Structure for increasing torsion angle of shock absorber

A technology of torsion angle and shock absorber, applied in the direction of spring/shock absorber, clutch, friction clutch, etc., can solve the problems of small torsion angle of shock absorber, difficult parts processing, low production efficiency of parts, etc. Difficulty, improve production efficiency, improve the effect of parts strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

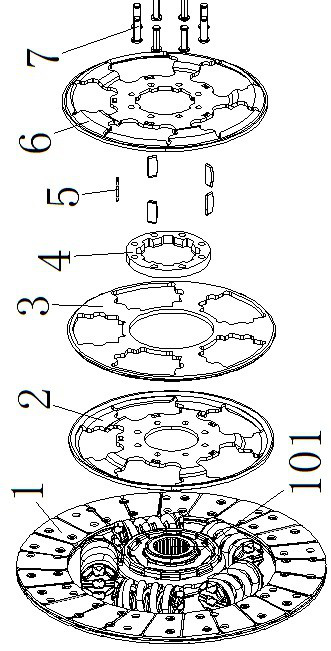

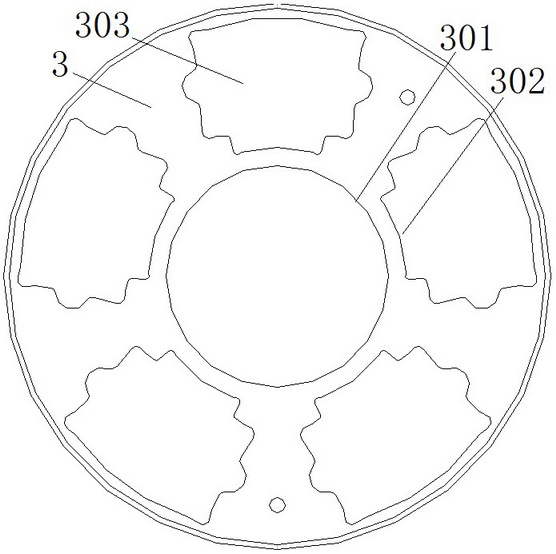

[0021] The present invention comprises clutch other assembly 1, rivet 7, and clutch other assembly 1 is other parts except improved parts on the clutch, and rivet 7 is the effect that each part before improvement and after improvement is connected together. Improve the left shock absorbing disc 2 and the right damping disc 6, the driven disc 3, the outer disc hub 4 and install the left damping disc 2 and the right damping disc 6, the driven disc 3, the outer disc hub 4 or The spacer block 5 of spacing; the improved structure of the left damping disc 2 and the right damping disc 6 is exactly the same, and they correspond to each other, and they are placed on both sides of the driven disc 3 and the outer disc hub 4 respectively during installation.

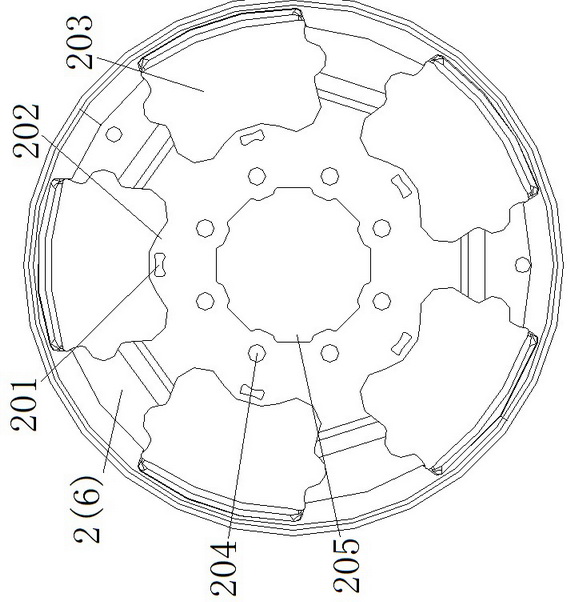

[0022] Left damping disc 2 or right damping disc 6: there is a protrusion 202 near the center side of the window 203 of the damping disc, and a limit block mounting hole 201 is opened on the protrusion 202 . The window opening of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com