A sulfur dioxide injection device for float glass annealing kiln

A sulfur dioxide and blowing device technology, which is applied in the field of float glass production, can solve the problems of glass quality degradation, high temperature at the outlet of the tin tank, and polluted tin liquid, etc., and achieve the effects of improving quality, protecting corrosion, and facilitating transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

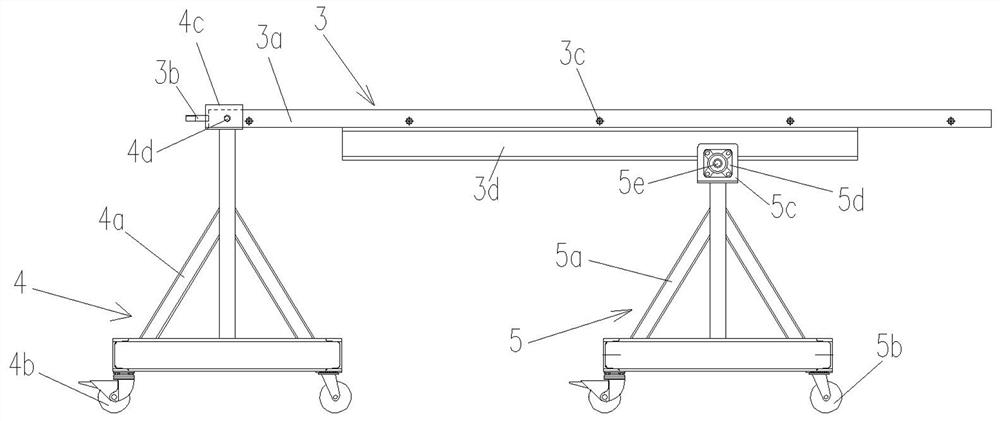

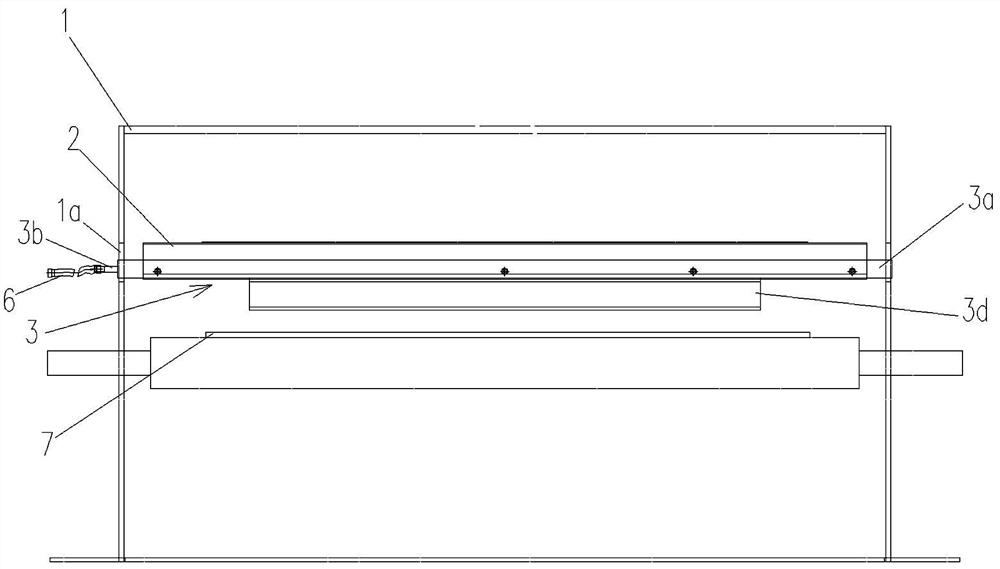

[0015] like Figure 1-3 As shown, a sulfur dioxide injection device for a float glass annealing kiln includes an annealing kiln 1, and a rail 2 distributed along the width direction of the annealing kiln 1 is welded to the top of the steel structure at a distance of 3000-3300 mm from the front end of the annealing kiln 1. Both ends of the rail 2 correspond to the operation holes 1a on both sides of the inlet end of the annealing kiln 1 .

