Forage grass crushing device for animal husbandry

A pulverizing device and animal husbandry technology, applied in agriculture, agricultural machinery and implements, removing smoke and dust, etc., can solve the problems of inability to pulverize pasture, reduce the pulverization efficiency of pasture, and achieve the effect of improving the pulverizing effect and expanding the pulverizing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

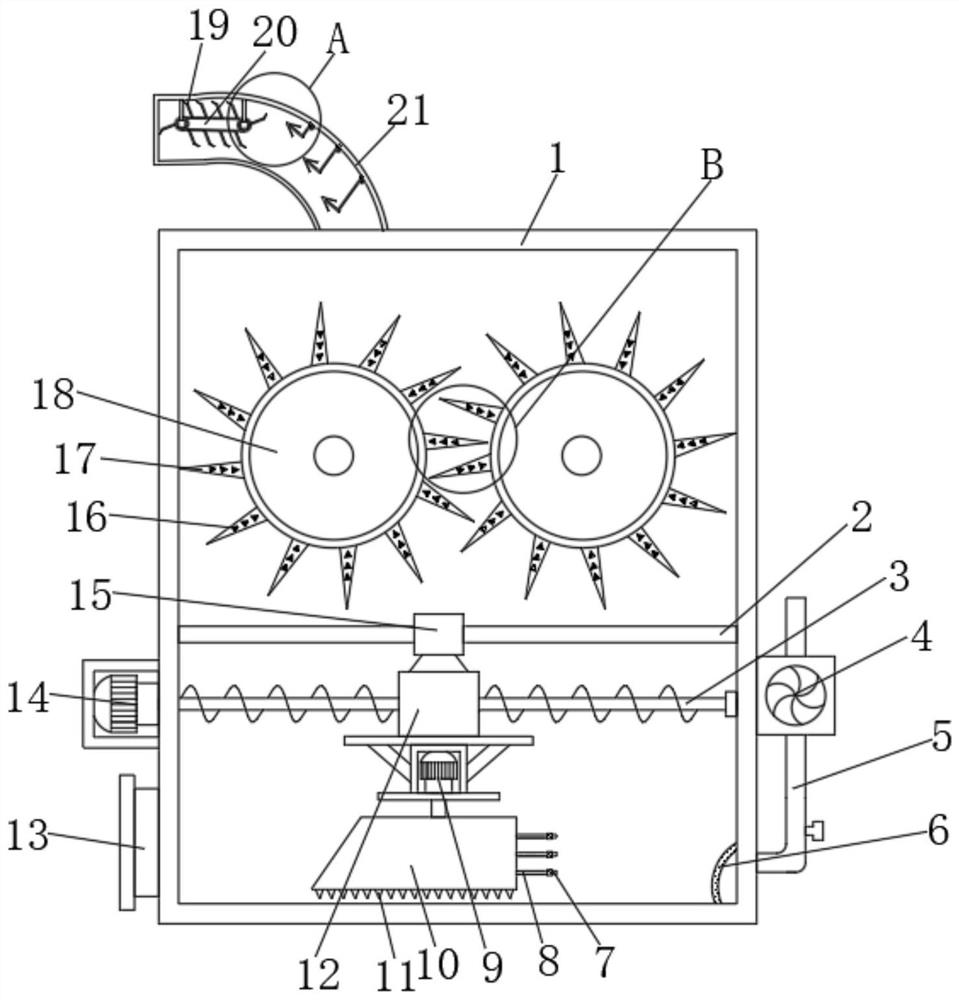

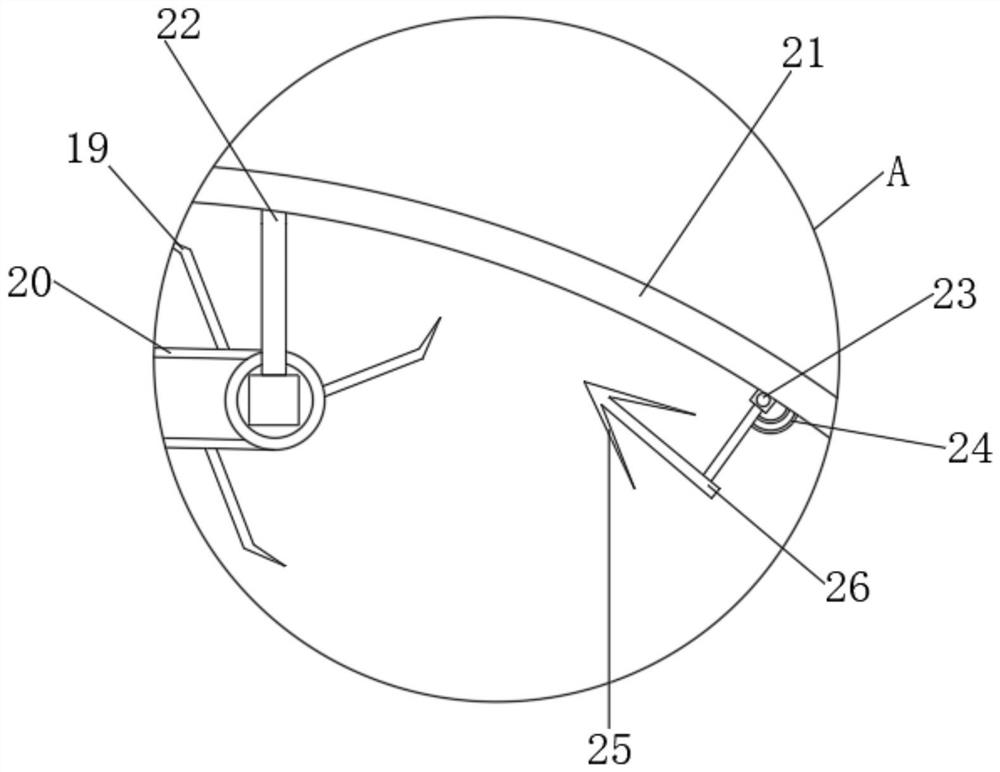

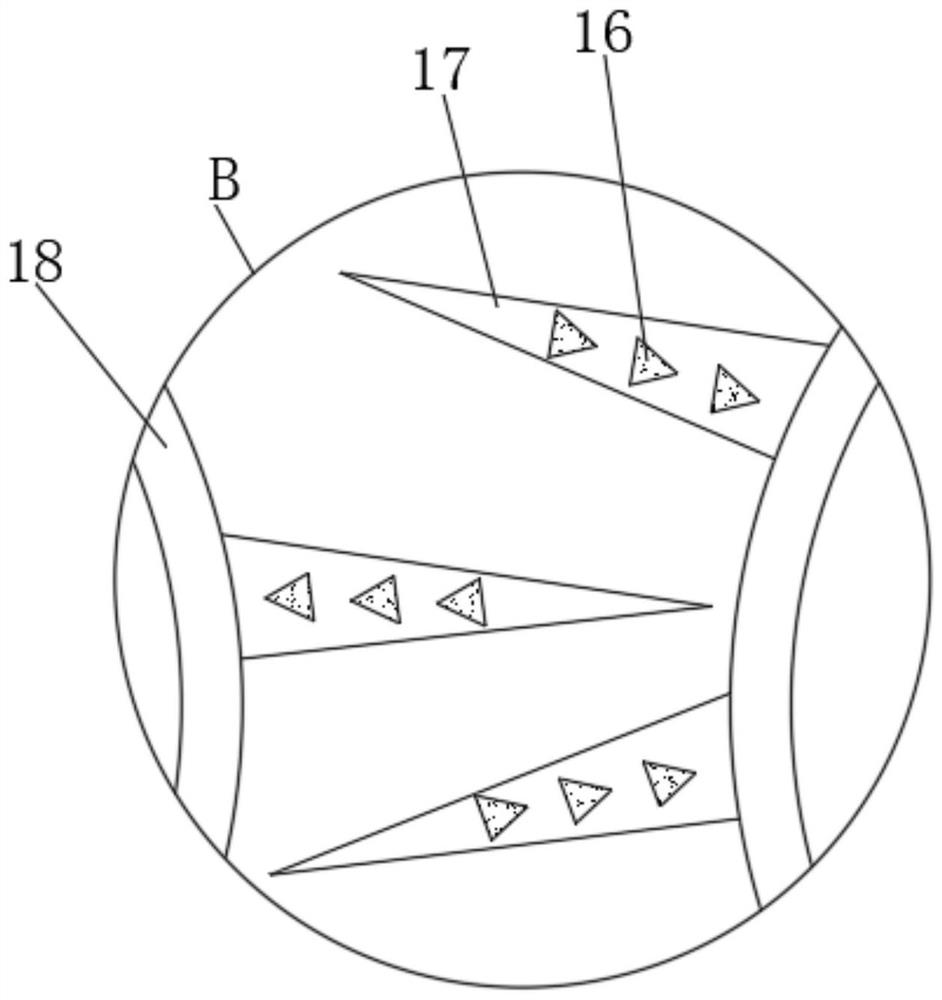

[0030] refer to Figure 1-5 , a pasture grass crushing device for animal husbandry, comprising a box body 1, a feed pipe 21 is inserted into the top outer wall of the box body 1, and a third motor is connected to the outer wall of one side of the box body 1 by bolts, and the output shaft of the third motor One end is provided with a connecting column 18, and the peripheral outer wall of the connecting column 18 is connected with crushing teeth 17 equidistant and annularly distributed by bolts, and the outer wall of one side of the box body 1 is connected with a second motor 14 by bolts, and the second motor 14 The outer wall at one end of the output shaft is fixedly connected with a threaded screw 3, the outer wall of the threaded screw 3 is sleeved with a threaded sleeve 12, and the bottom outer wall of the threaded sleeve 12 is connected with a mounting plate by bolts, and the bottom outer wall of the mounting plate is connected by bolts. There is a first motor 9, and one en...

Embodiment 2

[0034] refer to Figure 6 , a pasture grass crushing device for animal husbandry. Compared with Embodiment 1, in this embodiment, one side of the outer wall of the box body 1 is connected with a dust removal box 29 by bolts, and the inner walls of both sides of the dust removal box 29 are connected with clamping seats by bolts. The bottom inner wall of the seat is clamped with a clamping rod 30, and one end outer wall of the clamping rod 30 is fixedly connected with a dust filter bag 28, and the both sides inner walls of the dust removal box 29 are all connected with a filter screen 31 by bolts.

[0035] Working principle: When people need to crush the pasture, they can first add the pasture to the inside of the box 1 through the feed pipe 21 for crushing work. At the same time, the cross section of the feed pipe 21 is arc-shaped to avoid dust during the process of adding pasture In the case of flying, when pasture is fed into the feeding pipe 21, the gear bar 19 on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com