Clamping and unloading mechanism

A technology of clamping unloading and ejecting mechanism, which is applied in the direction of conveyor objects, metal processing, transportation and packaging. The effect of increasing the strength and improving the suction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

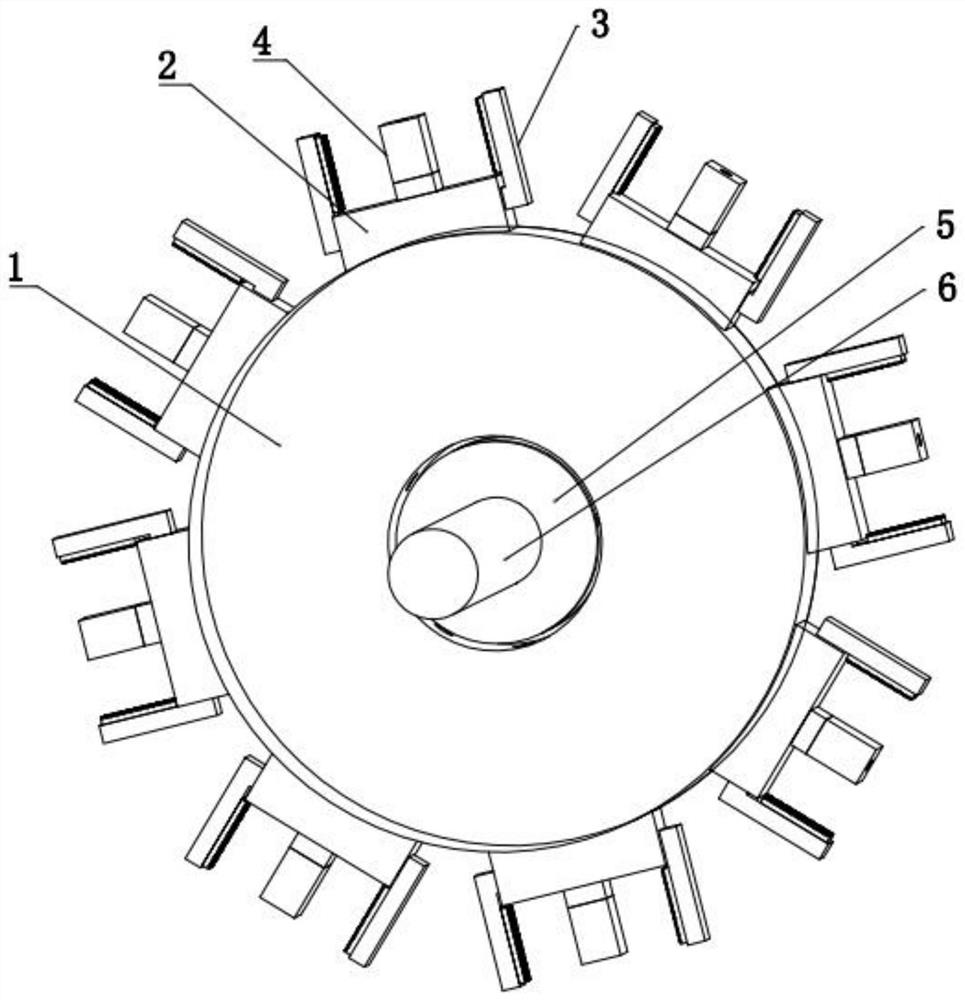

[0029] A clamping and unloading mechanism, referring to Figure 1-Figure 4 As shown, it includes a fixed disc 1, which can be fixed on the mechanical equipment or on the support. On the outer ring wall of the disc 1, a number of fixed blocks 2 are evenly spaced in the circumferential direction and fixed on the fixed block. 2 is provided with clamping blocks 3 that can approach or move away from each other, and on the fixed block 2 at the center of the distance between the two clamping blocks 3, a clamping and suction ejecting mechanism is provided.

[0030] Wherein, the specific structure of clamping block 3 and fixed block 2 is as follows, clamping block 3 overall is " L " shape, the both sides of fixed block 2 is sunken with guiding groove 21, and the bottom of clamping block 3 telescopically is arranged in guiding groove 21, in A clamping spring 10 is fixedly arranged between the bottom of the clamping block 3 and the bottom of the guide groove 21 . In addition, an elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com