Method for relieving center segregation of super-thick plate blank high-carbon steel

A thick slab, high carbon steel technology, applied in the field of improving the center segregation of super thick slab high carbon steel, can solve the problem that the internal quality of super thick slab cannot be effectively improved, and the solidification characteristics of slab continuous casting W-type liquid core are not considered. Influence and other problems, to achieve the effect of obvious internal quality improvement, easy realization and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] For ultra-thick slab high-carbon steel with a thickness specification of 460mm and a carbon content of 0.493wt%, the composition of the steel grade is as follows: C-0.493, Si-0.248, Mn-0.519, P-0.016, S-0.006, Als-0.008. In the continuous casting process, the ultra-thick slab is pressed, as follows:

[0034] (1) When 0.2 ≤ fs <0.32, the reduction is 6.5mm; when 0.32 ≤ fs <0.58, the reduction is 8.5mm; when 0.58≤fs ≤1.0, the reduction is 9.0mm; when dt≤60℃ , the reduction amount is 4.5mm.

[0035] (2) When this scheme is adopted, the central segregation ratings of the 1 / 4, 1 / 2, and 3 / 4 positions of the slab width are all C1.0, and the internal quality of the ultra-thick slab high-carbon steel is significantly improved.

Embodiment 2

[0037] For the ultra-thick slab high-carbon steel with a thickness specification of 480mm and a carbon content of 0.486wt%, the steel composition is as follows: C-0.486, Si- 0.247, Mn- 0.520, P- 0.023, S-0.006, Als- 0.004 . In the continuous casting process, the ultra-thick slab is pressed, and the specific steps are as follows:

[0038] (1) When 0.2 ≤ fs <0.32, the reduction is 1.5mm; when 0.32 ≤ fs <0.58, the reduction is 2.5mm; when 0.58≤fs ≤1.0, the reduction is 3.0mm; when dt≤60℃ , the reduction amount is 1.5mm.

[0039] (2) When this scheme is adopted, the central segregation ratings of the 1 / 4, 1 / 2, and 3 / 4 positions of the width of the slab are all C1.5, and the internal quality of the ultra-thick slab high-carbon steel is significantly improved.

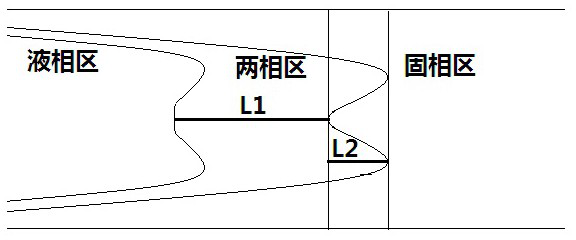

[0040] The method of the present invention aims at the continuous casting characteristics of the W-shaped solidification end of the ultra-thick slab, taking the 1 / 2 position of the slab width as the calculation basis, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com