Lithium ion battery tab fracture detection method

A technology of lithium ion battery and detection method, which is applied in the direction of measuring electricity, measuring device, measuring electrical variable, etc., can solve the problems of difficult identification, easy omission of judgment, rupture of tabs of laminated lithium ion battery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for detecting the breakage of a tab of a lithium-ion battery, comprising:

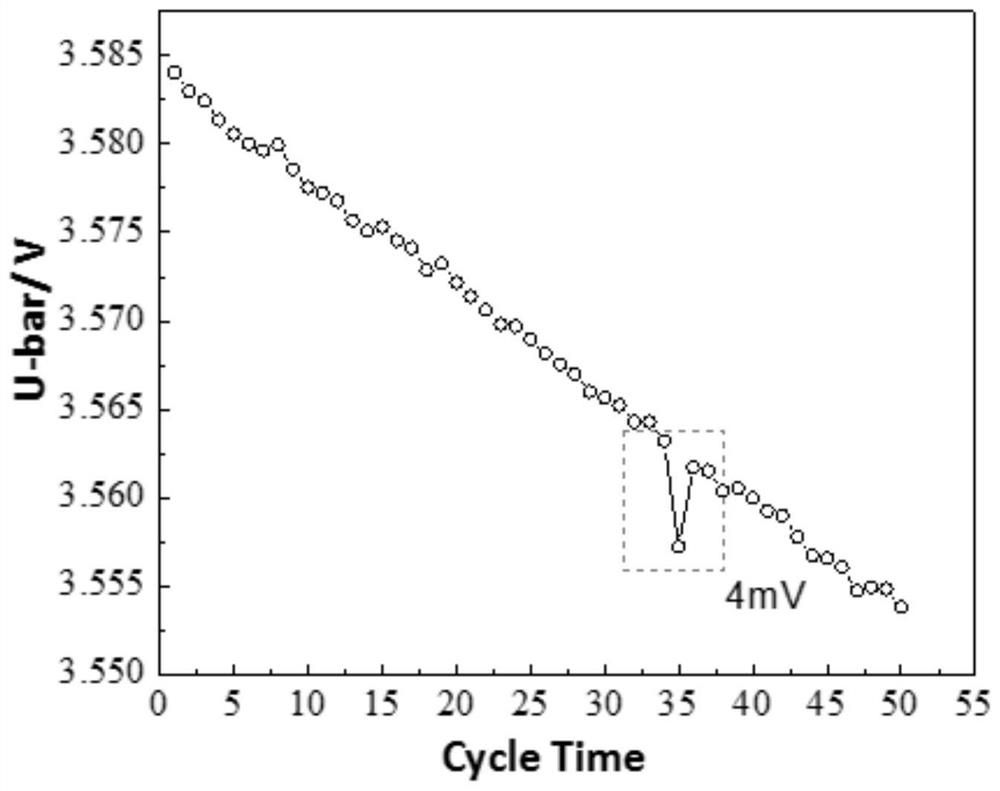

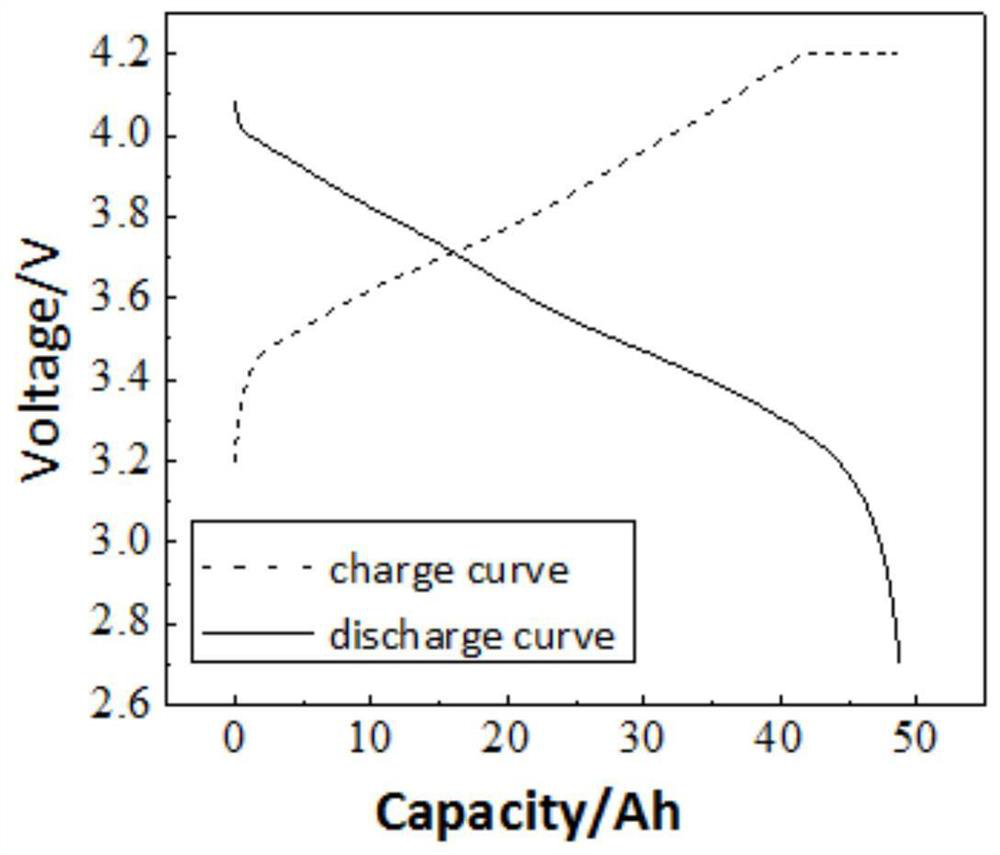

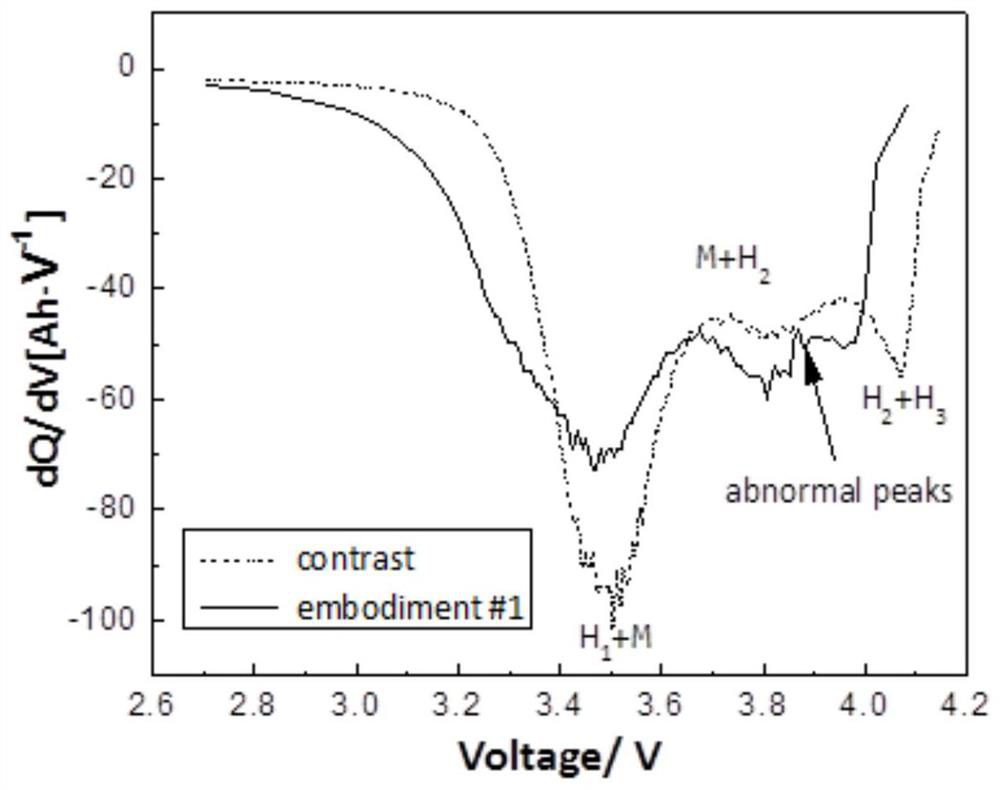

[0051] A 45Ah stacked lithium-ion battery of NCM / C system was charged and discharged 50 times. The charge and discharge system was charged to 4.2V with a constant current of 1C, charged to a current of 0.05C with a constant voltage, rested for 10 minutes, and discharged at 1C. to 2.7V. Record the discharge energy and discharge capacity of each cycle, calculate the average voltage of each discharge, and calculate the average voltage of discharge: Among them, ∫u(t)I(t)dt is the discharge energy, and ∫I(t)dt is the battery capacity. Establish the charge and discharge curve model, after calculation, such as figure 1 As shown, the average voltage jumps by 4mV at the 35th cycle. Taking the 35th charge-discharge cycle as an abnormal charge-discharge cycle, compare the data of the 35th charge-discharge cycle with the comparative example, wherein the battery capacity, chemical system and cha...

Embodiment 2

[0055] A method for detecting the breakage of a tab of a lithium-ion battery, comprising:

[0056] A 45Ah laminated lithium-ion battery of the NCM / C system carries out 100 charge and discharge cycles, and the battery charge and discharge system is the same as in Example 1, and the average discharge voltage of each charge and discharge cycle is calculated, and the average discharge voltage of the charge and discharge cycle is calculated Method is the same as embodiment one.

[0057] Such as Figure 4 As shown, the average discharge voltage fluctuated after the 60th cycle, and the average voltage fluctuated the most at the 70th cycle, with an average voltage fluctuation of 47.11% (capacity fluctuation 41.46%), and the voltage change became flat after the 75th cycle, and the 76th cycle The maximum fluctuation of the secondary voltage is 4mV. During the 73rd discharge cycle, the voltage fluctuated downward in a zigzag form between 3.550V and 3.650V, with a maximum fluctuation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com