Low-emission TVOC foamed polypropylene product and preparation method thereof

A foamed polypropylene, low-emission technology, applied in the field of polypropylene products, can solve problems affecting human health, achieve the effect of uniform cells and increase strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

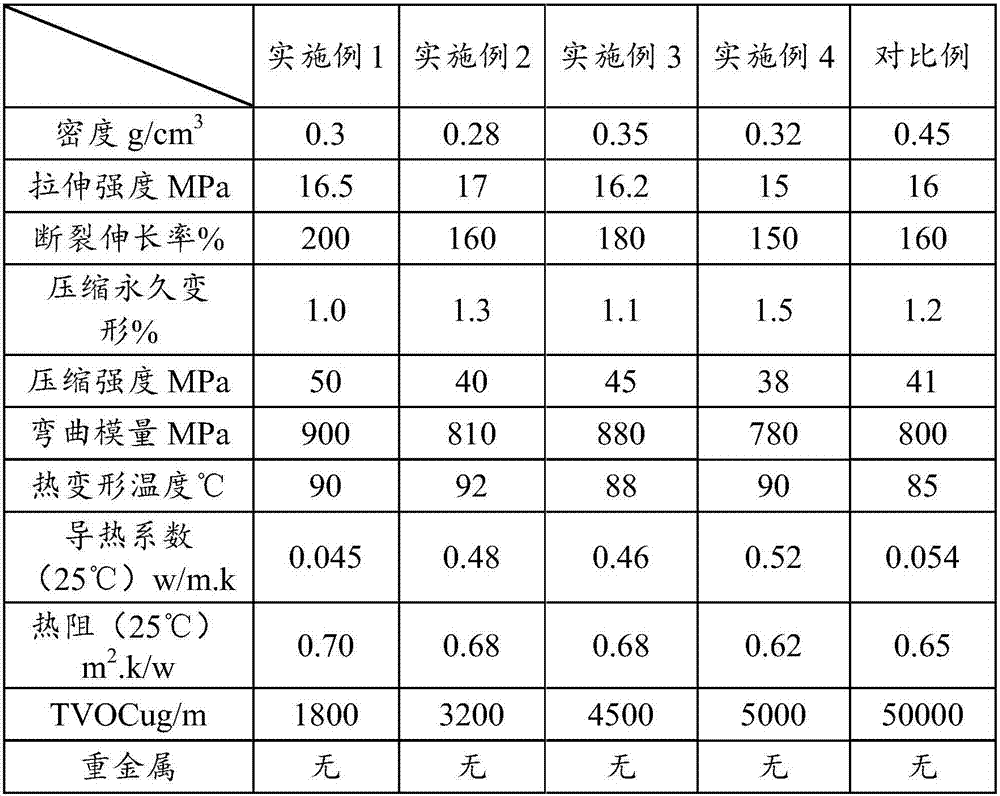

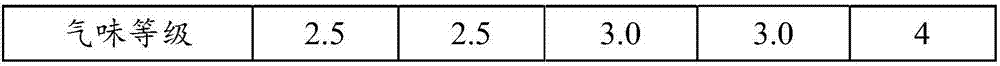

Examples

preparation example Construction

[0024] A method for preparing low-emission TVOC foamed polypropylene products, comprising: mixing polypropylene resin and fibers, then mixing with porous absorbent materials and coupling cross-chaining agents to form a mixture, and heating the mixture at a temperature of 160-210°C Foaming under the action of nitrogen after extrusion.

[0025] The polypropylene resin and fiber do not react when mixed, and the polypropylene resin and fiber can be fully mixed evenly, which is conducive to the uniform distribution of the fiber in the foamed polypropylene product, and can make the foamed cells more uniform. After the polypropylene resin is mixed with the fiber, it is mixed with the porous absorbent material and the coupling cross-linking agent, and then melted into a melt at a temperature of 160-210 ° C, extruded after the cross-linking reaction, and then under the action of nitrogen Foaming. In an embodiment of the present invention, the purity of nitrogen is greater than or equa...

Embodiment 1

[0030] A low-emission TVOC foamed polypropylene product, which is mainly made by foaming raw materials with nitrogen as a foaming gas. In parts by weight, the raw materials include: 80 parts by weight of polypropylene resin, 10 parts by weight of coupling cross-chaining agent, 1 part by weight of silicone powder, 5 parts by weight of magnesium salt whiskers with a diameter of 20 nm and an aspect ratio of 80, 2 parts by weight of polyphosphate porous material, 0.3 parts by weight of antioxidant 1010 and 3,5-di-tert-butyl - 0.1 parts by weight of n-hexadecyl 4-hydroxybenzoate. Among them, the polypropylene resin is composed of hyperbranched polypropylene, homopolypropylene and copolymerized polypropylene with a mass ratio of 1:3:4; the coupling cross-linking agent is composed of PP-gMAH, EPDM with a mass ratio of 10:9:1 and MBA composition.

[0031] The preparation method of the low-emission TVOC foamed polypropylene product comprises: after fully mixing polypropylene resin and...

Embodiment 2

[0033] A low-emission TVOC foamed polypropylene product, mainly made of raw materials foamed with nitrogen as a foaming gas, in parts by weight, the raw materials include: 70 parts by weight of polypropylene resin, 15 parts by weight of coupling cross-chaining agent, 1.5 parts by weight of nanographite, 10 parts by weight of calcium carbonate whiskers with a diameter of 20 nm and an aspect ratio of 80, 1 part by weight of polyphosphate porous material, 0.3 parts by weight of antioxidant 1010 and 3,5-di-tert-butyl- 0.1 parts by weight of n-hexadecyl 4-hydroxybenzoate. Among them, the polypropylene resin is composed of hyperbranched polypropylene, homopolypropylene and copolymerized polypropylene with a mass ratio of 1:5:10; the coupling cross-linking agent is composed of PP-gMAH, EPDM with a mass ratio of 6:13:1 and MBA composition.

[0034] The preparation method of the low emission TVOC foamed polypropylene product comprises: after fully mixing polypropylene resin and calciu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com