Method for improving center segregation of ultra-thick slab peritectic steel

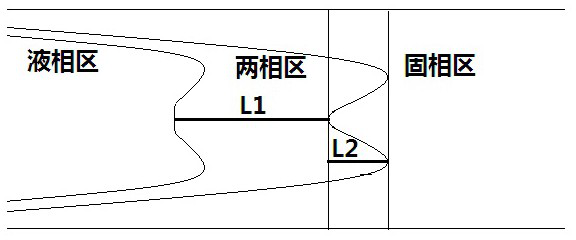

A thick slab and center point technology, which is applied in the field of improving the center segregation of ultra-thick slab peritectic steel, can solve the problem of not being able to effectively improve the internal quality of ultra-thick slabs and not considering the influence of solidification characteristics of W-shaped liquid cores in continuous casting of slabs and other problems, to achieve the effect of obvious internal quality improvement, easy realization, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Ultra-thick slab peritectic steel with a thickness specification of 460mm and a carbon content of 0.096wt% was selected for treatment. The composition of the steel grade is as follows: C0.096, Si 0.197, Mn 1.478, P 0.022, S 0.002, Als 0.025. In the continuous casting process, the ultra-thick slab is pressed, and the specific steps are as follows:

[0036] (1) In the two-phase region, when 0.05 ≤ fs <0.35, the reduction is 4.5mm; when 0.35 ≤ fs <0.55, the reduction is 5.0mm; when 0.55 ≤ fs <0.90, the reduction is 6.5mm ; When 0.90 ≤ fs ≤ 1.0, the reduction is 8.0mm; in the solid phase region, when dt≤80℃, the reduction is 5mm.

[0037] (2) When this scheme is adopted, the central segregation ratings of the 1 / 4, 1 / 2, and 3 / 4 positions of the slab width are all C1.0, and the internal quality of the ultra-thick slab peritectic steel is significantly improved.

Embodiment 2

[0039] For ultra-thick slab peritectic steel with a thickness specification of 480mm and a carbon content of 0.091wt%, the composition of the steel grade is as follows: C 0.091, Si 0.192, Mn 1.486, P 0.014, S 0.002, Als 0.025. In the continuous casting process, the ultra-thick slab is pressed, and the specific steps are as follows:

[0040] (1) In the two-phase region, when 0.05 ≤ fs <0.35, the reduction is 1.0mm; when 0.35 ≤ fs <0.55, the reduction is 1.5mm; when 0.55 ≤ fs <0.90, the reduction is 2.0mm ; When 0.90 ≤ fs ≤ 1.0, the reduction is 3.0mm; in the solid phase region, when dt≤80℃, the reduction is 1.5mm.

[0041] (2) When this scheme is adopted, the central segregation ratings of the 1 / 4, 1 / 2, and 3 / 4 positions of the slab width are all C1.0, and the internal quality of the ultra-thick slab peritectic steel is significantly improved.

[0042] The method of the present invention adopts a 475mm ultra-thick slab casting machine, and through a specific pressing process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com