Gypsum-containing stratum railway tunnel anti-release combined supporting structure and construction method thereof

A technology of supporting structure and construction method, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problem of high engineering cost, reduce engineering cost, reduce the impact of external loads, and save engineering investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

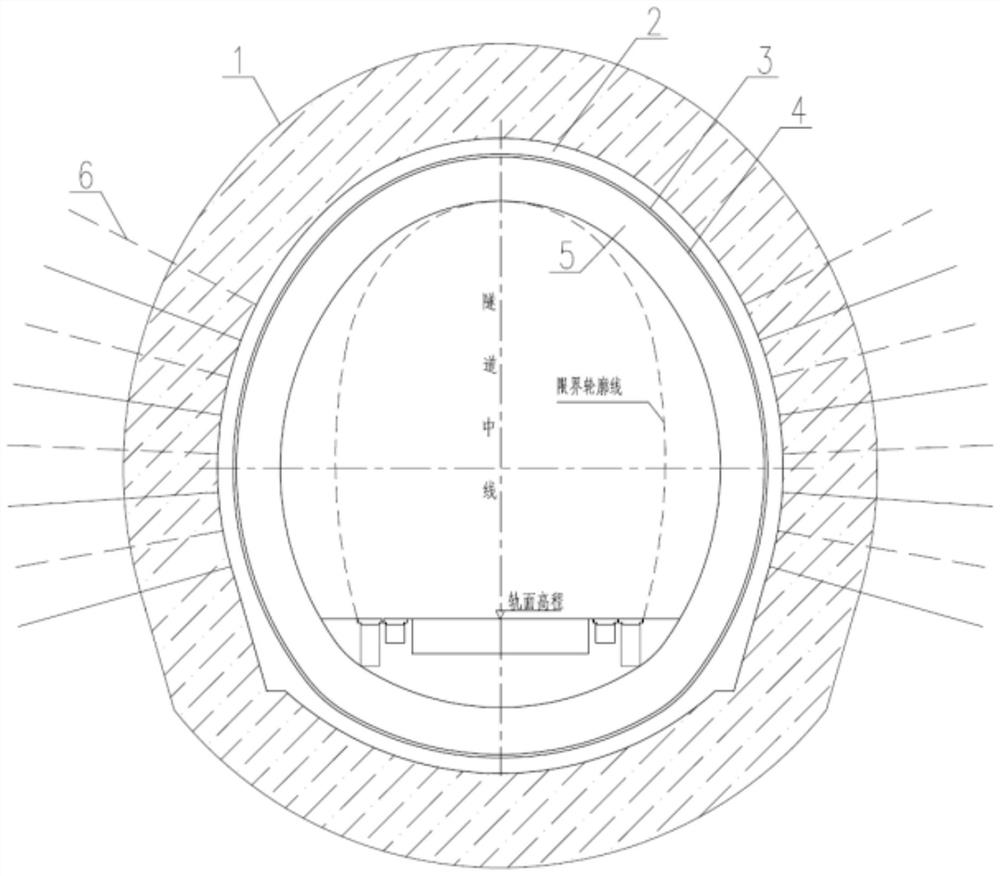

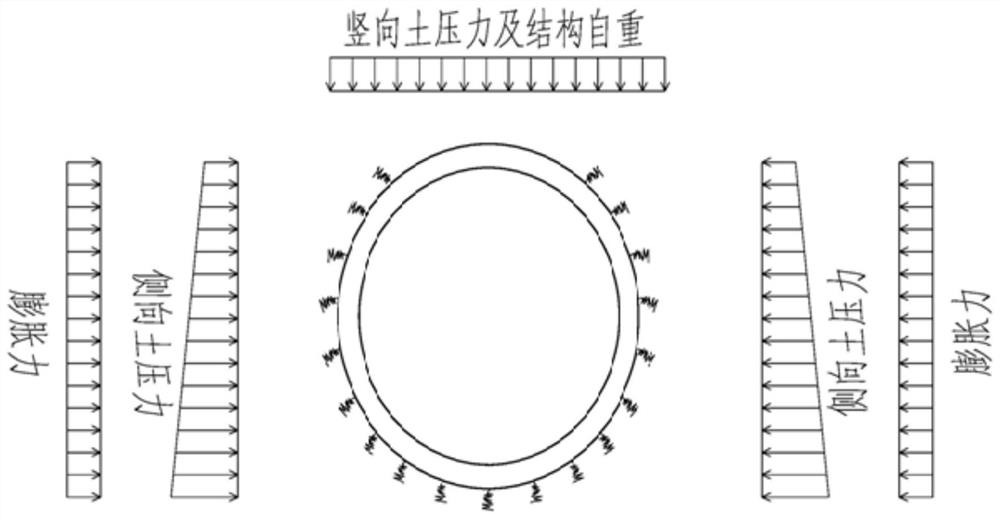

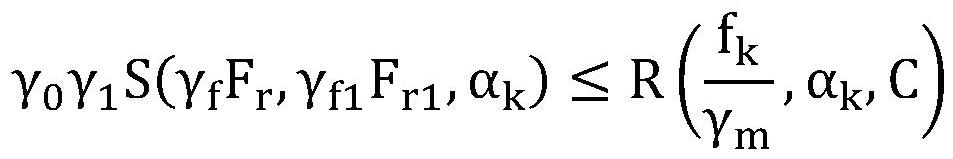

[0025] Embodiments of the present invention provide a kind of gypsum stratum railway tunnel anti-discharge combined support structure, such as figure 1 As shown, it includes surrounding surrounding rock reinforcement layer 1, primary support structure 2 and secondary lining structure 5 arranged sequentially from outside to inside, prestressed anchor rod 6 is inserted into said surrounding surrounding rock reinforcement layer 1, and said primary support A buffer layer 3 and a waterproof layer 4 are arranged between the structure 2 and the second lining structure 5, and the waterproof layer 4 is located inside the buffer layer 3. The cross section of the primary support structure 2 and the second lining structure 5 is an elliptical r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com