Laser marking shading enhanced PBT composition as well as preparation method and application thereof

A technology of laser marking and composition, which is applied in the field of engineering plastics, can solve the problems of expensive laser marking materials and cannot be mass-produced, and achieve improved laser marking performance and shading effect, improved contrast, and clear laser marking. Effect

Active Publication Date: 2021-02-19

KINGFA SCI & TECH CO LTD

View PDF8 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to overcome the defects of expensive laser marking materials in the prior art and cannot be mass-produced, and to provide a laser marking light-shielding enhanced PBT composition, which has both laser marking and light-shielding effects

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

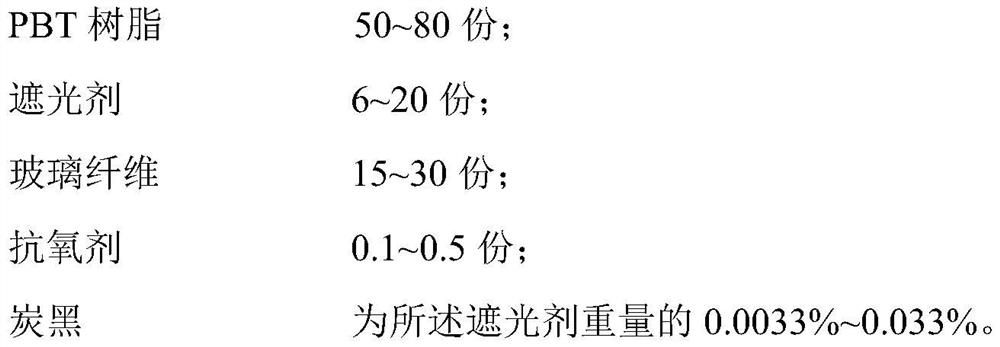

Embodiment 1~4

[0049] Table 1 Embodiment 1~4PBT composition each component content

[0050]

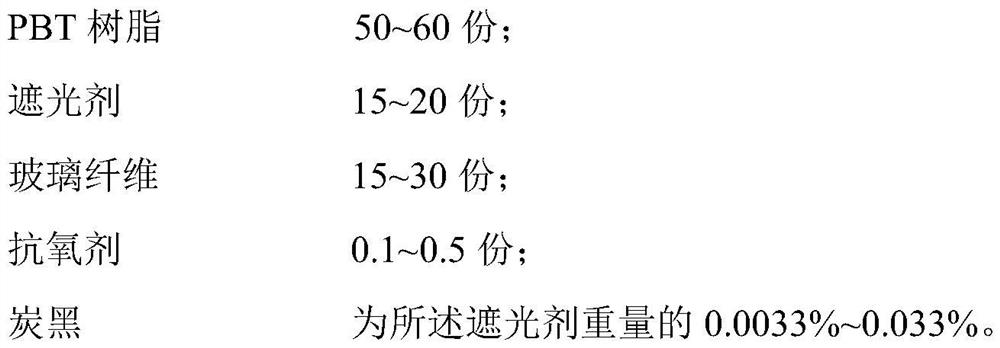

Embodiment 5~8

[0051] The content of each component of the PBT composition of table 2 embodiment 5~8

[0052]

Embodiment 9~12

[0053] Table 3 Embodiment 9~12PBT composition each component content

[0054]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a laser marking shading enhanced PBT composition. The composition comprises the following components in parts by weight: 50-80 parts of PBT resin; 6-20 parts of an opacifying agent; 15-30 parts of glass fiber; 0.1-0.5 part of antioxidant; and carbon black accounting for 0.0033%-0.033% of the weight of the opacifying agent. Under the condition that no expensive laser markingagent is used and only the opacifying agent and the trace carbon black are compounded, the composition has the following properties that: a shading effect of which the whiteness value is larger than 90 and of which the thickness is smaller than 3 mm is achieved; and the color difference value before and after laser marking is larger than 15; and therefore, composition can be applied to the field of preparation of lamp cup shells, capacitors, connectors or relay products in the lighting industry.

Description

technical field [0001] The invention relates to the technical field of engineering plastics, more specifically, to a laser marking light-shielding reinforced PBT composition used in the lighting industry and a preparation method and application thereof. Background technique [0002] Polybutylene terephthalate (PBT) is a translucent to opaque milky white crystalline thermoplastic polyester, one of the important members of the five major engineering plastics, PBT is often used in the lamp cup housing in the lighting industry. The performance requirements of the lamp cup shell usually include flame retardancy, thermal shock cycle, light shading, laser marking, heat resistance, etc. At present, the method to solve the shading performance is mainly to add a large amount of shading agent, and the method to solve the laser marking performance is mainly to add a laser marking agent, but the laser marking agent is expensive, and it is difficult to obtain a low-cost product with good ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L67/02C08K3/22C08K7/14C08K3/04C08K5/134C08K13/04

CPCC08K3/22C08K7/14C08K3/04C08K5/1345C08K13/04C08K2003/2241C08L67/02B29B7/48B29B7/88B29B7/90B29B7/726B29B9/06B29B9/14B29B7/82C08K2201/003C08K2201/004C08K2201/001C08K3/2279C08K2003/3036C08K5/005B29B7/46B29B7/38C08J3/203C08J7/123C08J2367/02C08K5/13C08K2201/014

Inventor 莫文杰黄险波叶南飚朱文龚德君冯健付学俊

Owner KINGFA SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com