Steel-concrete composite continuous beam, connecting piece of hogging moment area of steel-concrete composite continuous beam and construction method

A technology of negative bending moment zone and connector, applied in the direction of bridge parts, bridges, building components, etc., can solve the problems of corrosion of low elastic modulus materials, weakening transverse shear resistance, affecting the crack resistance of concrete roofs, etc. Convenience and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

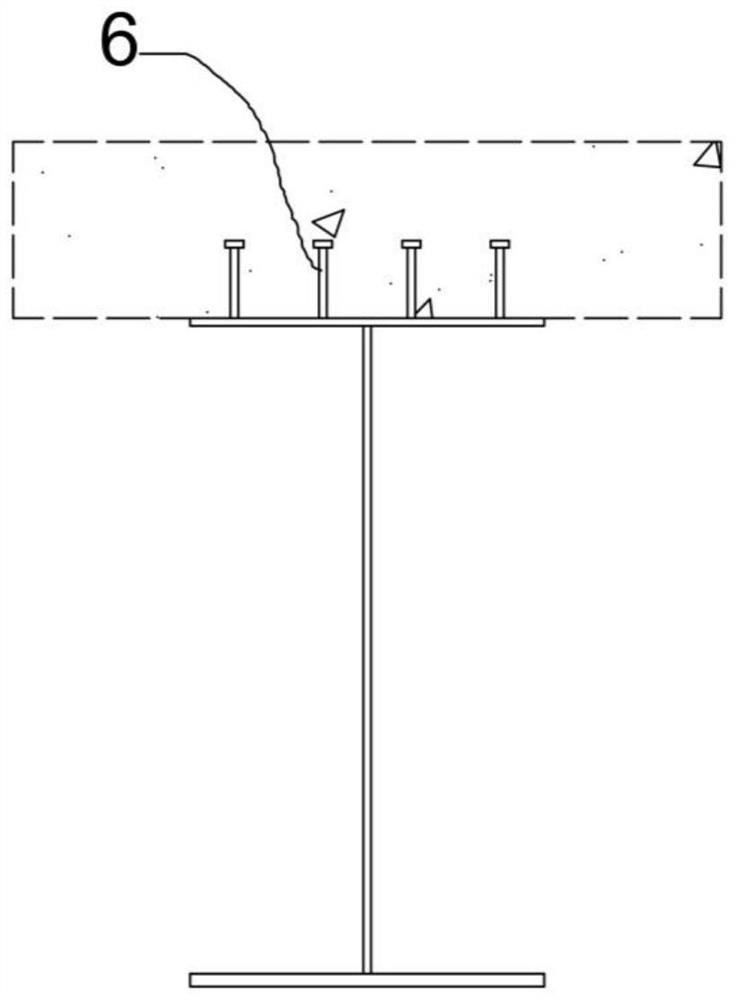

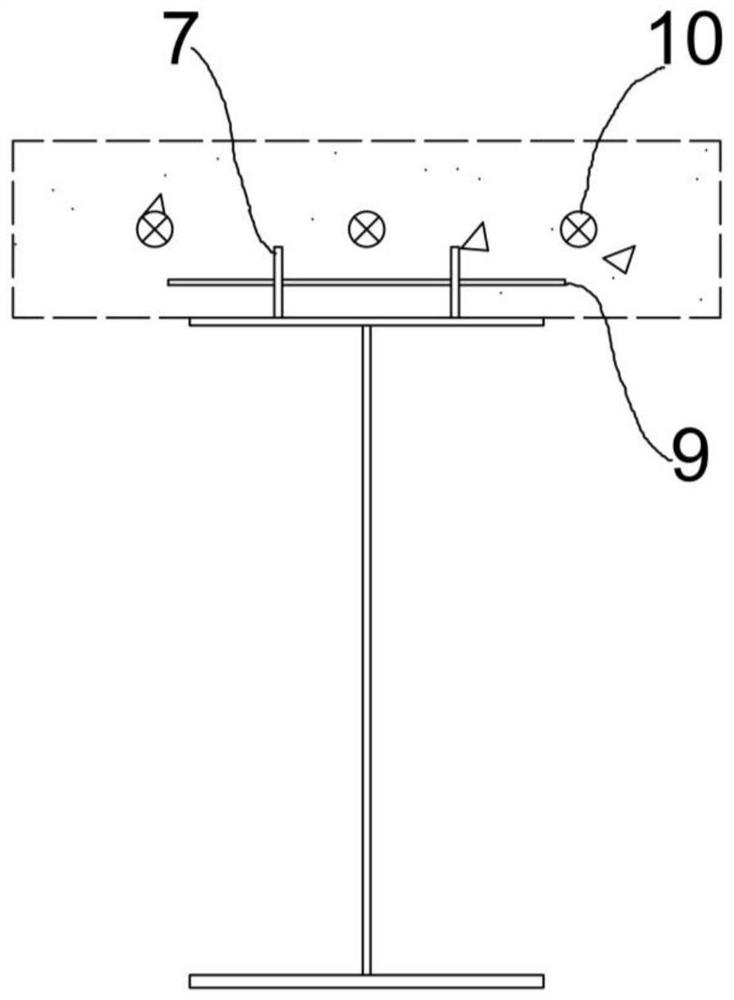

[0049] Such as figure 1 As shown, a connector suitable for the negative moment zone of steel-concrete composite continuous beams is disclosed. , including perforated plate 7, transverse reinforcement 9 and foam filling material 8; where:

[0050] The lower end surface of the perforated plate 7 can be welded and fixed to the top plate of the steel beam 4 in the negative moment zone, and the length extension direction of the perforated plate 7 is parallel to the direction along the bridge, and the perforated plate 7 is along its own The length extension direction is provided with a row of oval holes, the row of oval holes includes more than one oval hole, and the major axis direction of each oval hole is parallel to the length extension direction of the perforated plate 7;

[0051] The number of the transverse reinforcing bars 9 is consistent with the quantity of the oval holes; the length extension direction of each transverse reinforcing bar 9 is parallel to the transverse br...

Embodiment 2

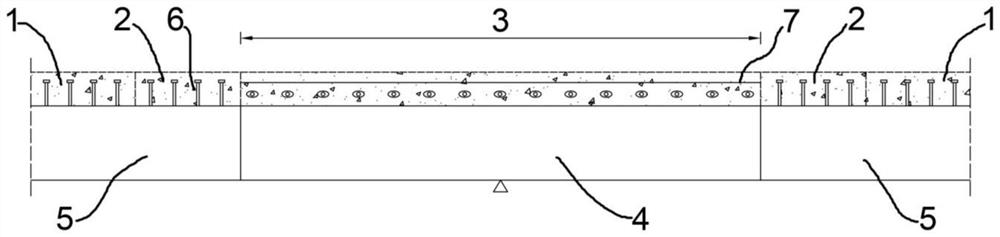

