Formaldehyde-free antibacterial bamboo straw composite base material and preparation method thereof

A composite substrate and antibacterial bamboo technology, which is applied in the direction of flat products, adhesive types, lignin adhesives, etc., can solve the problems of restricting the application of particleboard, difficulty in using it as a floor substrate, and high cost, and achieve the goal of reducing forest resources Use, reduce TVOC content, reduce the effect of TVOC emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

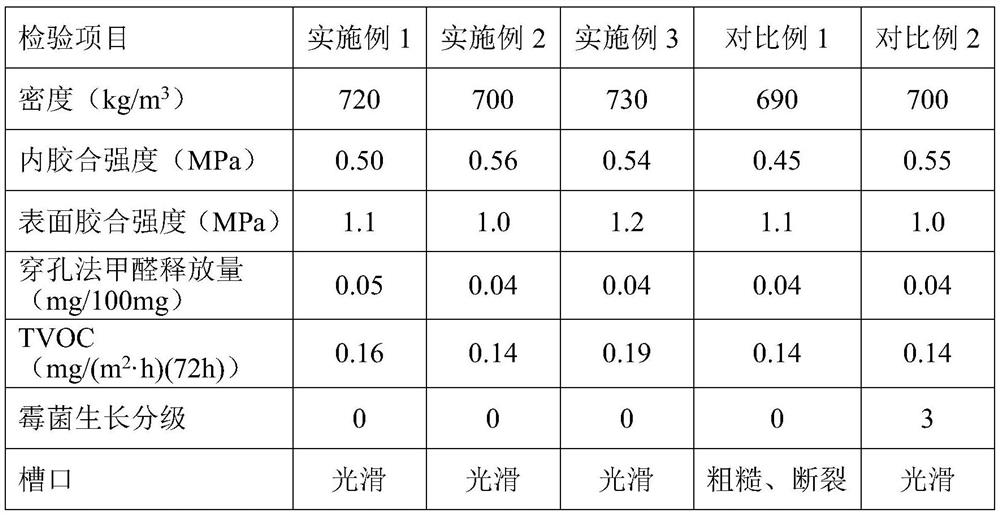

Examples

Embodiment 1

[0024] (1) In-situ preparation of antibacterial adhesives: In the process of preparing lignin-based adhesives from Lvda New Materials Co., Ltd., alkaline silver ion solution is added, and the mass of silver ions is the mass of lignin-based adhesives 0.005%. After adding the alkaline silver ion solution, the reaction temperature is 75° C., and the reaction time is 1.0 h.

[0025] (2) Preparation of composite base material: Moso bamboo scraps with a moisture content of 7%, a length of 0.3 mm, and a thickness of 0.3 mm were used as base materials for the upper and lower surface layers and the core layer. The mass ratio of the upper and lower surface layer mixture to the core layer mixture is 4:6.

[0026] (3) Preparation of formaldehyde-free antibacterial bamboo straw composite substrate: add 12% antibacterial adhesive to the upper and lower surface layers, and add 7% lignin-based adhesive from Hunan Lvda New Material Co., Ltd. to the core layer agent. The mixed material after...

Embodiment 2

[0029] (1) In-situ preparation of antibacterial adhesives: In the process of preparing lignin-based adhesives from Lvda New Materials Co., Ltd., alkaline silver ion solution is added, and the mass of silver ions is the mass of lignin-based adhesives of 0.004%. After adding the alkaline silver ion solution, the reaction temperature is 75° C., and the reaction time is 1.0 h.

[0030] (2) Preparation of composite base material: Moso bamboo scraps and rice straw scraps with a moisture content of 7%, a length of 0.5 mm, and a thickness of 0.5 mm were used as base materials for the upper and lower surface layers and the core layer. The moso bamboo scraps and the rice straw scraps are evenly mixed in a mass ratio of 7:3. The mass ratio of the upper and lower surface layer mixture to the core layer mixture is 4:6.

[0031] (3) Preparation of formaldehyde-free antibacterial bamboo straw composite substrate: add 12% antibacterial adhesive to the upper and lower surface materials, and ...

Embodiment 3

[0034](1) In-situ preparation of antibacterial adhesives: In the process of preparing lignin-based adhesives from Lvda New Materials Co., Ltd., alkaline silver ion solution is added, and the mass of silver ions is the mass of lignin-based adhesives of 0.004%. After adding the alkaline silver ion solution, the reaction temperature is 80° C., and the reaction time is 2.0 h.

[0035] (2) Preparation of composite base material: Moso bamboo scraps and rice straw scraps with a moisture content of 7%, a length of 5 mm, and a thickness of 0.3 mm were used as base materials for the upper and lower surface layers. The moso bamboo scraps and the rice straw scraps are evenly mixed in a mass ratio of 7:3. Take the moso bamboo fragments with a moisture content of 7%, a length of 10mm and a thickness of 0.7mm as the base material of the core layer. The mass ratio of the upper and lower surface layer mixture to the core layer mixture is 4:6.

[0036] (3) Preparation of formaldehyde-free an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com