Anti-caking mud cake circulating system for slurry balance shield tunneling machine and shield tunneling machine

A circulation system and mud-water balance technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of shield machines not being able to excavate normally, project progress delayed and overdue, and enterprise losses, etc., to prevent ground slurry and uplift subsidence accidents, improving safety and reliability, and satisfying the effect of tunneling needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

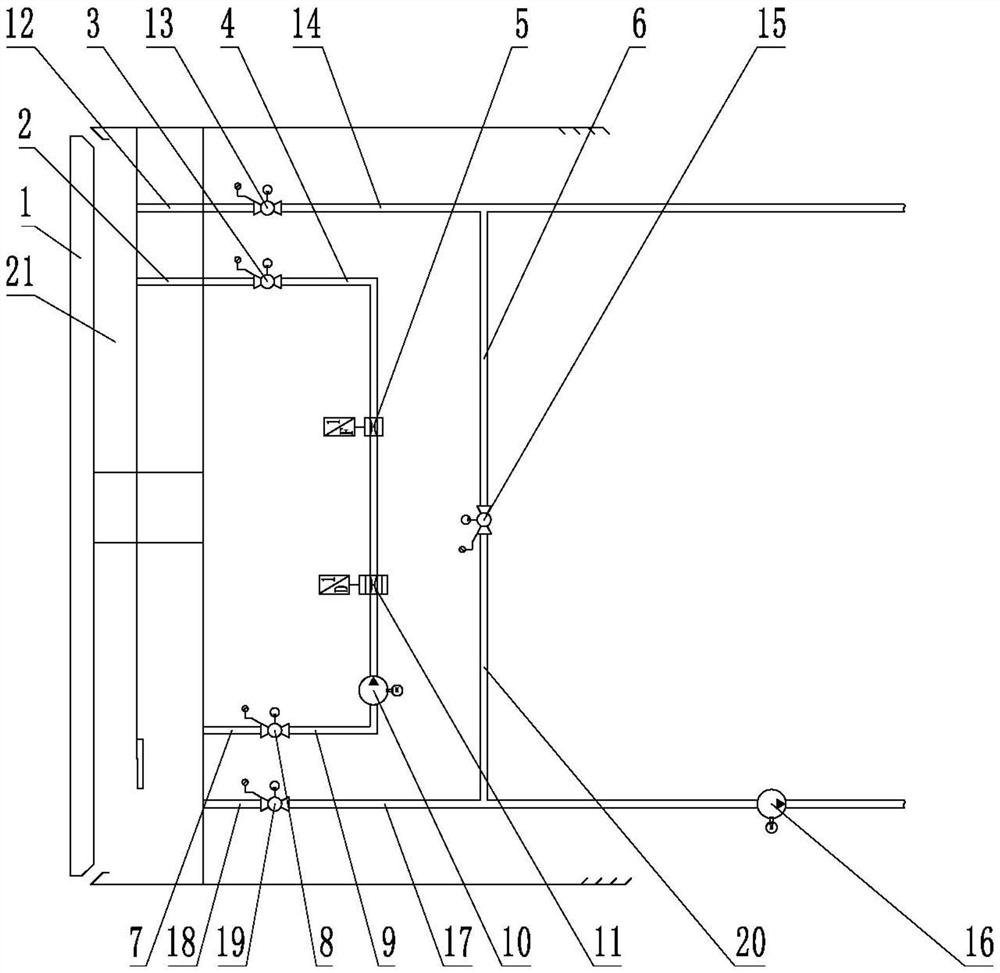

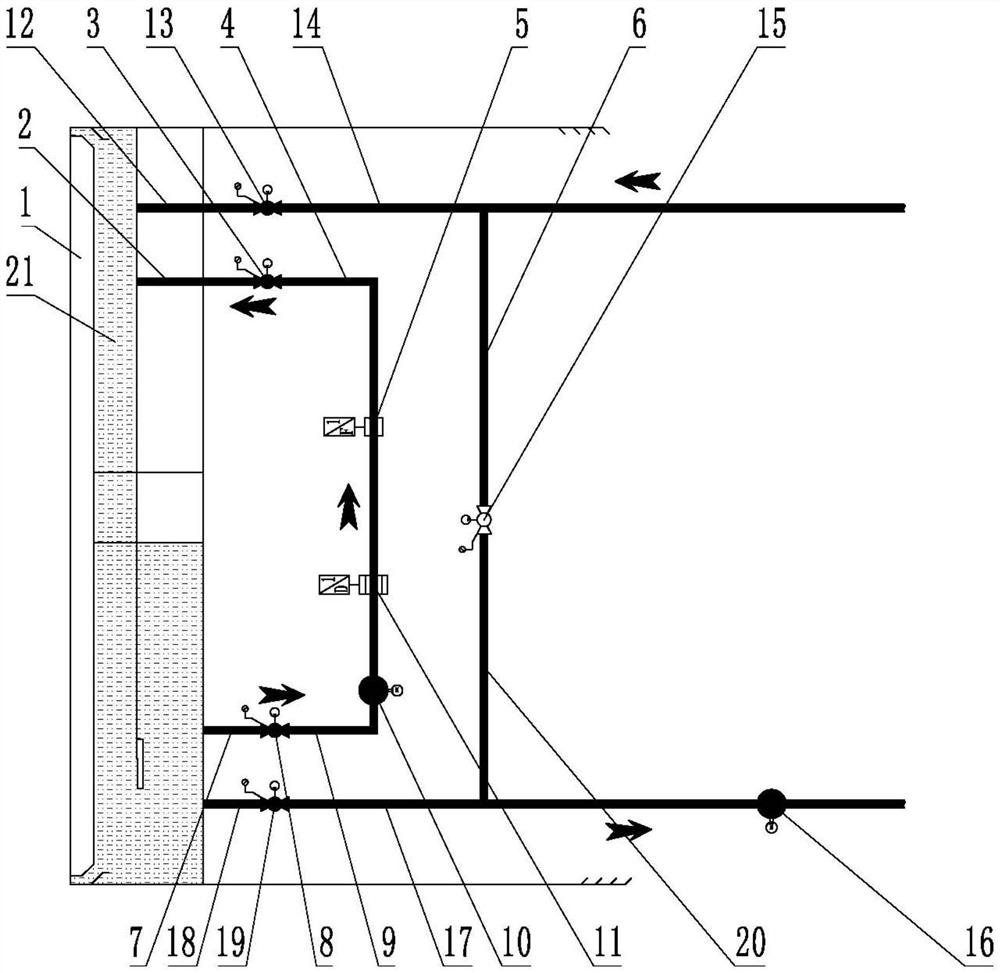

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0020] like figure 1 As shown, an anti-sludge cake circulation system for a mud-water balance shield machine includes a circulating slurry pump 10, a slurry inlet pipe control valve I8, a slurry discharge pipe control valve I3, a slurry inlet circulation pipeline I7, and a slurry inlet circulation Pipeline II9, pulp discharge circulation pipeline I4 and pulp discharge circulation pipeline II2. One end of the slurry feeding circulation pipeline I7 is connected to the opening of the slurry feeding circulation pipe near the bottom of the slurry tank 21, and the other end of the slurry feeding circulation pipeline I7 is connected to one end of the slurry feeding pipe control valve I8, and the slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com