Hard PVC plastic high-impact modifier and preparation method thereof

A technology of high impact resistance and modifier, applied in the field of polymer materials, can solve the problems of limited application range and limited effect, and achieve the effect of increasing Vicat softening temperature, improving impact strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

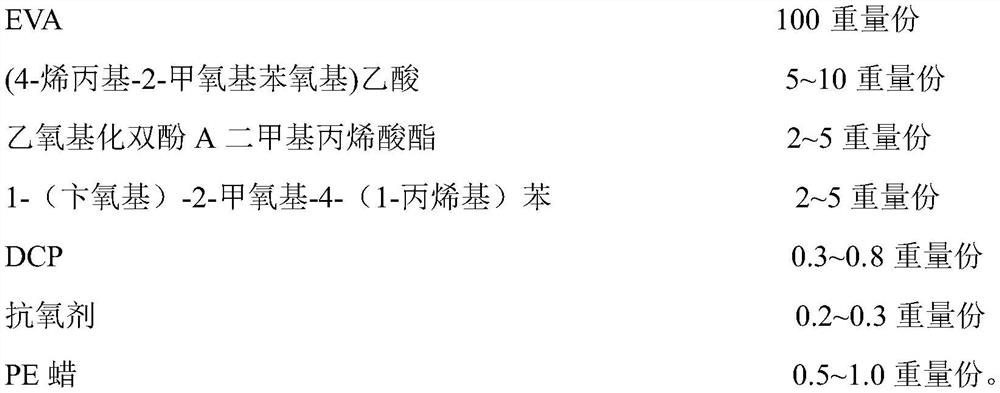

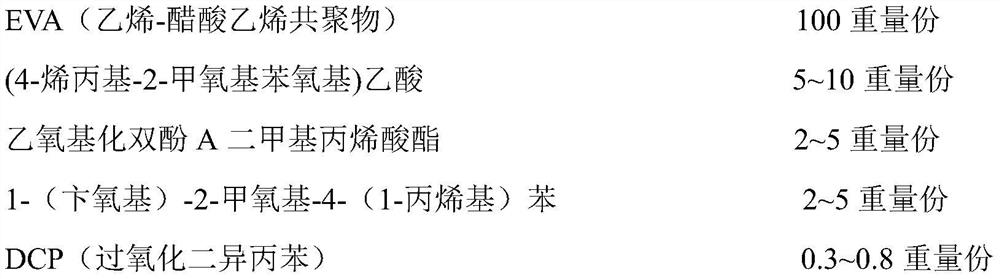

[0025] formula:

[0026]

[0027] Preparation:

[0028] (1) Extrude on a twin-screw extruder with an aspect ratio of L / D=48. The twin-screw extruder has 12 sections and 3 feed ports. The first feed port is located at the first of the extruder. Sections, the second feed port is located in the fifth section of the extruder, and the third feed port is located in the seventh section of the extruder;

[0029] (2) EVA is added with 75kg / h feed speed to the first feed inlet that the twin-screw extruder with 110r / min operating speed is located.

[0030] (3) Add (4-allyl-2-methoxyphenoxy)acetic acid, ethoxylated bisphenol A dimethacrylate, 1-(Bianoxy)-2-methoxy-4 -(1-propenyl)benzene, DCP, after mixing evenly according to the formula ratio, under the pressure of 0.8 ~ 1.2MPa, add the second feed port located on the twin-screw extruder at a feed rate of 6.5kg / h, EVA molecule The grafting reaction on the chain then occurs, and the processing temperature of the extruder gradually in...

Embodiment 2

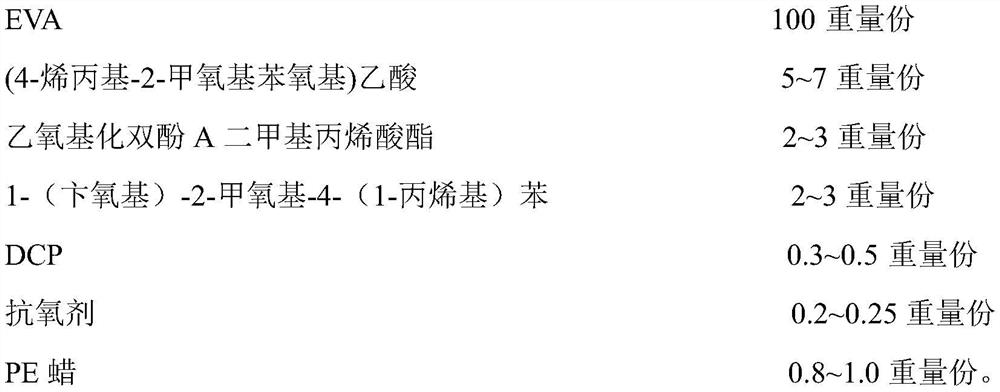

[0034] formula:

[0035]

[0036] Preparation:

[0037] (1) Extrude on a twin-screw extruder with an aspect ratio of L / D=48. The twin-screw extruder has 12 sections and 3 feed ports. The first feed port is located at the first of the extruder. Sections, the second feed port is located in the fifth section of the extruder, and the third feed port is located in the seventh section of the extruder;

[0038] (2) EVA is added with 75kg / h feed speed to the first feed inlet that the twin-screw extruder with 110r / min operating speed is located.

[0039] (3) Add (4-allyl-2-methoxyphenoxy)acetic acid, ethoxylated bisphenol A dimethacrylate, 1-(Bianoxy)-2-methoxy-4 -(1-propenyl)benzene, DCP, after mixing evenly according to the formula ratio, under the pressure of 0.8 ~ 1.2MPa, add the second feed port located on the twin-screw extruder at a feed rate of 6.5kg / h, EVA molecule The grafting reaction on the chain then occurs, and the processing temperature of the extruder gradually in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com