Slitting equipment for semiconductor ceramic capacitor chip production

A technology of ceramic capacitors and semiconductors, which is applied in the field of slitting equipment for the production of semiconductor ceramic capacitor chips. It can solve the problems of uneven surface cut by the slitting knife and affect the use of semiconductor ceramic capacitor chips, and achieve the effect of avoiding shaking and offset.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

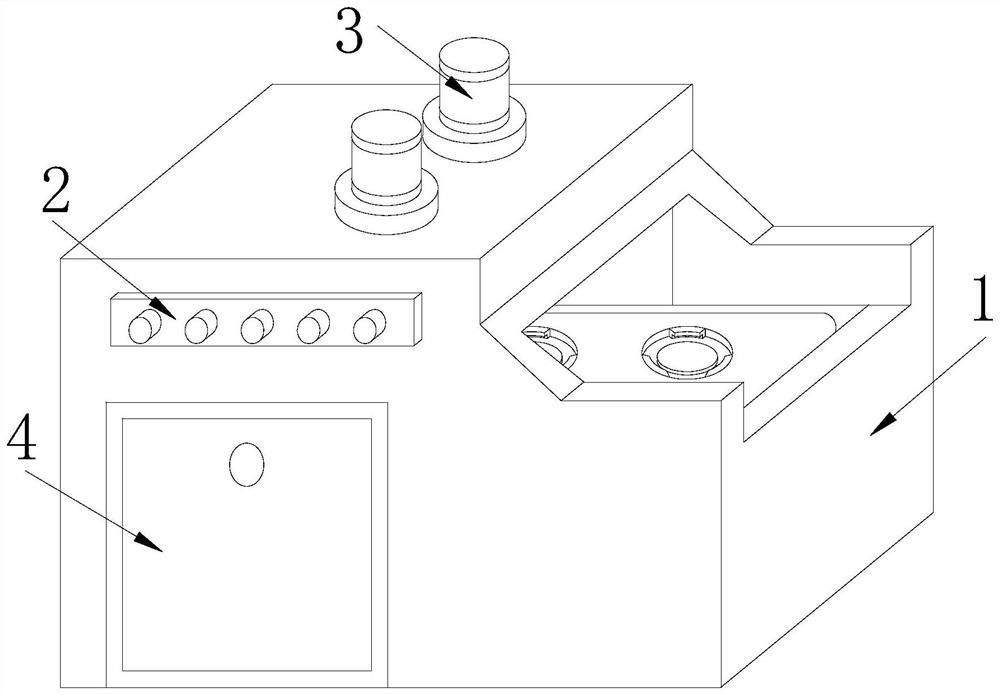

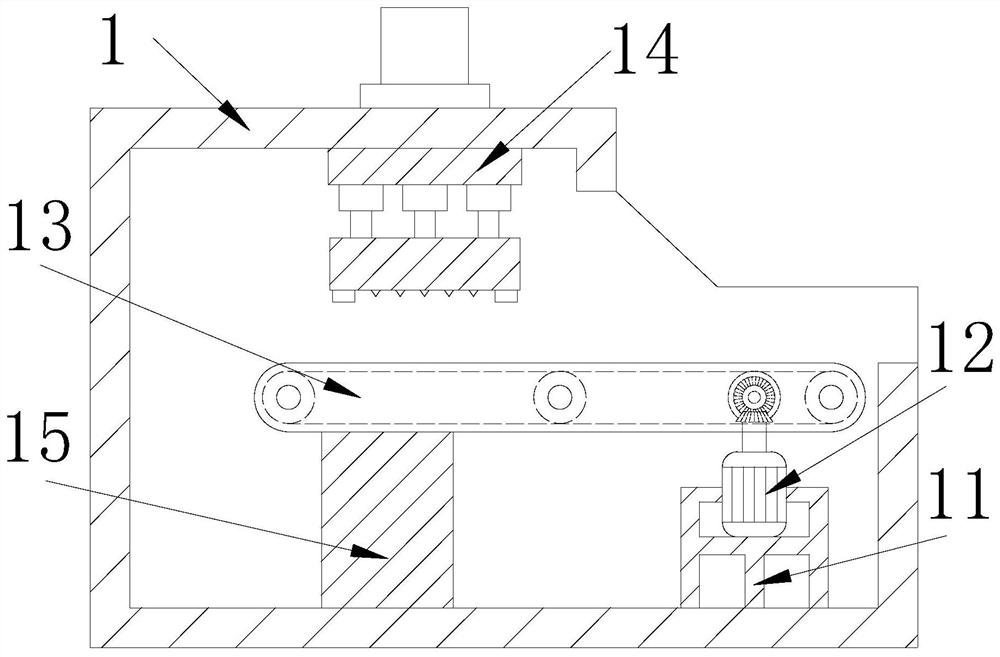

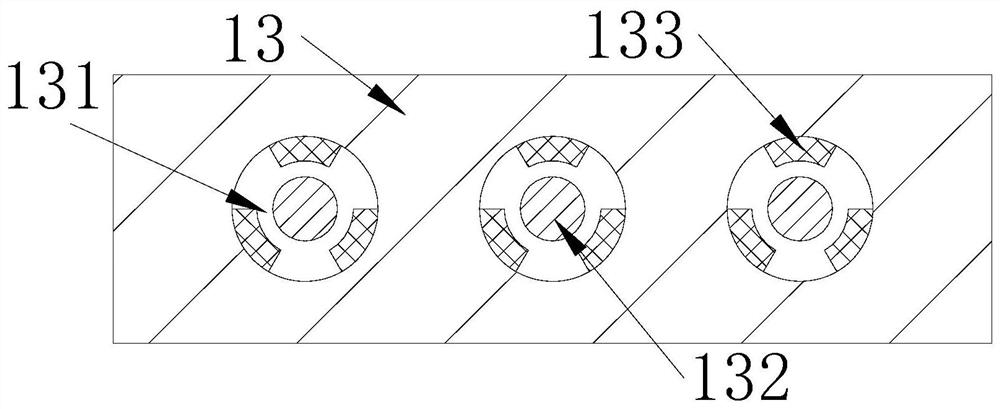

[0029] The present invention provides a cutting device for the production of semiconductor ceramic capacitor chips, the structure of which includes a cutting box 1, a controller 2, a cylinder 3, and a collecting box 4. The controller 2 is connected to the front side of the cutting box 1 by welding, The cylinder 3 is installed on the top of the slitting box 1, and the collection box 4 is connected to the front side of the slitting box 1 through movable engagement. The slitting box 1 includes a fixed frame 11, a driver 12, a pushing device 13, a cutting 14, a support block 15, the fixed frame 11 is embedded in the bottom of the slitting box 1, the driver 12 is mounted on the upper surface of the fixed frame 11, the pushing device 13 is connected to the end of the driver 12, and the splitter The top of the cutter 14 is embedded on the upper inner wall of the slitter box 1, and the cutter 14 is connected to the cylinder 3, the bottom end of the support block 15 is connected to the ...

Embodiment 2

[0035] The present invention provides a cutting device for the production of semiconductor ceramic capacitor chips, the structure of which includes a cutting box 1, a controller 2, a cylinder 3, and a collecting box 4. The controller 2 is connected to the front side of the cutting box 1 by welding, The cylinder 3 is installed on the top of the slitting box 1, and the collection box 4 is connected to the front side of the slitting box 1 through movable engagement. The slitting box 1 includes a fixed frame 11, a driver 12, a pushing device 13, a cutting 14, a support block 15, the fixed frame 11 is embedded in the bottom of the slitting box 1, the driver 12 is mounted on the upper surface of the fixed frame 11, the pushing device 13 is connected to the end of the driver 12, and the splitter The top of the cutter 14 is embedded on the upper inner wall of the slitter box 1, and the cutter 14 is connected to the cylinder 3, the bottom end of the support block 15 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com