Second piston member of brake master cylinder assembly

A technology for piston parts and brake master cylinders, which is applied in the direction of brakes, vehicle parts, brake transmissions, etc., can solve the problems of large number of assembly parts, many assembly links, and low assembly efficiency, so as to achieve high efficiency and reduce assembly Links, the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

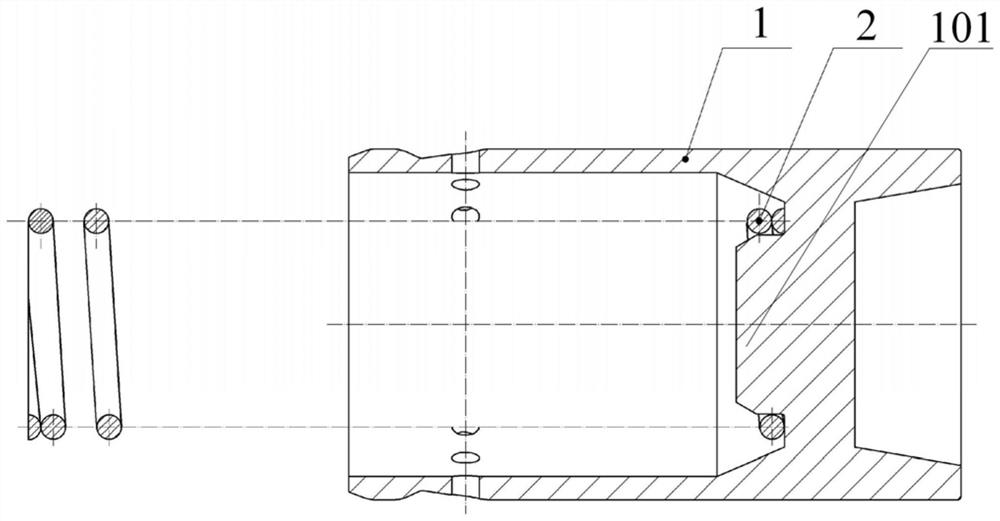

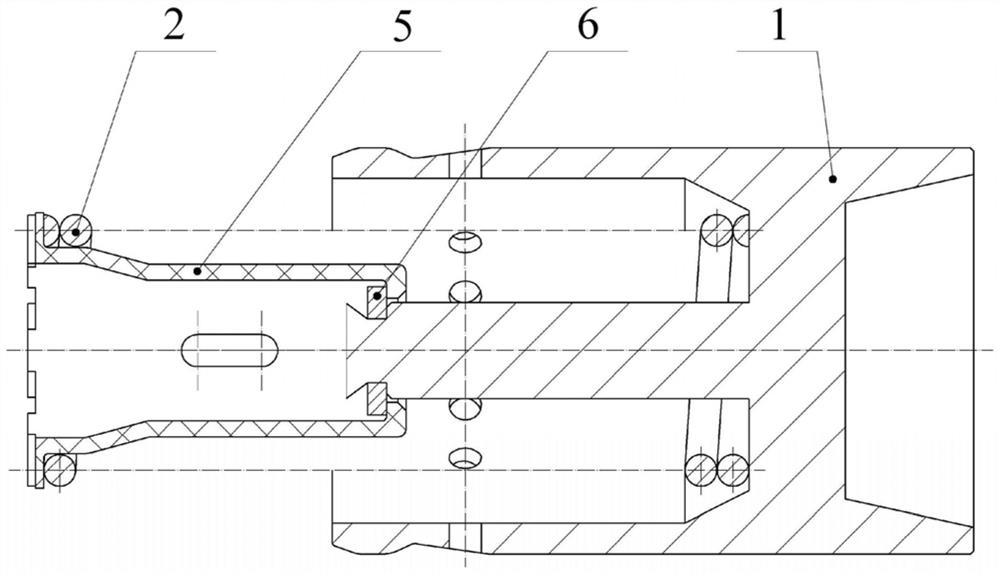

[0010] Such as figure 1 As shown, it consists of a second piston 1 and a second piston spring 2, wherein one end of the second piston spring 2 is interference fit with the boss 101 of the second piston 1 for axial positioning, and the other end of the second piston spring 2 It is used for clearance fit with the inner boss of the main cylinder body 3 bottom.

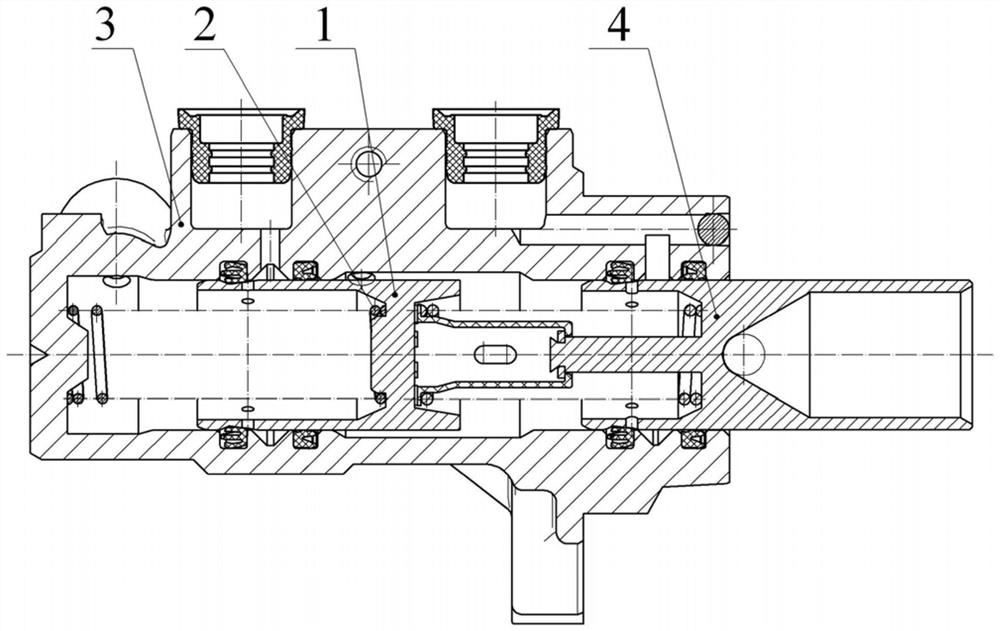

[0011] The present invention optimizes the structure of the joint between the second piston and the second piston spring, and determines that the technical solution is changed from the original clearance fit to the interference fit. figure 2 As shown, the clearance fit with the second piston spring realizes the axial limit, and the whole second piston part realizes the axial positioning under the action of the installation force of the booster transmitted from the first piston part 4, which satisfies the requirements of the brake master cylinder assembly. performance requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com