Automatic dust removal device, dust removal system and dust removal method based on intelligent analysis

An automatic dust removal and intelligent analysis technology, which is applied in separation methods, measuring devices, particle suspension analysis, etc., can solve problems such as endangering workers' bodies, incapable of portrait recognition, and inability to apply to factories, etc., to achieve the effect of expanding the scope of dust removal and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

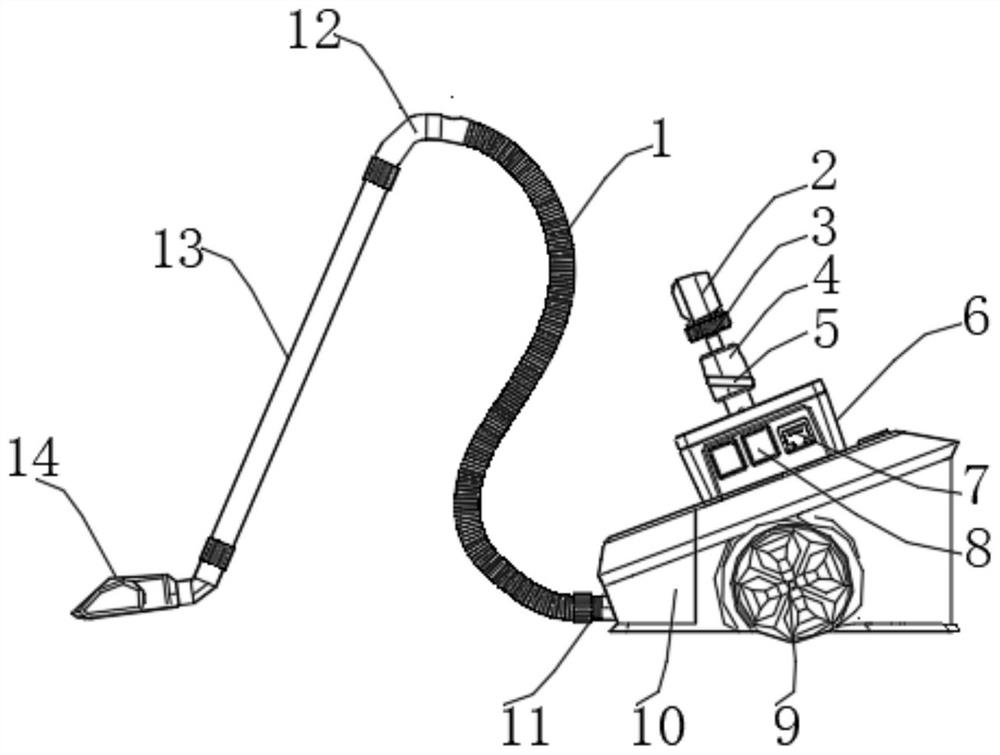

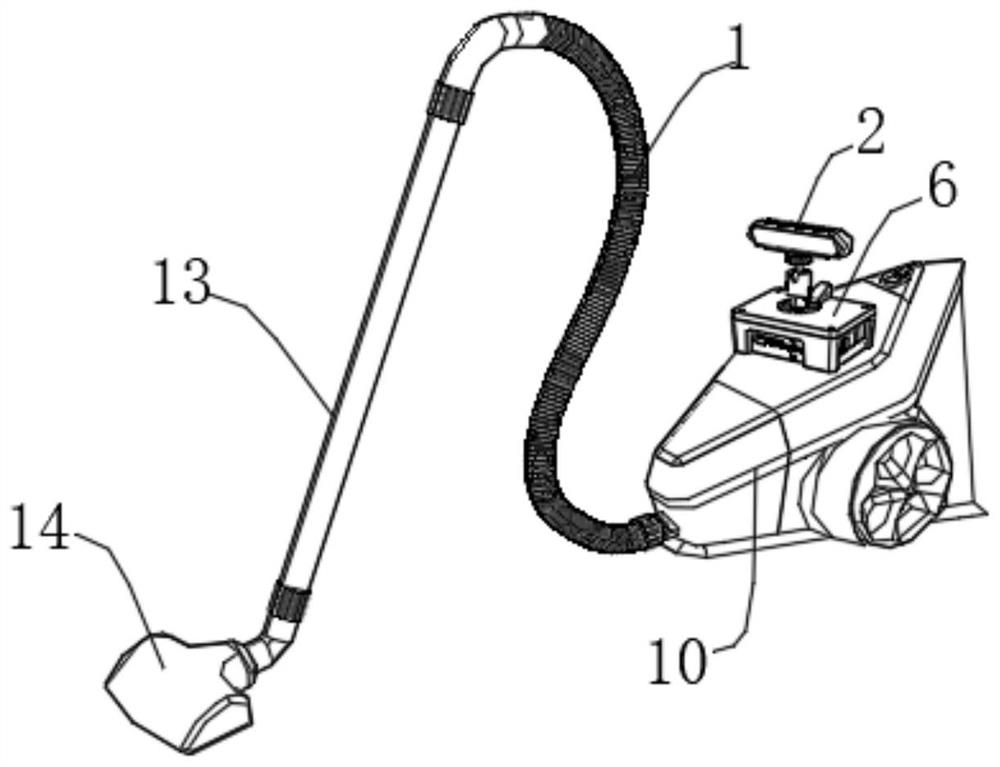

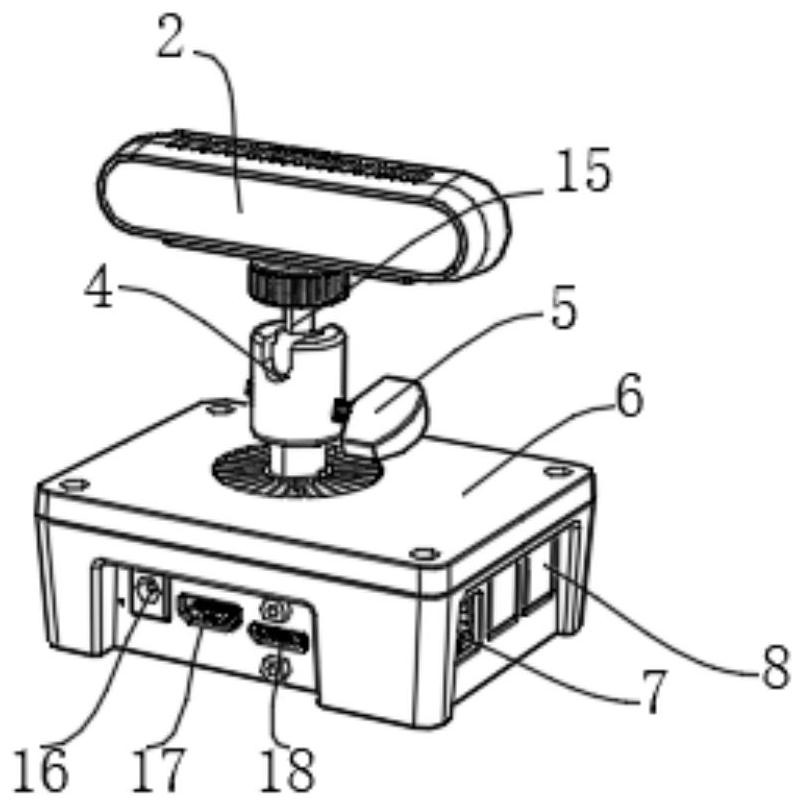

[0038] The applicant believes that the size of traditional dust removal devices used in factories occupies a large area, the dust removal range is limited, and the current dust collectors are relatively low in intelligence. In an environment with a large amount of dust, workers need to manually operate the machine to open and Monitoring the air quality index in the factory building at any time not only increases the work intensity of the workers, but also endangers the workers' health at all times, and the traditional dust collector cannot perform regular self-dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com