Ladle turret speed reducer of steel mill

A technology of large-pack turntable and reducer, which is applied in the direction of mechanical equipment, transmission parts, gear transmission, etc., can solve the problems of turntable shutdown, production impact, and drive motor prone to failure, etc., to improve applicability, Avoid the effect of motor installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

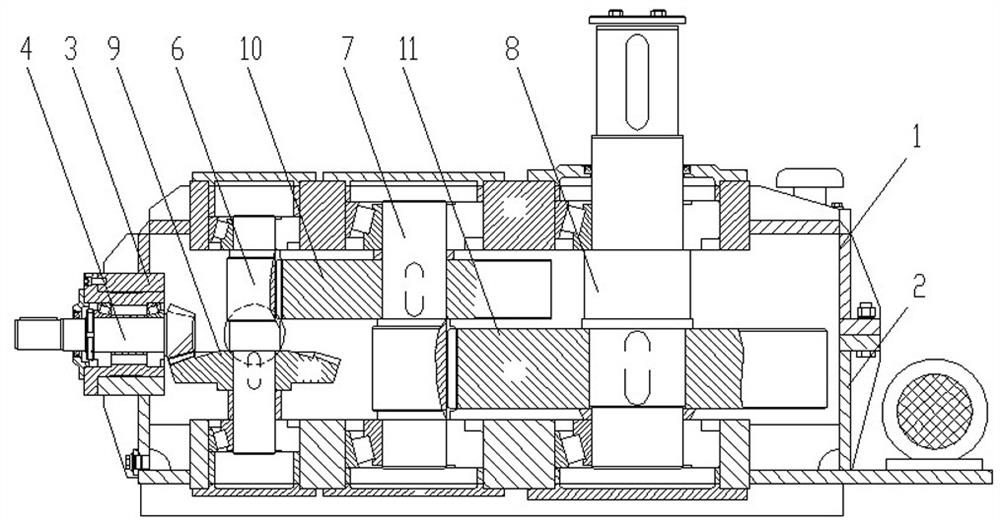

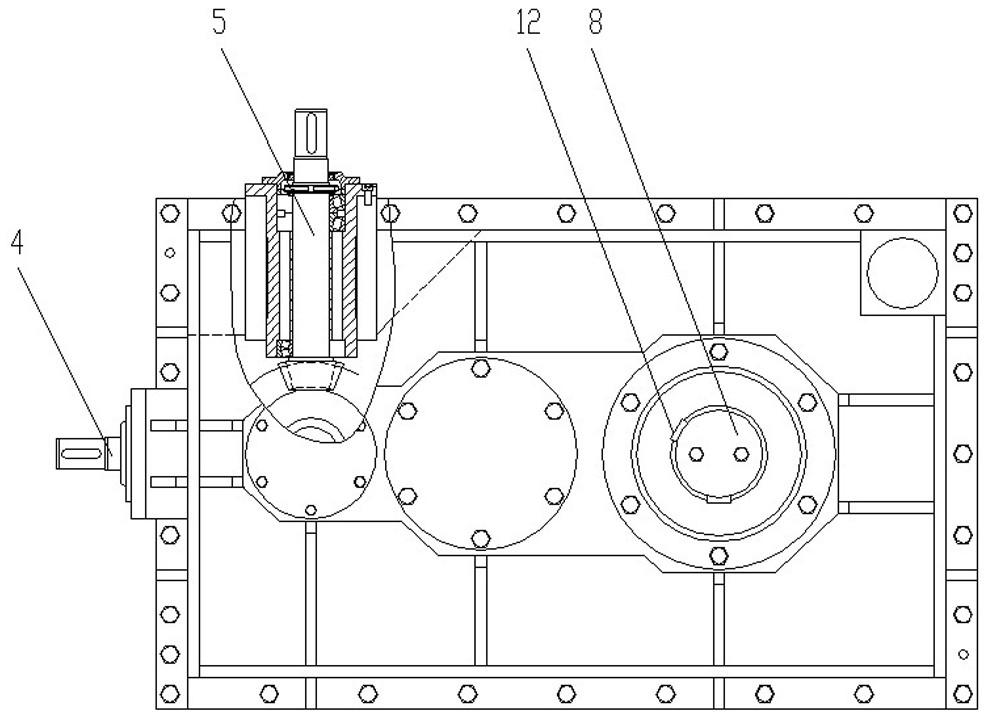

[0011] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings: as shown in the figure, a steel mill ladle rotary table reducer includes a box body, and the box body is composed of an upper box body 1 and a lower box body 2, and the upper box body 1 and the lower box body 2. 1. The first input shaft 4 and the second input shaft 5 are supported by the bearing housing 3 between the lower box body 1 and 2. The first and second output shafts 4 and 5 are horizontal axes and perpendicular to each other. The first and second input shafts 4 and 5 are bevel gear shafts, the extended end of the first input shaft 4 is located on the left side of the casing, and the extended end of the second input shaft 5 is located at the rear side of the casing. The first intermediate shaft 6, the second intermediate shaft 7 and the output shaft 8 are vertically supported by bearings in the box. The first intermediate shaft...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap