A high-precision wind tunnel force balance for coaxial parallel axial load measurement

An axial load, force-measuring balance technology, used in measuring devices, aerodynamic tests, machine/structural component testing, etc. problems, to achieve the effect of broadening the micro-measurement capability, shortening the development cycle, and weakening the design contradiction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with the examples.

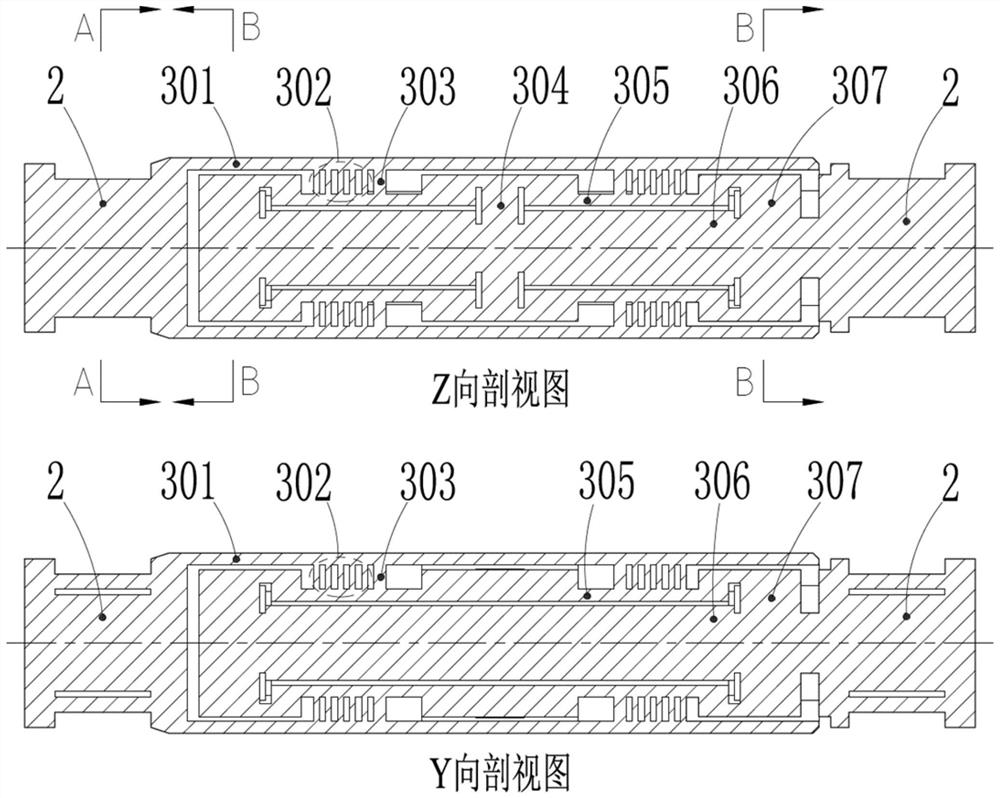

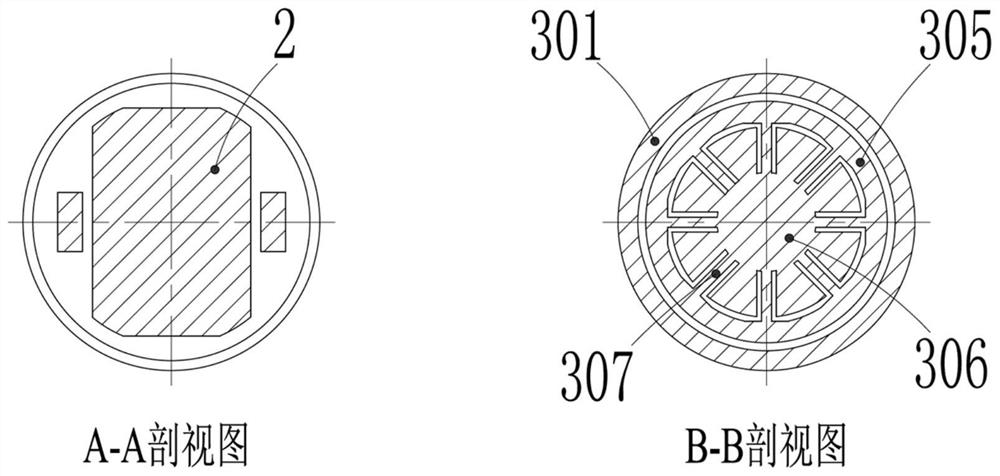

[0028] The invention provides a novel wind tunnel strain balance for high-precision axial load measurement. Based on the additive manufacturing (metal direct rapid prototyping) method, a balance design with a better structural form is realized, aiming at improving the measurement accuracy and resolution of the axial loads Mx and X. Additive manufacturing technology has significant advantages in shortening the development cycle of the balance, reducing the cost, increasing the flexibility of the balance structure design, and avoiding the limitation of the machining method on the design of the better balance structure. The measurement resolution, decoupling characteristics and load matching capability of the balance's axial load are made possible.

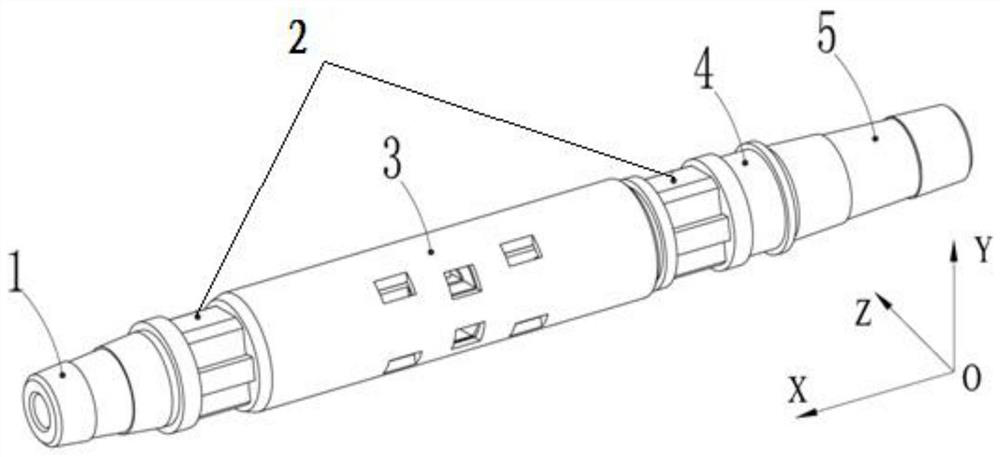

[0029] High-precision wind tunnel force balances, such as Figure 1 to Figure 3 As shown, it specifically includes a front cone 1, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com