Slip form concrete continuous pouring vehicle set and pouring method

A concrete and slip-form technology, applied in construction, building structure, construction material processing, etc., can solve the problems of affecting construction efficiency, heavy downline, concrete spillage, etc., to improve construction efficiency and quality, simplify construction process, The effect of strong driving dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The technical scheme of the present invention will be described in detail below in conjunction with the drawings:

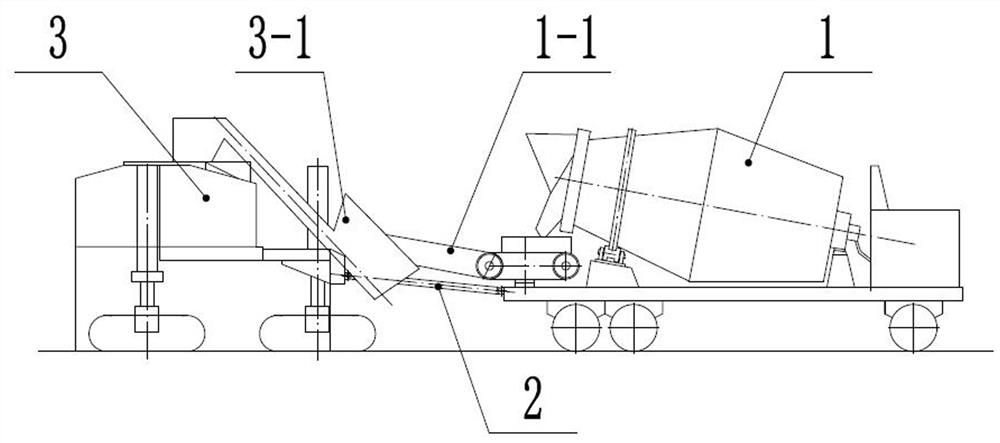

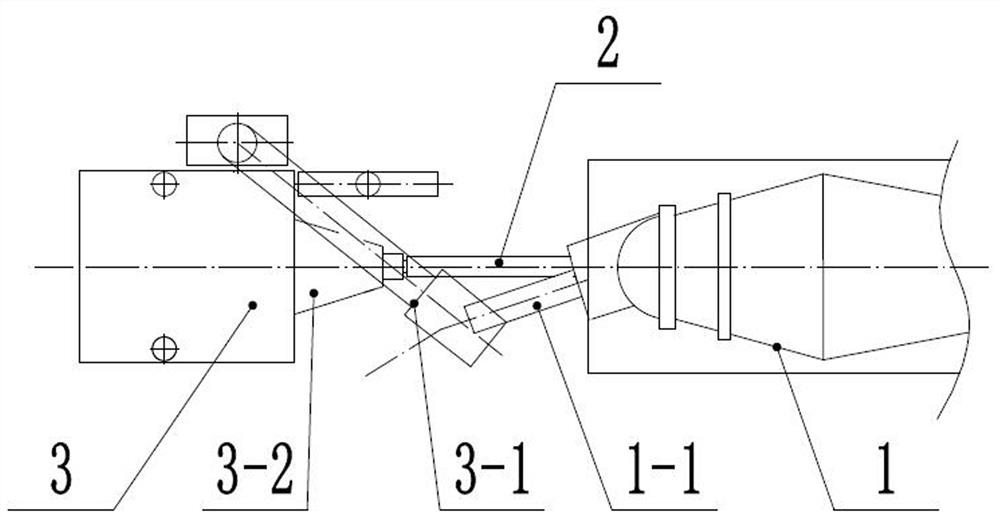

[0021]Such asfigure 1 with2, A slipform concrete continuous pouring vehicle group, comprising a mixer truck 1 and a sliding mold machine 3 arranged in front and rear, and the mixer truck 1 and the sliding mold machine 3 are connected by a connecting rod 2. Specifically, a bracket 3-2 is provided at the middle of the front end of the sliding mold machine 3, and the front end of the bracket 3-2 is provided with a shackle for connecting the connecting rod 2. The bracket 3-2 is integrated with the front wheel frame of the sliding mold machine 3. The connecting rod 2, the central axis of the sliding mold machine 3 and the central axis of the mixer truck 1 are located on the same vertical plane, which facilitates pushing the mixer truck 1 without affecting the normal operation of the sliding mold machine 3.

[0022]The discharging mechanism 1-1 of the mixer truck 1 is overla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com