High-adhesion, static-conductive water-based reflective heat-insulating coating for storage tanks and preparation method thereof

A technology of reflective heat-insulating coatings and high adhesion, which is applied in conductive coatings, reflective/signal coatings, coatings, etc. It can solve problems such as unsatisfactory adhesion and affecting coating weather resistance, so as to improve service life and increase anchorage point, increase the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A high-adhesion, static-conductive water-based reflective heat-insulating coating for chemical storage tanks, including a high-adhesion reflective heat-insulation coating and a static-conductive reflective coating;

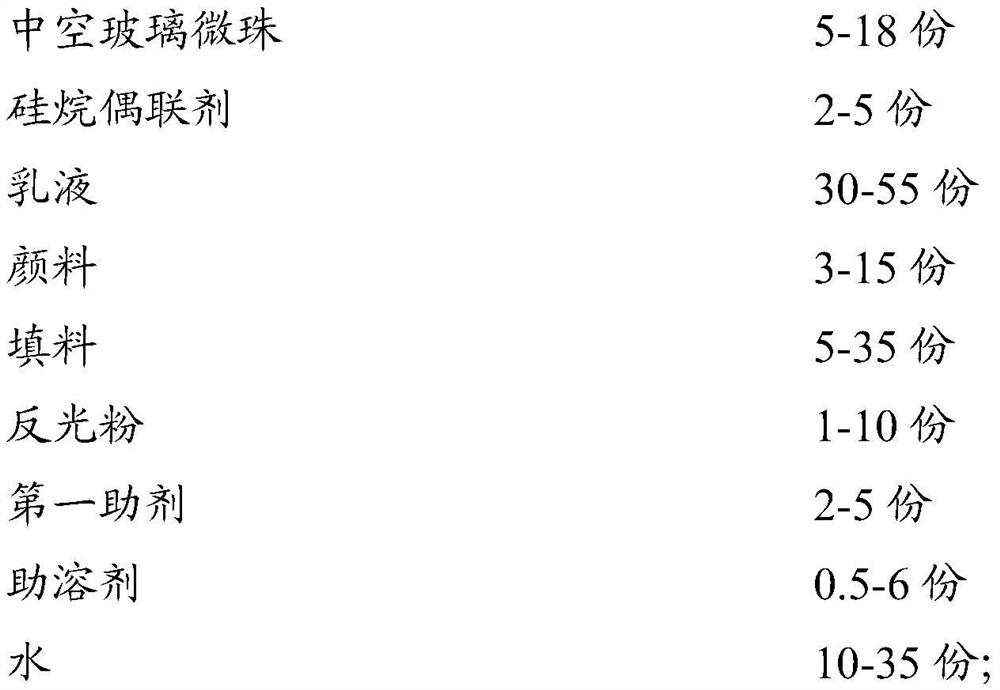

[0057] The high-adhesion reflective heat-insulating coating consists of the following components in parts by weight:

[0058]

[0059] The electrostatically conductive reflective coating is composed of the following components in parts by weight:

[0060]

[0061] The first auxiliary agent is a commercially available dispersant, wetting agent, defoamer, leveling agent, thickener, multifunctional auxiliary agent, bactericide and light stabilizer commonly used in the art;

[0062] The second auxiliary agent is commercially available film-forming auxiliary agent, defoamer, thickener, cosolvent and bactericide commonly used in this field.

[0063] The preparation method of the above-mentioned high-adhesion reflective heat-insulating coating is:

[0064]...

Embodiment 2

[0077] A high-adhesion, static-conductive water-based reflective heat-insulating coating for chemical storage tanks, including a high-adhesion reflective heat-insulation coating and a static-conductive reflective coating;

[0078] The high-adhesion reflective heat-insulating coating consists of the following components in parts by weight:

[0079]

[0080]

[0081] The electrostatically conductive reflective coating is composed of the following components in parts by weight:

[0082]

[0083] The preparation method of above-mentioned high-adhesion reflective heat-insulating paint is the same as embodiment 1;

[0084] The preparation method of above-mentioned conductive static reflection coating is the same as embodiment 1;

[0085] The construction method of the above-mentioned chemical storage tank with high adhesion and static conductive water-based reflective heat insulation coating, the same

[0086] Example 1.

Embodiment 3

[0088] A high-adhesion, static-conductive water-based reflective heat-insulating coating for chemical storage tanks, including a high-adhesion reflective heat-insulation coating and a static-conductive reflective coating;

[0089] The high-adhesion reflective heat-insulating coating consists of the following components in parts by weight:

[0090]

[0091]

[0092] The electrostatically conductive reflective coating is composed of the following components in parts by weight:

[0093]

[0094] The preparation method of above-mentioned high-adhesion reflective heat-insulating paint is the same as embodiment 1;

[0095] The preparation method of above-mentioned conductive static reflection coating is the same as embodiment 1;

[0096] The construction method of the above-mentioned chemical storage tank with high adhesion and static conductive water-based reflective heat insulation coating, the same

[0097] Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com