Pre-stress variable cross-section box girder steel bar collision detection method based on BIM technology

A technology of collision detection and prestressing, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve problems such as long construction period, increased operating cost, and increased workload, so as to shorten the construction period and reduce construction cost. Operational cost and effect of reducing rebar adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

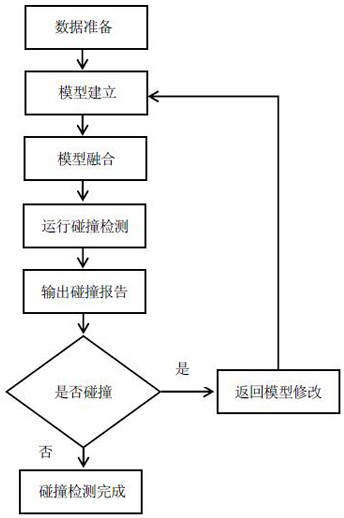

[0062] Application of the present invention based on BIM technology prestressed box girder steel bar collision detection method with variable cross-section, it is specifically as follows:

[0063] Step A. Data preparation

[0064] Collect and organize the reinforcement layout at the end of the main girder, the prestressed layout of the main girder, and the detailed structural drawings of the main body of the bridge. After screening, collect and sort out the required drawings to obtain the basic data for building the model;

[0065] Step B. Model building

[0066] The model is established in Revit software, and the Revit project includes 2 or more basic models.

[0067] In the step B model building, including transverse prestressed reinforcement model, vertical prestressed reinforcement model, longitudinal prestressed reinforcement model.

[0068] Using Revit software, according to the layout diagram of the main beam end reinforcement and the layout diagram of the prestressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com