Heat-not-burn cigarette suitable for infrared heating device

A heat-not-burn, infrared heating technology, used in applications, tobacco, cigar manufacturing, etc., can solve the problems of reducing the radiation efficiency of tobacco substances, low thermal efficiency, etc., and achieve broad market prospects, enhance wrapping performance, improve heating efficiency and heating The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

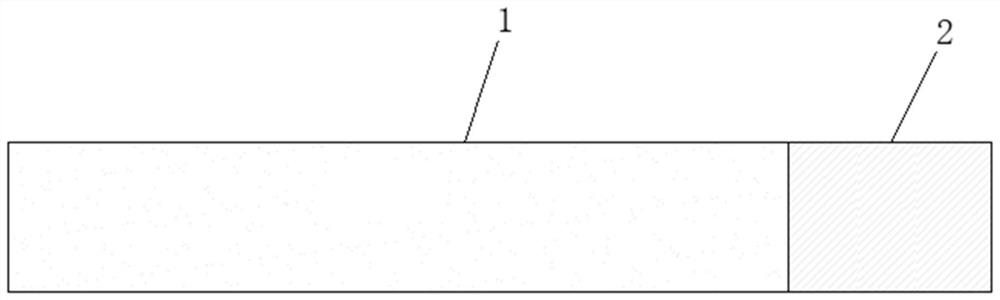

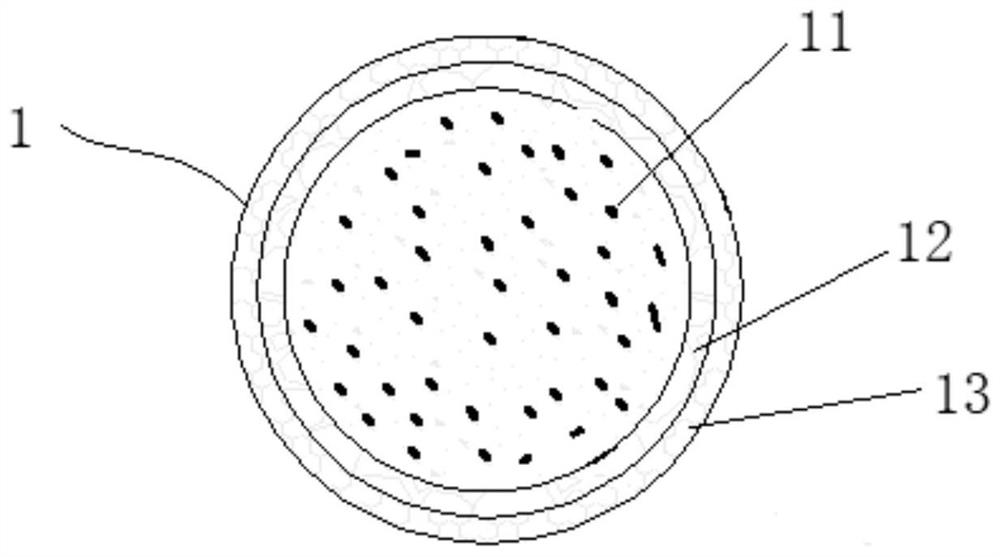

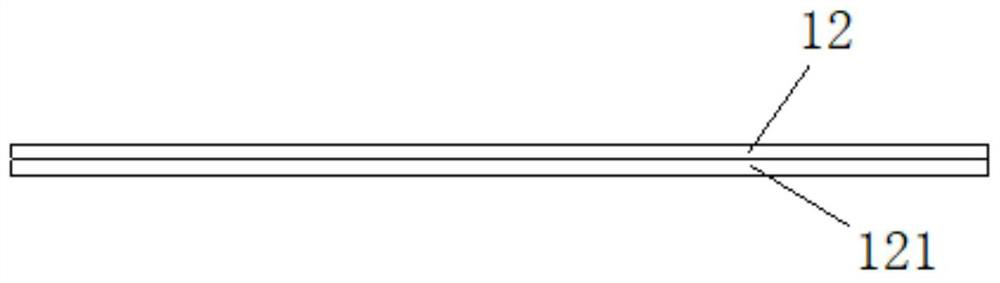

[0054] Such as Figure 1~3 As shown, the heat-not-burn cigarette suitable for the infrared heating device in the first embodiment includes a tobacco segment 1 and a filter rod segment 2 . Wherein, the tobacco segment 1 includes a tobacco substance 11 for generating an inhalable aerosol after being heated and a wrapping layer 12 wrapped outside the tobacco substance 11 . The transmittance of the wrapping layer 12 to infrared electromagnetic waves with a wavelength in the range of 1.5-25 microns is 55%. The inner surface of the wrapping layer 12 is provided with an oil-proof layer 121 for preventing the glycerin of the tobacco segment 1 from seeping out. The transmittance of the oil-repellent layer 121 to infrared electromagnetic waves with a wavelength in the range of 1.5-25 micrometers is above 70%. The tobacco segment 1 also includes a wrapping paper layer 13 wrapped on the outer surface of the wrapping layer 12 .

[0055] Further, the quantitative control of the rolled pa...

Embodiment 2

[0061] The difference between the second embodiment and the first embodiment is that the weight of the roll paper layer 13 is controlled at 30 g / m2. The air permeability of the micropores provided on the roll paper layer 13 is 500CU. Each component of the oil-proof layer 121 is composed as follows according to parts by weight:

[0062]

[0063]

Embodiment 3

[0065] The difference between the third embodiment and the second embodiment is that the components of the oil-proof layer 121 are composed as follows in parts by weight:

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air permeability | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com