Building construction dust removal device

A technology for dust removal device and building construction, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators, etc., can solve the problems of inability to further improve the dust removal effect of the device, reduce the range of dust removal, and affect the range of dust removal by the device, etc. To achieve the effect of increasing the range of sprayed water mist and improving the dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

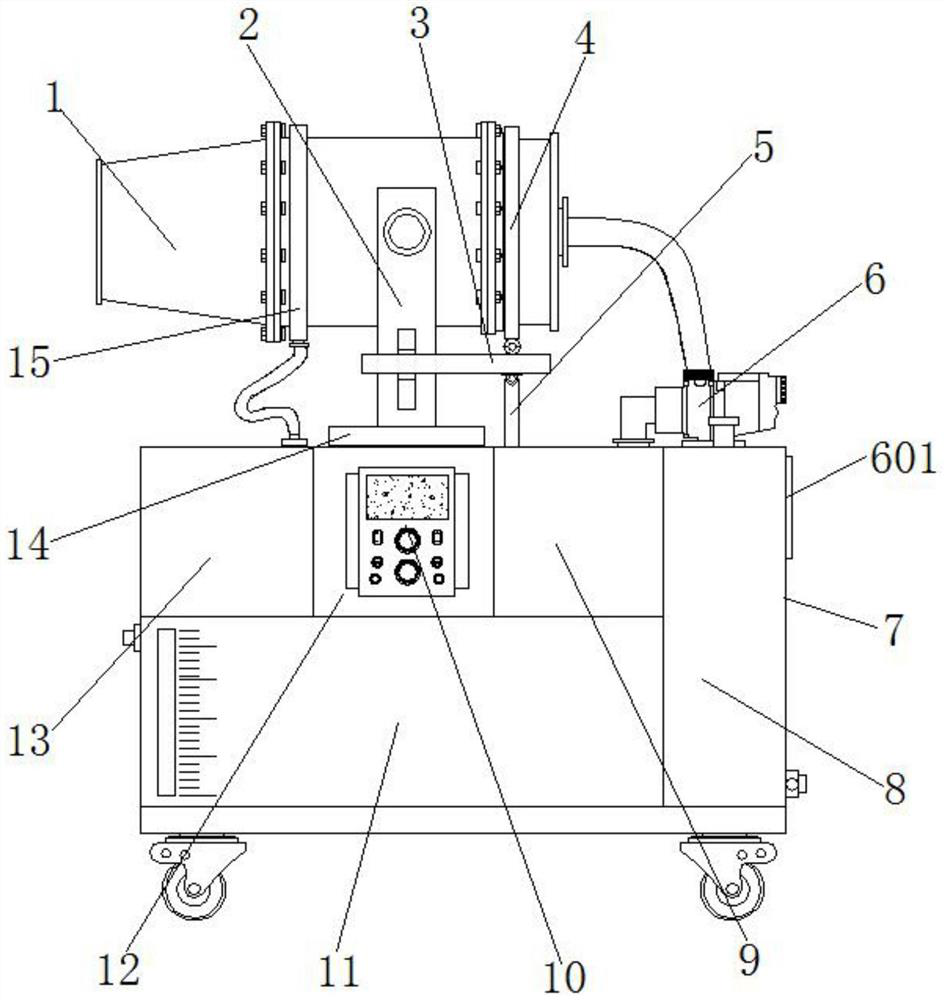

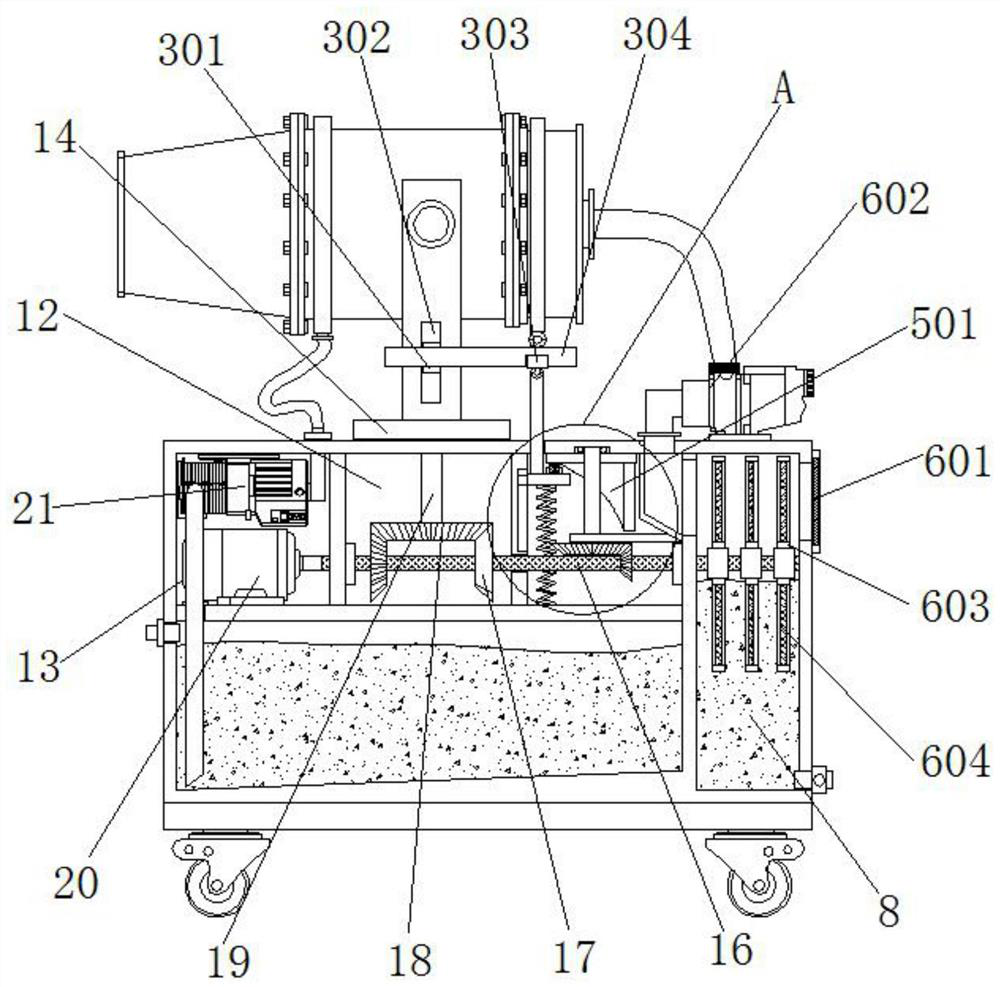

[0036] Example 1, such as figure 1 , 2 As shown in and 4, when the spraying gun barrel 1 is required to swing back and forth horizontally, the driving motor 20 is used to drive the driving shaft 16 to rotate, and the driving shaft 16 drives two groups of first bevel gears 17 to rotate, and the first group of first bevel gears 17 meshes with the second bevel gear 18 to drive the rotating rod 19 and the rotating disk 14 to rotate clockwise, the first bevel gear 17 of the second group does not mesh with the second bevel gear 18, and the first bevel gear 17 of the second group When meshing with the second bevel gear 18, it will drive the rotating rod 19 and the turntable 14 to rotate counterclockwise, thereby driving the U-shaped frame 2 and the spraying barrel 1 to swing back and forth horizontally, so that the sprayed out of the spraying barrel 1 The water mist can be sprayed in different horizontal directions to improve the spraying range of the water mist.

