A kind of formaldehyde-free antibacterial bamboo straw composite substrate and preparation method thereof

A composite base material and antibacterial bamboo technology, which is applied in the direction of flat products, lignin adhesives, adhesive types, etc., can solve the problems of restricting the application of particleboard, difficulty in using it as a floor base material, and complicated preparation process, so as to reduce forest trees The use of resources, the reduction of TVOC emissions, and the effect of reducing TVOC content

Active Publication Date: 2022-06-10

BEIJING FORESTRY UNIVERSITY

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

After coating the antibacterial layer, the surface of the particleboard is prone to roughness and dents, which not only increases the difficulty of the preparation process, but also makes it difficult to carry out finishing treatment on the particleboard base material coated with the antibacterial layer, which limits the application of particleboard

[0005] At present, the commonly used floor substrates on the market use plywood, fiberboard or oriented strand board as raw materials, and the preparation process is complicated and the cost is high.

And the surface of the floor substrate prepared by oriented strand board is uneven

Ordinary particleboard has low density and low strength, so it is difficult to be used as a floor substrate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

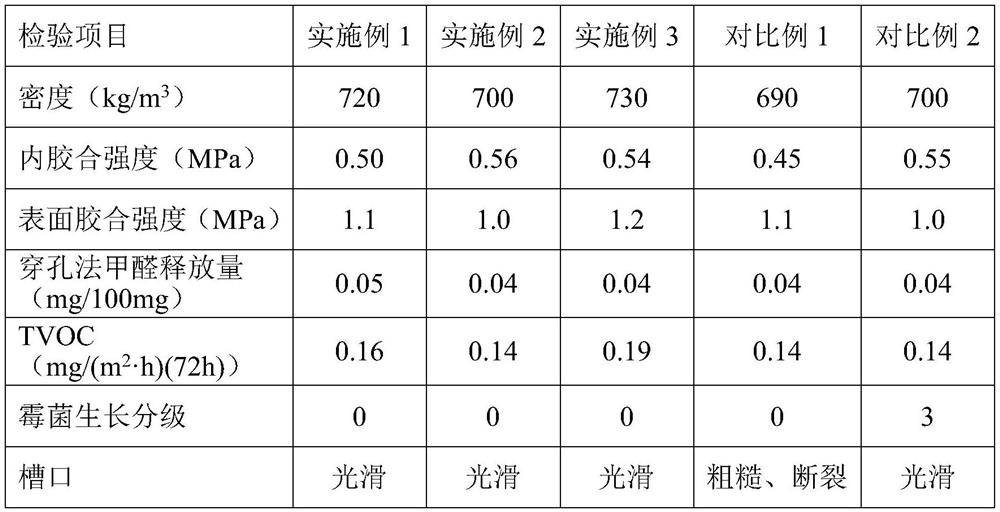

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a formaldehyde-free antibacterial bamboo straw composite substrate and a preparation method thereof, wherein the preparation method includes in-situ preparation of an antibacterial adhesive: using lignin to reduce silver ions in situ to generate nano-silver to obtain an antibacterial adhesive Preparation of composite base material: the base material includes bamboo scraps and / or straw scraps with a length of 0.3-20.0mm and a thickness of 0.3-0.7mm, which are mixed to obtain a mixture of surface layer and core layer; aldehyde-free antibacterial Preparation of bamboo straw composite substrate: mix and sizing the upper surface layer mixture, the lower surface layer mixture and the core layer mixture with antibacterial adhesive and / or isocyanate adhesive respectively to obtain the sizing For mixing materials, the mixed materials after sizing are paved, hot-pressed and post-treated to obtain the formaldehyde-free antibacterial bamboo straw composite base material. The method provided by the invention makes full use of the existing bamboo and straw resources, and the prepared composite base material has extremely low formaldehyde emission, meets the requirements of the "formaldehyde-free wood-based panels and their products" standard, and has excellent antibacterial properties.

Description

Formaldehyde-free antibacterial bamboo straw composite substrate and preparation method thereof technical field The present invention relates to a kind of composite base material, particularly relate to a kind of aldehyde-free anti-oxidant produced by utilizing bamboo scraps and straw scraps. A mushroom-bamboo-straw composite base material and a preparation method thereof belong to the field of composite material preparation. Background technique [0002] The annual consumption of wood in my country has reached more than 600 million cubic meters, and the external dependence of wood exceeds 50%, and the gap is as high as 2.5%. One hundred million cubic meters. my country is the world's largest producer and consumer of wood-based panels, with an annual output of nearly 300 million cubic meters. exist objectively and increasingly Under the huge pressure of the growing demand for wood products, the state's attitude towards "protecting forest resources" has become increasin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B27N3/08B27N3/00B27N3/14C09J197/00C09J11/04

CPCB27N3/08B27N3/002B27N3/14C09J197/005C09J11/04C08K2003/0806C08K2201/011C08K3/08

Inventor 庞博袁同琦范文明姜志华王素鹏赵宝成陈月英

Owner BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com