Conveying device for food processing

A conveying device and technology for food processing, applied in the field of conveying device and conveying equipment for food processing, can solve the problems of low processing efficiency, increase food processing procedures, lack of drying and flattening function, etc., so as to avoid pollution and improve food processing. Efficiency, effect of compressing food processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

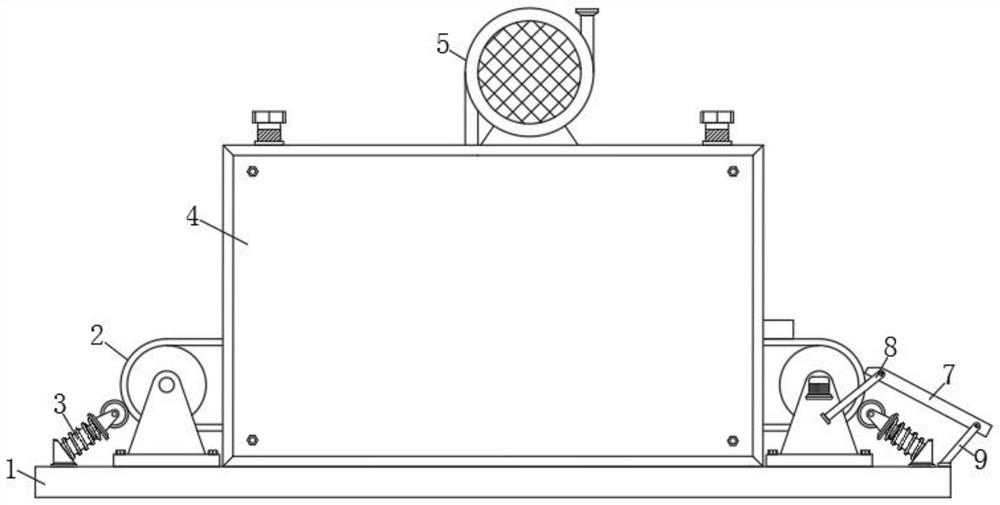

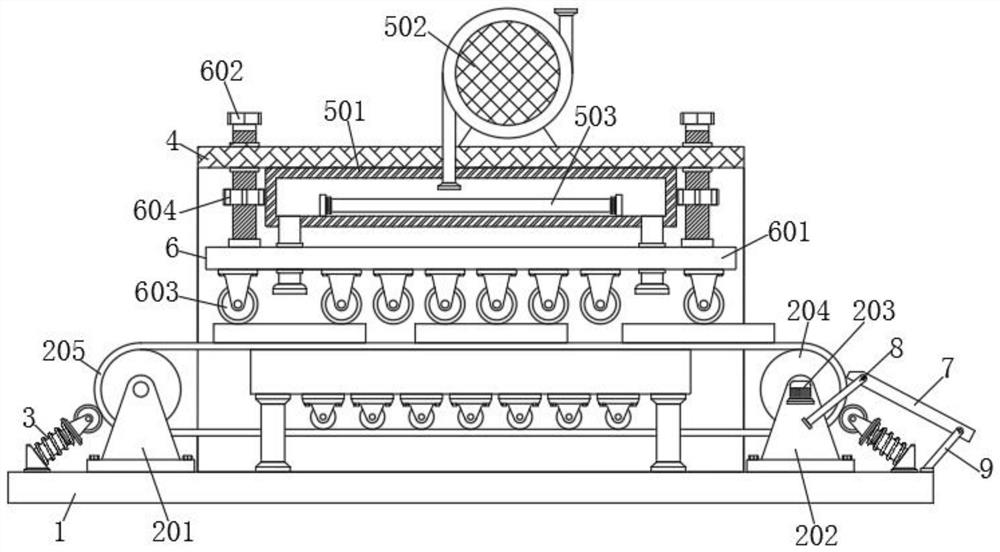

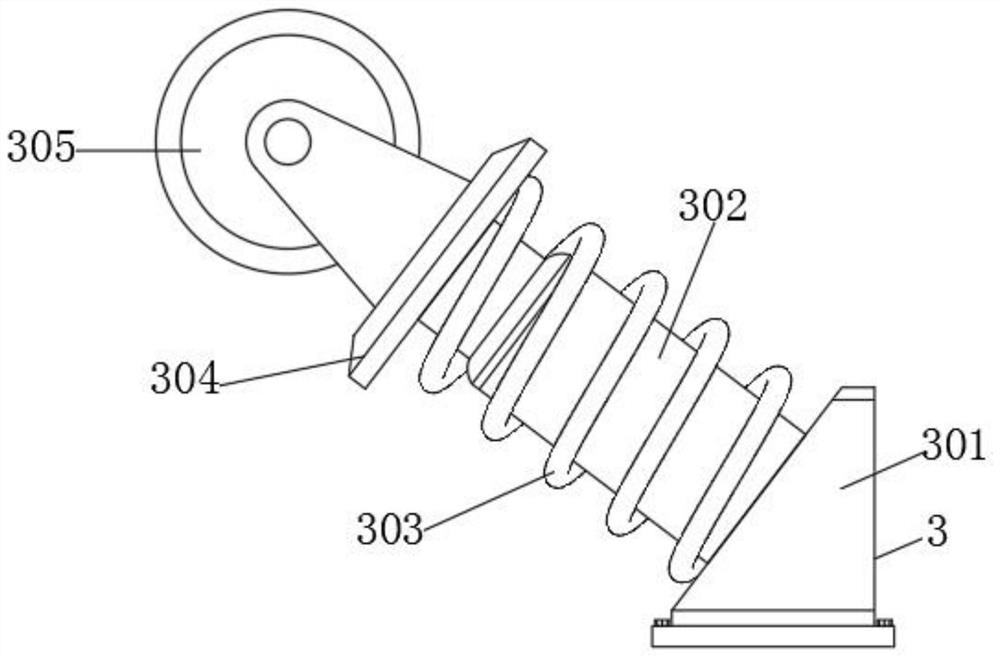

[0035] Such as Figure 1-4 As shown, a conveying device for food processing includes a working platform 1, a conveying mechanism 2 is arranged on the top of the working platform 1, and the conveying mechanism 2 is used for conveying food, and conveying food from one end of a conveying belt 205 to At the other end, two symmetrical cleaning mechanisms 3 are arranged on the top of the working platform 1. The cleaning mechanisms 3 are used to clean impurities and food residues on the surface of the conveying belt 205, so as to avoid contamination of the food that is subsequently transported. The cleaning mechanism 3 is respectively arranged on both sides of the conveying mechanism 2, the top of the working platform 1 is fixedly installed with an installation frame 4, and the inside of the installation frame 4 is provided with a hot air drying mechanism 5 and a flattening mechanism 6, and the hot air drying mechanism 5 is used for heating and drying the food on the conveyor belt 20...

Embodiment 2

[0047] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that four symmetrical support columns 10 are fixedly installed on the top surface of the working platform 1, and a backing plate 11 is fixedly installed between the tops of the four support columns 10, and the pads The top surface of the plate 11 fits with the bottom surface of the upper conveying belt 205, and the bottom surface of the backing plate 11 is provided with evenly distributed connecting seats 12, the bottom of the connecting seats 12 is provided with a cleaning cylinder 13, and the outer surface of the cleaning cylinder 13 is provided with uniform Distributed cleaning bristles 14, the cleaning bristles 14 are used to clean the inner surface of the conveying belt 205, avoiding impurities sticking to the inner surface of the conveying belt 205, causing a connection gap between the conveying belt 205 and the surface of the rotating roller 204, affecting the conveying belt 205...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com