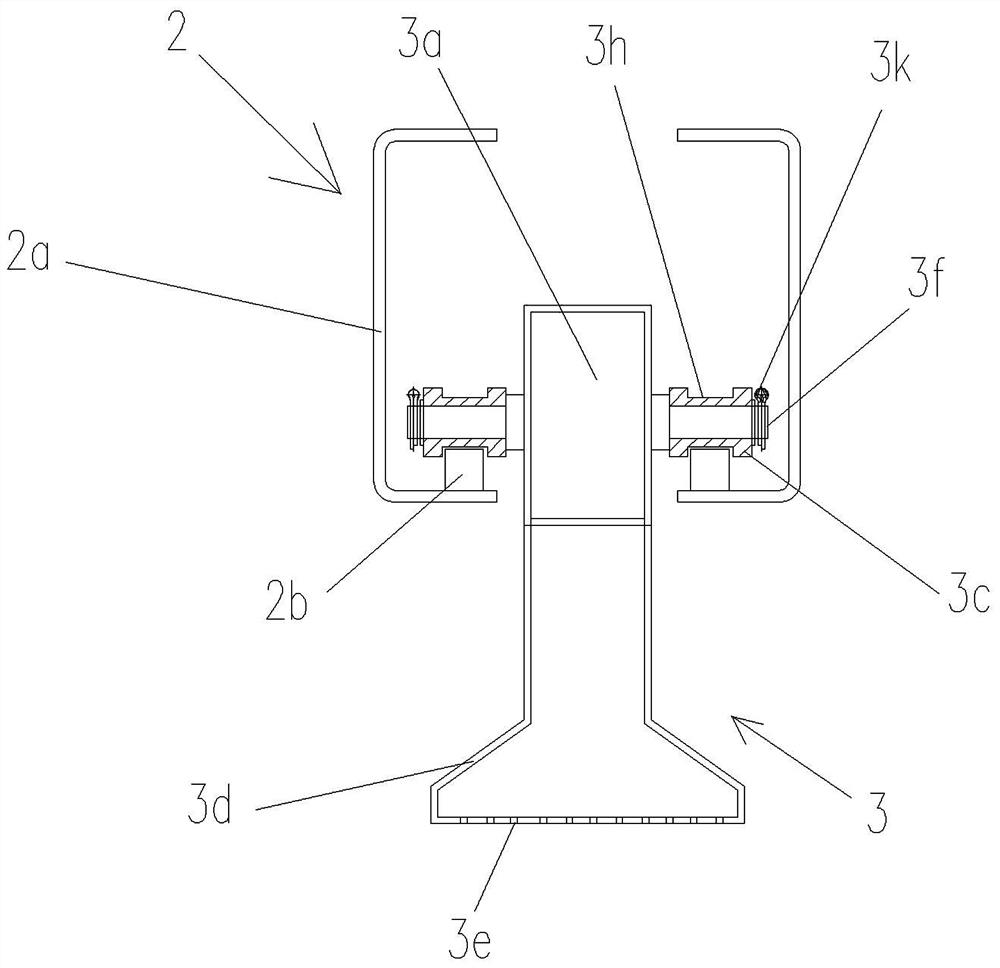

[0016] The track 2 includes two C-shaped channel steels 2a distributed along the width direction of the annealing kiln 1. The two channel steels 2a are relatively distributed, and there is a certain distance between the two channel steels 2a. Slideways 2b distributed along the axial direction are welded on the channel walls on one side of the two channel steels 2a.

[0017] A sprinkler 3 that can be inserted into the track 2 is provided. The sprinkler 3 includes a rectangular tubular main body 3a, two ends of the main body 3a are sealed str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com