Coating workshop waste gas treatment device

A technology for treating device and workshop waste gas, applied in the field of spraying and processing, can solve the problems of incapable of secondary filtration of waste gas, single filtration and purification, low efficiency, etc., and achieve the effect of improving the use effect, good filtering effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

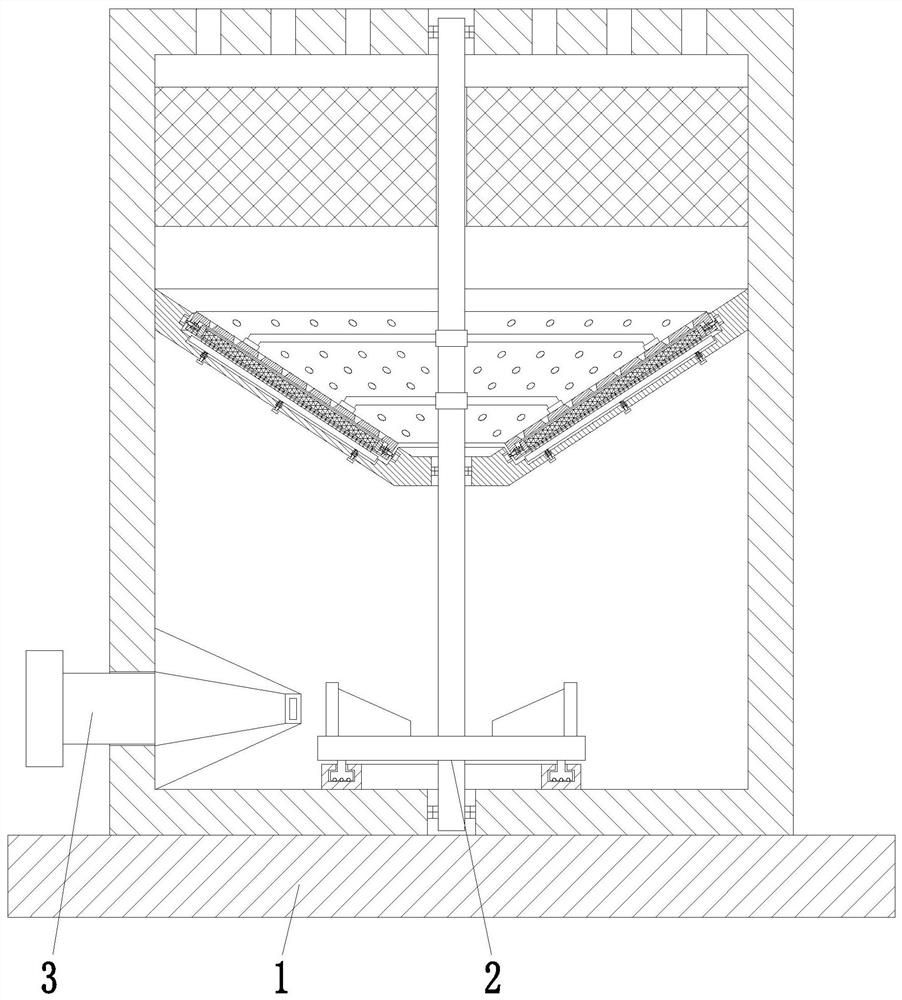

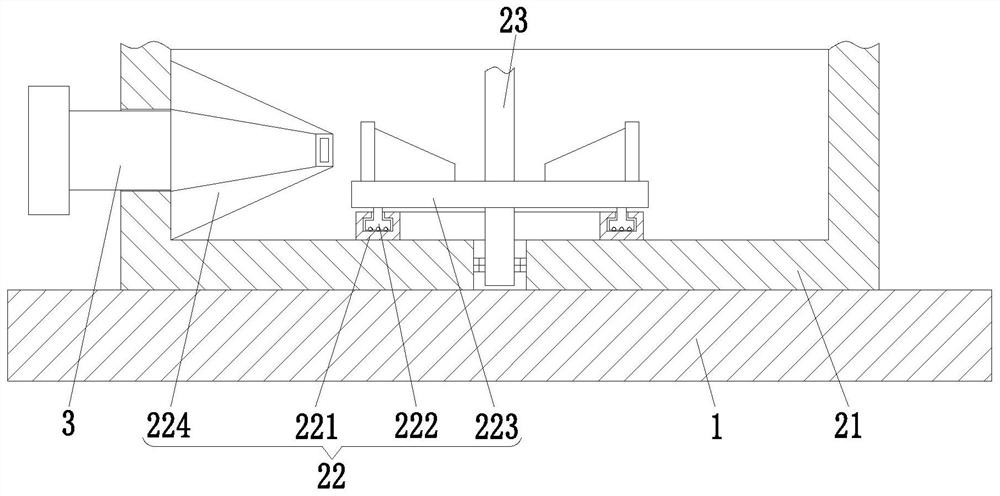

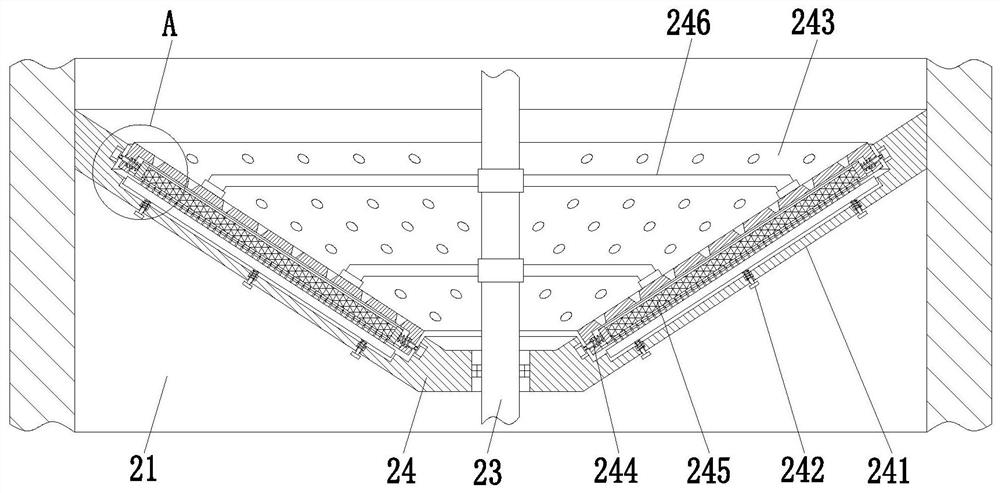

[0028] Such as Figure 1 to Figure 6 As shown, an exhaust gas treatment device in a painting workshop includes a bottom plate 1, a treatment device 2 and an air intake pipe 3. A treatment device 2 is installed on the upper end of the bottom plate 1. The treatment device 2 has a cylindrical structure, and the left lower end of the treatment device 2 is An air inlet is provided, and an air inlet pipe 3 is installed on the air inlet.

[0029] The processing device 2 includes a housing frame 21, a rotating mechanism 22, a rotating shaft 23, a processing mechanism 24 and a purification layer 25. The housing frame 21 is installed in the middle of the upper end of the bottom plate 1, and the cross section of the housing frame 21 is rectangular and hollow. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap