Semiautomatic sunflower turning machine

A sun flower machine, semi-automatic technology, applied in the direction of turning equipment, turning equipment, metal processing machinery parts, etc., can solve problems such as easy bonding, lower production efficiency, and troublesome demoulding, so as to reduce operation steps and improve production efficiency , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

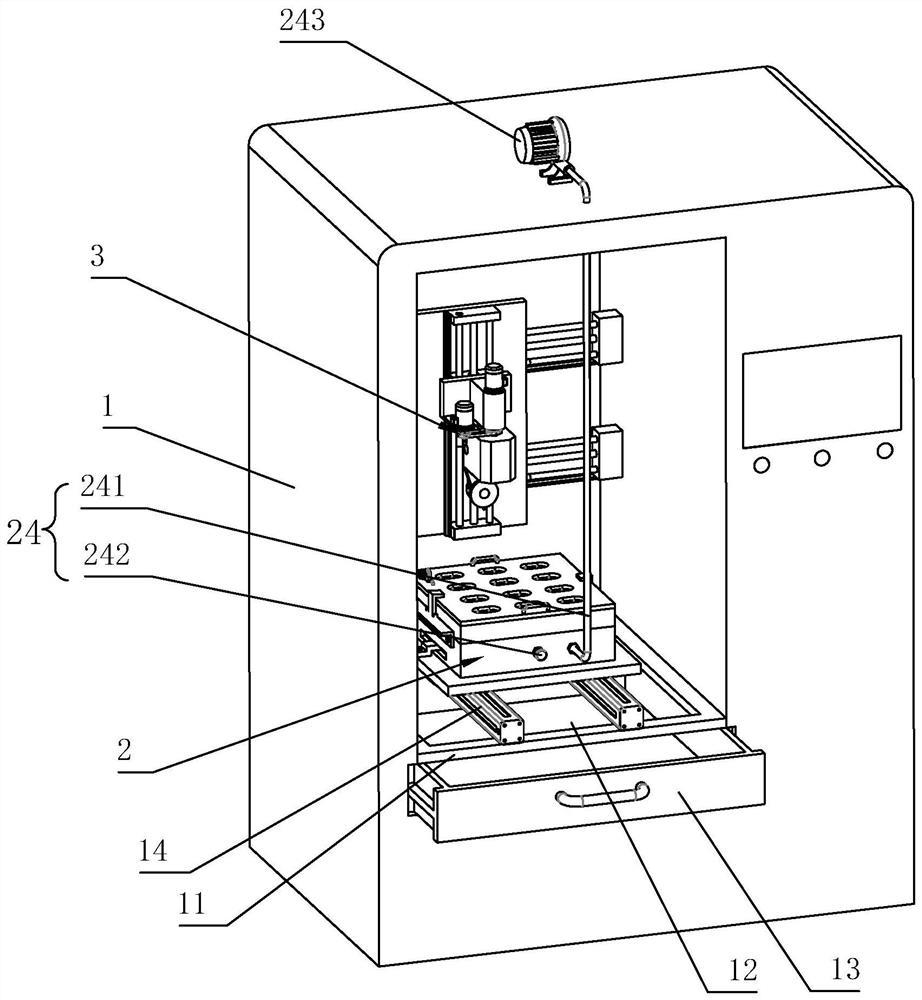

[0050] refer to figure 1 , a semi-automatic car sun flower machine, comprising a frame 1, a material positioning device 2 arranged on the frame 1, and a car embossing device 3 arranged on the frame 1 to carry out car embossing to the material, and a car embossing device 3 Located above the sheet positioning device 2.

