel wire 1 has no twisting, the twist direction of the second-layer steel wire 2, the third-layer steel wire 3 and the outer-layer steel wire 4 are the same, and the twist direction All are Z-twisted, the core strand steel wire 1 has no twist length, the lay length of the second layer strand steel wire 2, the third layer strand steel wire 3 and the outer layer strand steel wire 4 are the same, and the lay length is 18.0mm. The provided steel cords with 0.165+5×0.205+10×0.23+15×0.23HT structure are used as reinforcing frame materials for radial tires.

[0026] In the prior art, steel cords with a structure of 3+9+15×0.245HT are commonly used. The twist direction of strand stee...

Embodiment 2

[0031] An N-layer intensive reinforced steel cord, including a core steel wire 1 with a diameter of 0.15mm, five second-layer steel wires with a diameter of 0.19mm 2, and ten third-layer steel wires with a diameter of 0.215mm 3 and fifteen outer-layer steel wires 4 with a diameter of 0.215mm, the core steel wire 1 has no braiding and twisting, the twist direction of the second-layer steel wire 2, the third-layer steel wire 3 and the outer-layer steel wire 4 is the same, and the twist direction All are Z-twisted, the core strand steel wire 1 has no twist length, the lay length of the second layer strand steel wire 2, the third layer strand steel wire 3 and the outer layer strand steel wire 4 are the same, and the lay length is 18.0mm. The provided steel cords of 0.15+5×0.19+10×0.215+15×0.215ST structure are used as reinforcing frame materials for radial tires.

[0032] In the prior art, steel cords with a structure of 3+9+15×0.225ST are commonly used, with a diameter of 1.39mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com