A multifunctional compact lock valve with precise flow control

A flow control, multi-functional technology, applied in valve details, valve device, valve shell structure, etc., can solve the problems of air stagnation, adjustment failure, and household heating is not too large, to achieve defensive improvement, precise control, Professional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

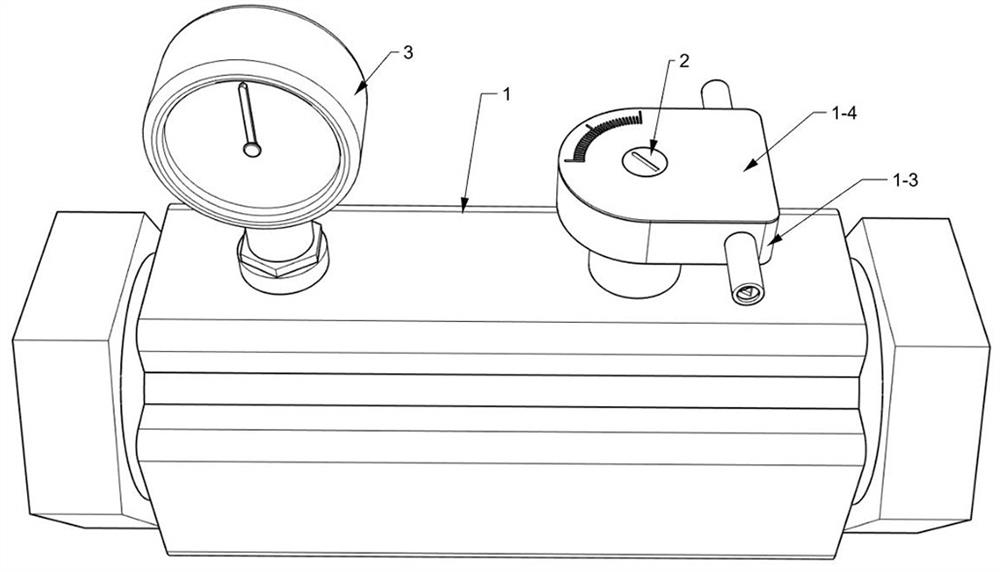

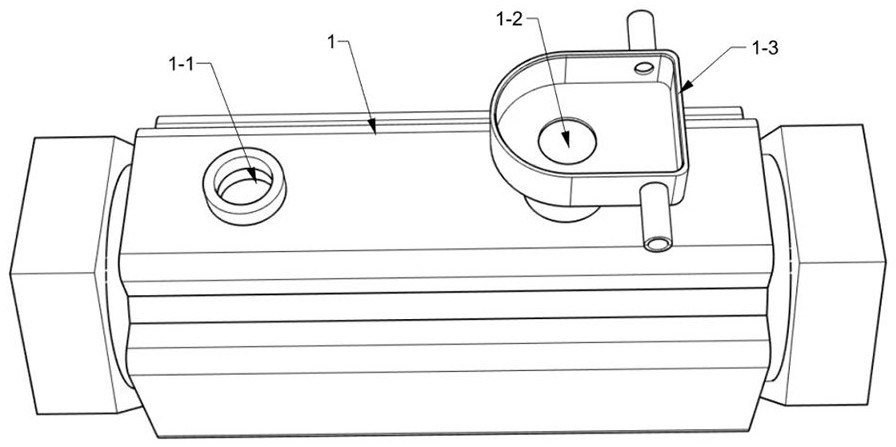

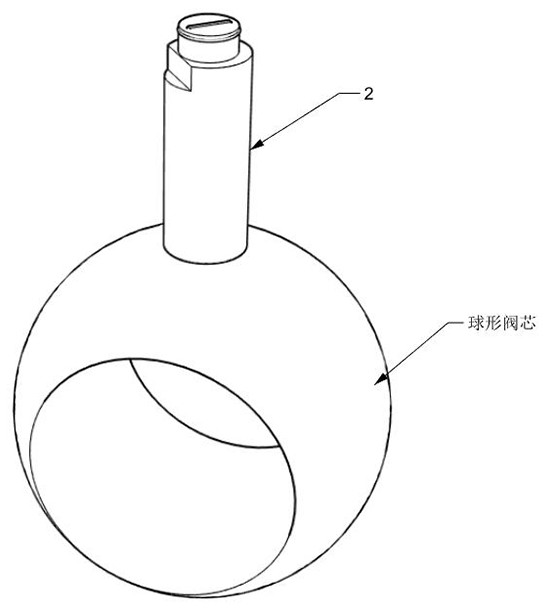

[0047] Please refer to Figure 1-7 , the present application discloses a multi-functional and compact locking valve that precisely controls the flow. The locking valve can precisely control the flow of the fluid, so as to achieve precise temperature regulation, and at the same time, the locking valve can also display the water temperature in the pipe. The locking valve mainly includes a valve body 1, a valve stem 2, a temperature display meter or a heat meter 3, and the specific structural features are as follows:

[0048] A through hole 1-1 is arranged on the valve body 1 along the radial direction, the through hole 1-1 extends to the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com