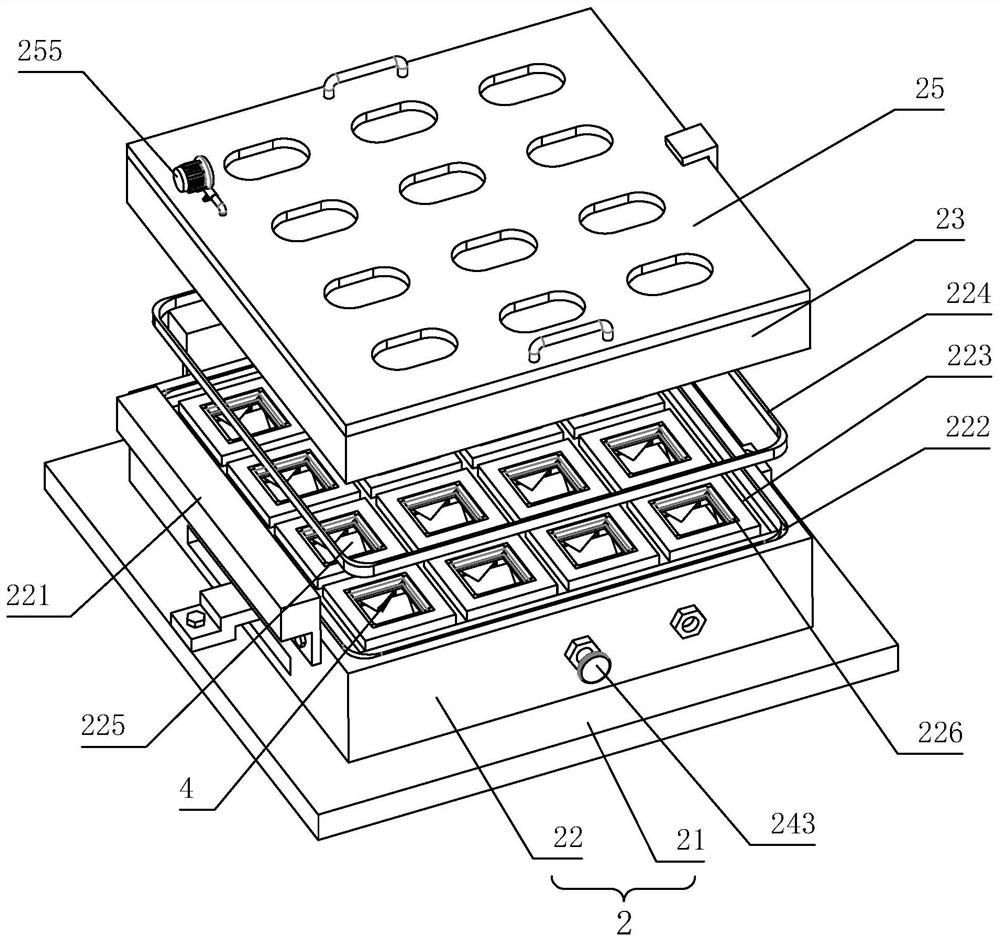

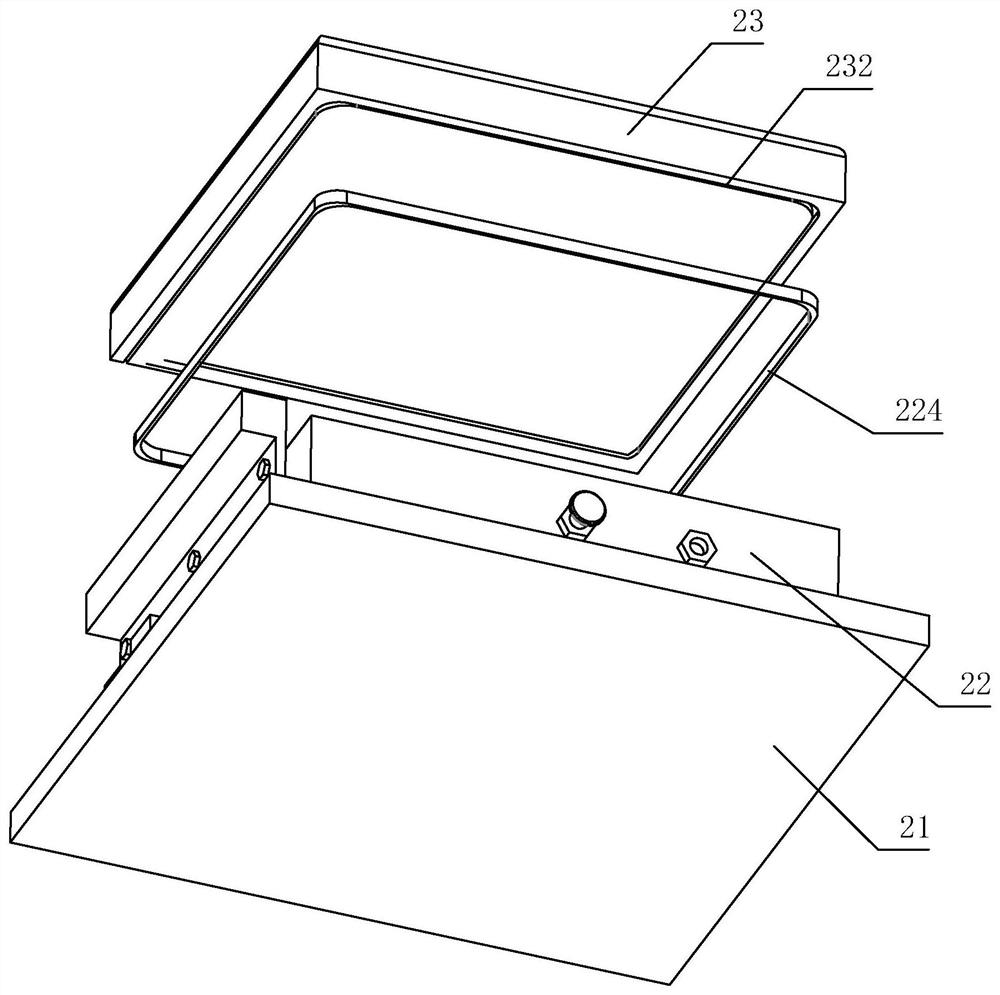

[0051] refer to figure 1 , figure 2 The frame 1 is provided with a support frame 11 and a chip box 13 whose upper part is open and located below the support frame 11. The chip box 13 is slidably connected to the frame 1 in the longitudinal direction, and the support frame 11 is opened to communicate with the chip box. The chip opening 12 of the box 13. The tablet positioning device 2 includes a mounting plate 21 longitudinally slidably connected to the support frame 11, an adsorption template 22 arranged in a cavity and installed on the installation plate 21, and a positioning template placed on the adsorption template 22 for placing tablets. 23 and a fixed...

Embodiment 2

[0065] The difference with embodiment 1 is: refer to Figure 14 , Figure 15 , the lower end surface of the positioning template 23 protrudes and is provided with a plug-in piece 6 inserted in the second adsorption hole 225, and the plug-in piece 6 includes a connecting column 61 protruding vertically and fixedly connected to the lower end surface of the positioning template 23 and a fixed The guide post 62 connected to the lower end of the connecting post 61, the cross section of the connecting post 61 and the guide post 62 is square, the guide post 62 is tapered, the upper end of the guide post 62 is a large end and the lower end of the guide post 62 is a small end. The connecting column 61 is surrounded by a third sealing groove 611 along the circumference, and the third sealing groove 611 is embedded with a second sealing strip 612. When the connecting column 61 is inserted into the second adsorption hole 225, the second sealing strip 612 abuts against on the end face of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com