New energy automobile hub grinding device

A new energy vehicle, wheel hub technology, applied in the direction of grinding drive device, grinding machine, grinding workpiece support, etc., can solve the problems of poor grinding flexibility, low grinding efficiency, affecting the overall appearance of the product, etc., to achieve flexible use and good grinding effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

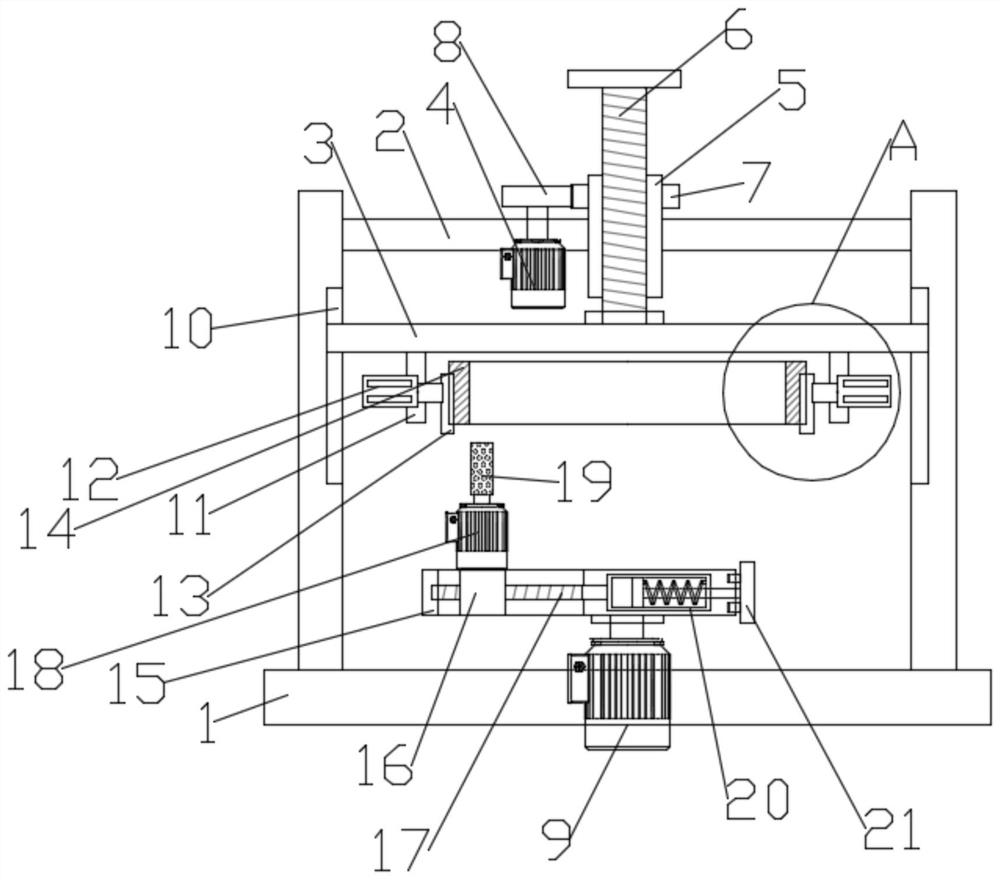

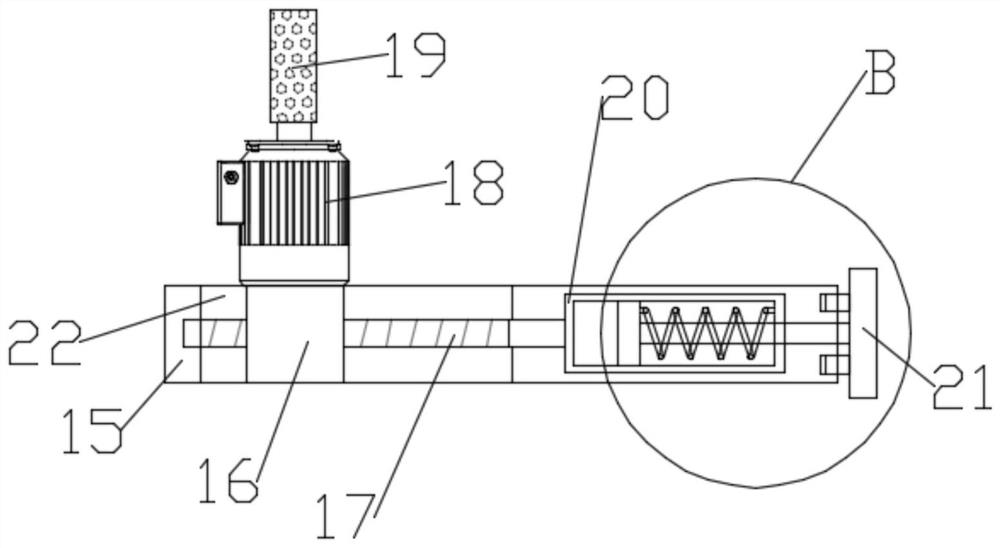

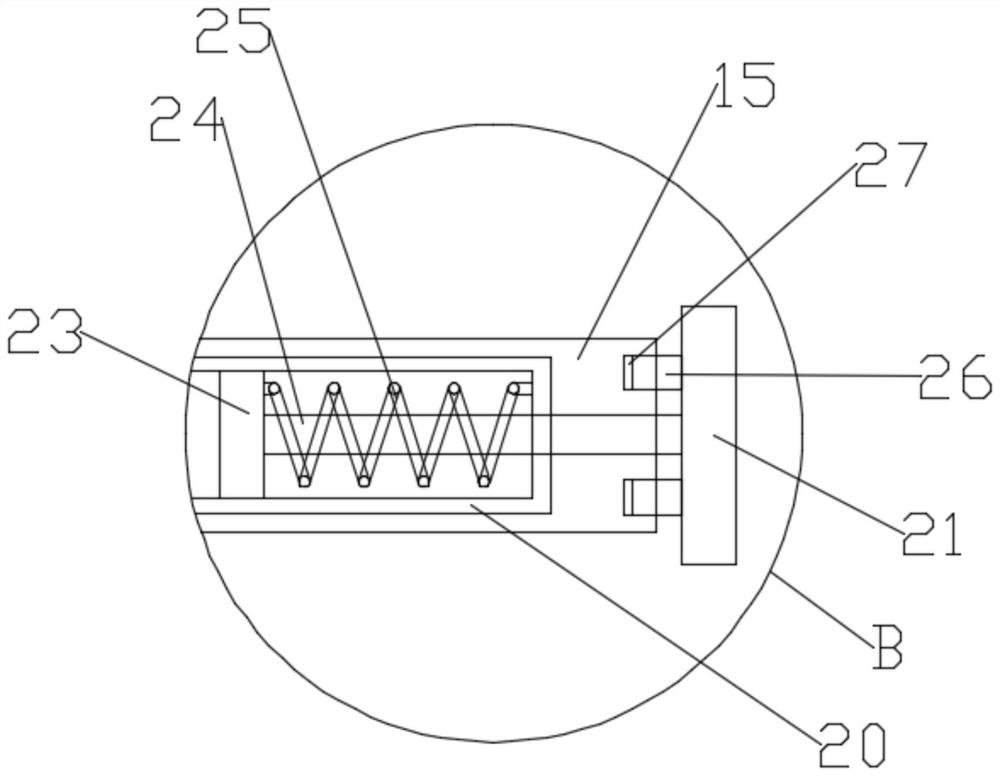

[0030] Such as figure 1 As shown, in the embodiment provided by the present invention, a new energy vehicle wheel hub grinding device includes a base 1, a bracket 2 is fixedly arranged on the base 1, and a bracket 2 for adjusting the lifting plate 3 is arranged on the top of the bracket 2. The lifting assembly at the height of the center; the inner walls of both sides of the support 2 are provided with guide rail grooves 10, and the end of the lifting plate 3 supports and slides in the guide rail grooves 10.

[0031] Further, in the embodiment of the present invention, the lower surface of the lifting plate 3 is provided with a clamping mechanism for clamping and fixing the hub 14; specifically, the clamping mechanism includes a The support plates 11 on the lower surfaces of both sides, the electric telescopic rod 12 is fixedly installed on the support plate 11, and the clamping mechanism also includes a clamp block 13, and the clamp block 13 is fixedly installed on the telesc...

Embodiment 2

[0039] Such as figure 1 As shown, in the embodiment provided by the present invention, a new energy vehicle wheel hub grinding device includes a base 1, a bracket 2 is fixedly arranged on the base 1, and a bracket 2 for adjusting the lifting plate 3 is arranged on the top of the bracket 2. The lifting assembly at the height of the center; the inner walls of both sides of the support 2 are provided with guide rail grooves 10, and the end of the lifting plate 3 supports and slides in the guide rail grooves 10.

[0040] Further, in the embodiment of the present invention, the lower surface of the lifting plate 3 is provided with a clamping mechanism for clamping and fixing the hub 14; specifically, the clamping mechanism includes a The support plates 11 on the lower surfaces of both sides, the electric telescopic rod 12 is fixedly installed on the support plate 11, and the clamping mechanism also includes a clamp block 13, and the clamp block 13 is fixedly installed on the telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com