[0058] Such as Figure 1 to Figure 7 As shown, a steel-concrete composite continuous beam is disclosed, which includes the pull-out and non-shear open-hole plate connector described in Embodiment 1, specifically, the steel-concrete composite continuous beam includes steel beams, bolts Nail connectors 6, perforated plates 7, transverse steel bars 9, prestressed tendons 10 and concrete top slabs. The steel beams are divided into steel beams 4 in the negative bending moment area and steel beams 5 in the positive bending moment area. The steel girder 4 in the bending moment zone is located at both ends of the bridge along the direction of the bridge. The concrete roof is divided into the concrete roof 3 in the negative bending moment area, the concrete roof 1 in the positive bending moment area, and the reserved groove preset on the concrete roof 1 in the positive bending moment area, and the negative bending moment area is poured on the steel beam 4 roof in the negative bending ...

Embodiment 3

[0065] This embodiment provides a construction method for a steel-concrete continuous composite beam using the above-mentioned pullout-resistant and non-slip-resistant perforated plate connector, and the specific steps include:

[0066] First, prefabricate the steel beam 5 in the positive moment zone and the steel beam 4 in the negative moment zone by selecting appropriate steel materials according to the environment, and weld the perforated plate 7 on the top plate of the steel beam 4 in the negative moment zone, and weld the steel beam 4 in the positive moment zone 5. Weld the stud connector 6 on the upper surface of the top plate.

[0067] Set up temporary buttresses at the construction site, erect steel beams 5 in the positive moment area and steel beams 4 in the negative moment area, and weld the joints of adjacent beams together.

[0068] After being closed, foam 8 is inserted into the opening of the perforated plate 7, and the transverse steel bar 9 is penetrated to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com