Noctilucent ultrafine particle heating and stirring equipment for noctilucent textiles

A technology of ultra-fine particles, heating and stirring, applied in heat treatment, chemical/physical/physicochemical fixed reactors, melting, etc., can solve the problems of small application range, poisonous and harmful, environmental pollution, etc., to improve the stirring effect, improve Practicality and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

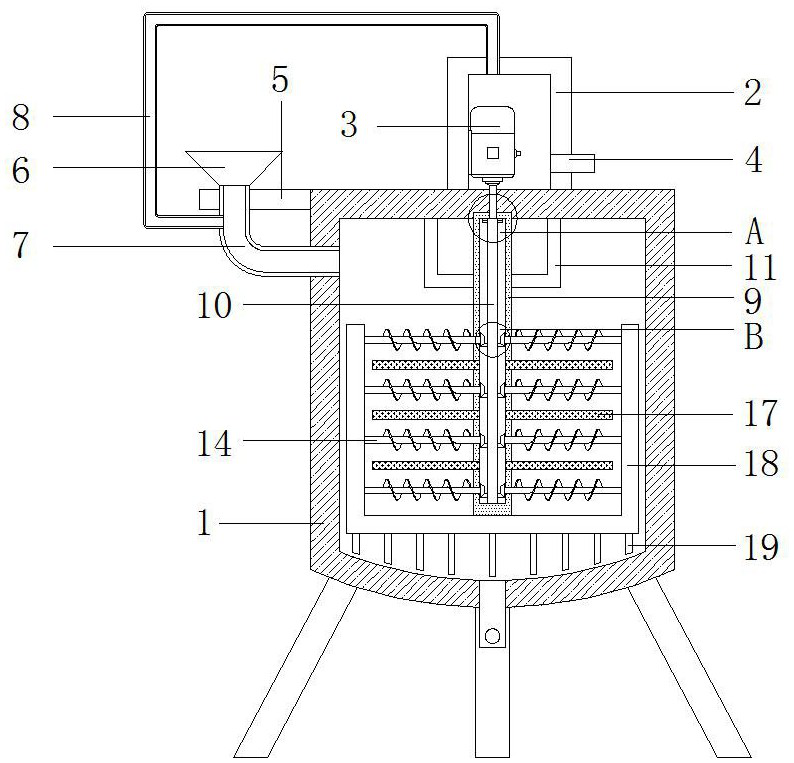

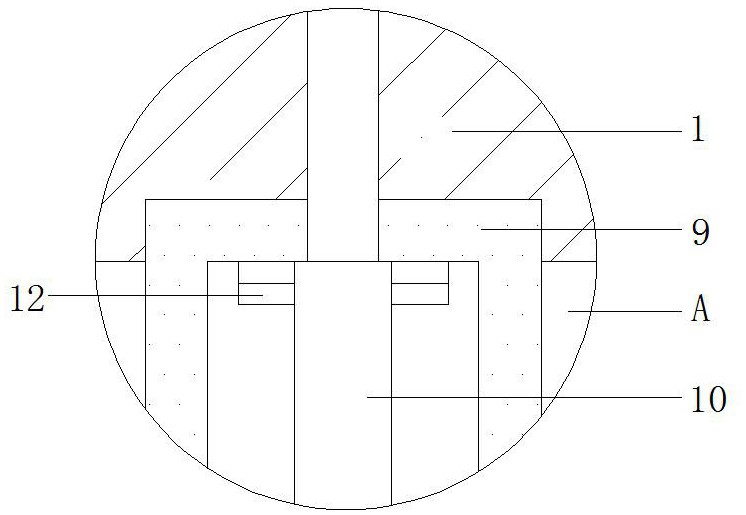

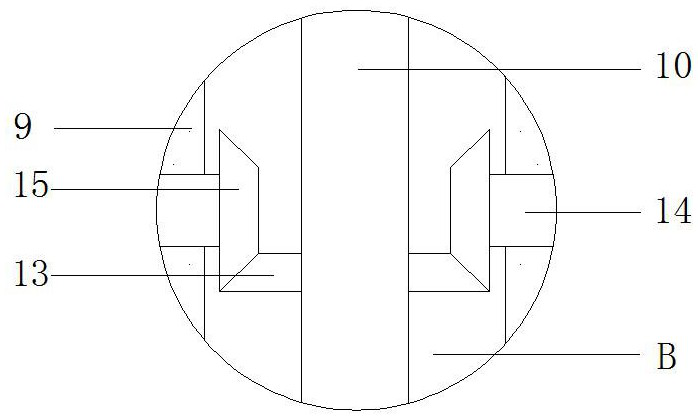

[0023] Embodiment 1, with reference to Figure 1-5 , a kind of heating and stirring equipment for luminous ultrafine particles for luminous textiles, comprising a thermal insulation shell 1, the outer walls of the four corners of the bottom of the thermal insulation shell 1 are welded with supporting legs, and the outer walls of the bottom ends of the four supporting legs are fixedly connected with An anti-skid pad, an installation box 2 is welded on the top outer wall of the thermal insulation shell 1, and a motor 3 is connected to the inner wall of one side of the installation box 2 by bolts, and an air inlet is opened on the inner wall of the installation box 2 away from the motor 3 A one-way air intake valve 4 is socketed on the inner wall of the air inlet, a connecting plate 5 is welded on the outer wall of one side of the heat preservation shell 1, and a feeding hopper 6 is socketed on the outer wall of one end of the top of the connecting plate 5, A feeding pipe 7 is so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com