Unpowered multi-channel flue gas heating device and method

A flue gas heating, multi-channel technology, applied in the field of thermal power plant equipment, can solve the problems of increased coal consumption, low inlet flue temperature of low-load denitration, insufficient drying capacity of pulverizing system, etc., so as to improve boiler combustion efficiency and meet deep peak regulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

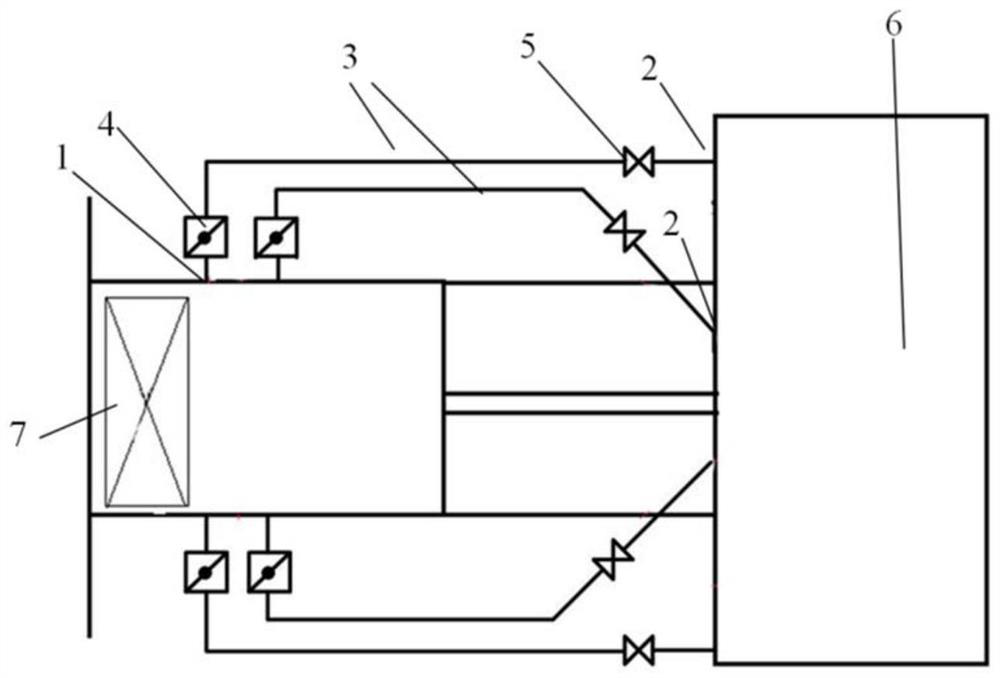

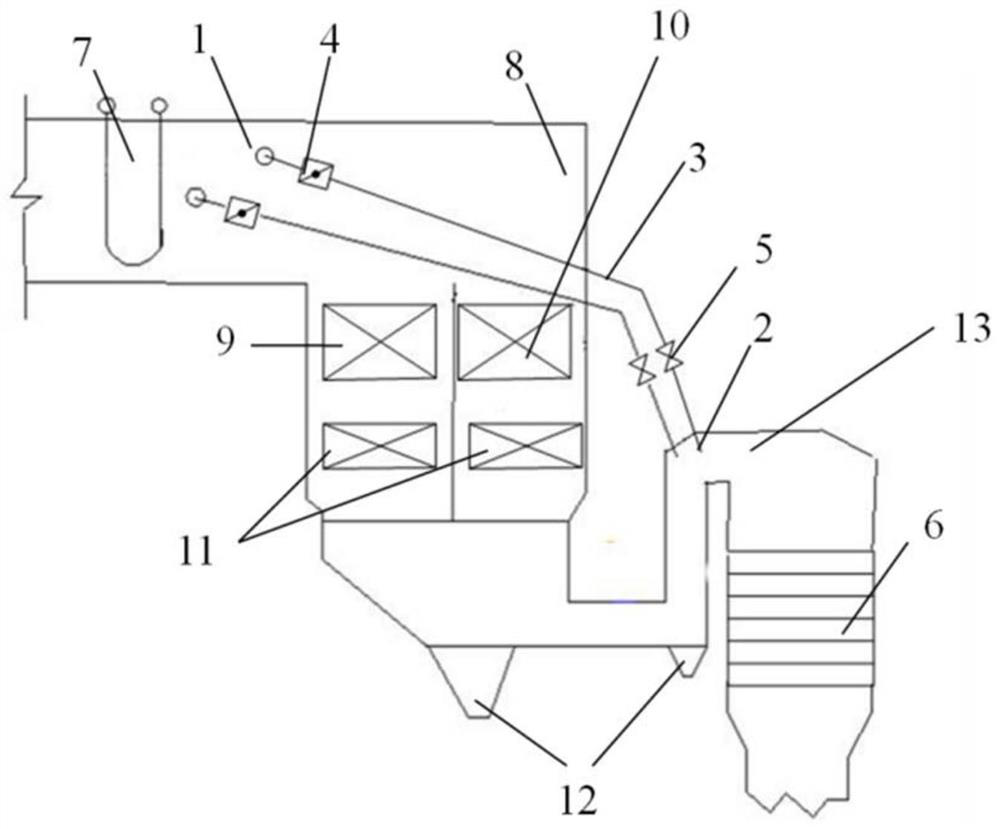

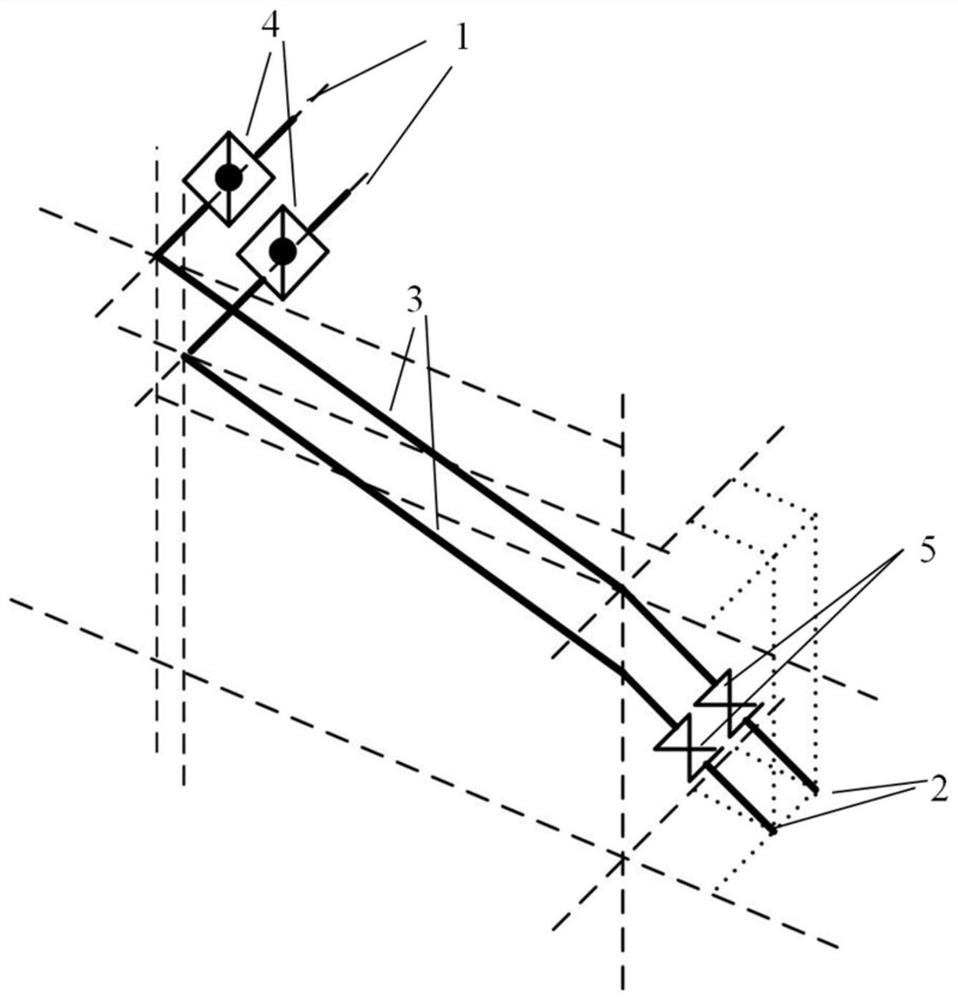

[0047] The test unit is a 350MW unit boiler in Fuxin Power Plant. The flue width of the SCR reactor is 12m, using 4 circular pipes and 4-point mixing technology. The preferred choice is about 500mm behind the high temperature superheater in the horizontal flue. The distance between adjacent mixing points is about 2.4m, and the material is 12cr1MoV. The insertion point is at the front end of the horizontal flue of the SCR reactor, which is also the highest point of the flue gas space of the SCR reactor. Since there is no heating surface at the insertion point, the pipe is inserted at 45° to a depth of about 250mm and sealed. Install shut-off door and adjustment door 2 door control, choose heat-resistant material. The extraction point is selected after the high-temperature superheater in the horizontal flue, the extraction point smoke temperature is 500℃~600℃, and the negative pressure is 150Pa~200Pa. The insertion point is at the highest point of the SCR reactor, where the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com