Embodiment 2

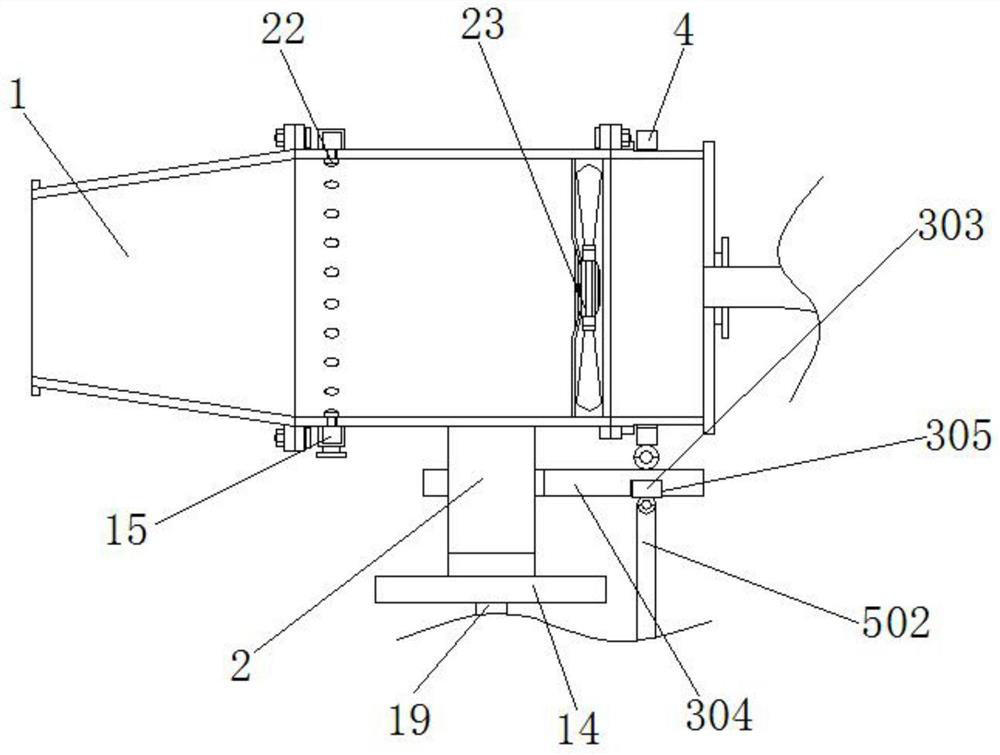

[0037] Example 2, such as figure 1 , 2 , 3, 5, 7 and 8, when the spray gun barrel 1 needs to be continuously changed in the process of swinging back and forth in the level, the drive shaft 16 is used to drive the small bevel gear 506 to rotate, and the small bevel gear 506 passes through and The large bevel gear 507 cooperates to drive the rotation shaft 504 to rotate, thereby driving the adjustment ring 501 to rotate. During the rotation of the adjustment ring 501, the cooperation between the adjustment ring 501 and the roller 503 is used to force the lifting plate 505 to continuously rise and fall, and the spring 508 is continuously shortened. Re-extended again, lifting plate 505 lifts and lifts connecting rod 502 to lift, and utilizes connecting rod 502 to pull U-shaped plate 304 to lift, thereby pulling the end of spray gun barrel 1 close to dust filter chamber 8 through collar 4 and gradually tilting downward. The collar 4 gradually slides on the outside of the spray bar...

Embodiment 3

[0038] Example 3, such as figure 1 , 2 As shown in and 6, before the outside air enters the inside of the spray gun barrel 1, the outside air first passes through multiple sets of rotating filter screens 604, and the dust in the air is filtered and blocked by the water-soaked filter screen 604 and the dust is adsorbed on the surface of the filter screen 604 , and when the dust-attached part of the filter screen 604 enters the clean water inside the dust filter chamber 8 due to rotation, the attached dust will fall off into the clean water again, and the rotating filter screen 604 is constantly used to filter the air entering the spray gun barrel 1. Purification treatment in advance, combined with the sprayed water mist inside the spray gun barrel 1, can greatly improve the dust removal effect of the device.

[0039] Working principle: Connect the device to the power supply before use, then use the universal wheels to move the device to the designated position, and then turn o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com